Surface mounting tool applied to microphone element

A mounting tool and microphone technology, which is applied to the assembly of printed circuits, electrical components, and printed circuits with electrical components, can solve the problems of solder beads and affect the electrical performance of PCB boards, so as to reduce the amount of solder paste and avoid solder beads phenomenon, the effect of ensuring electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

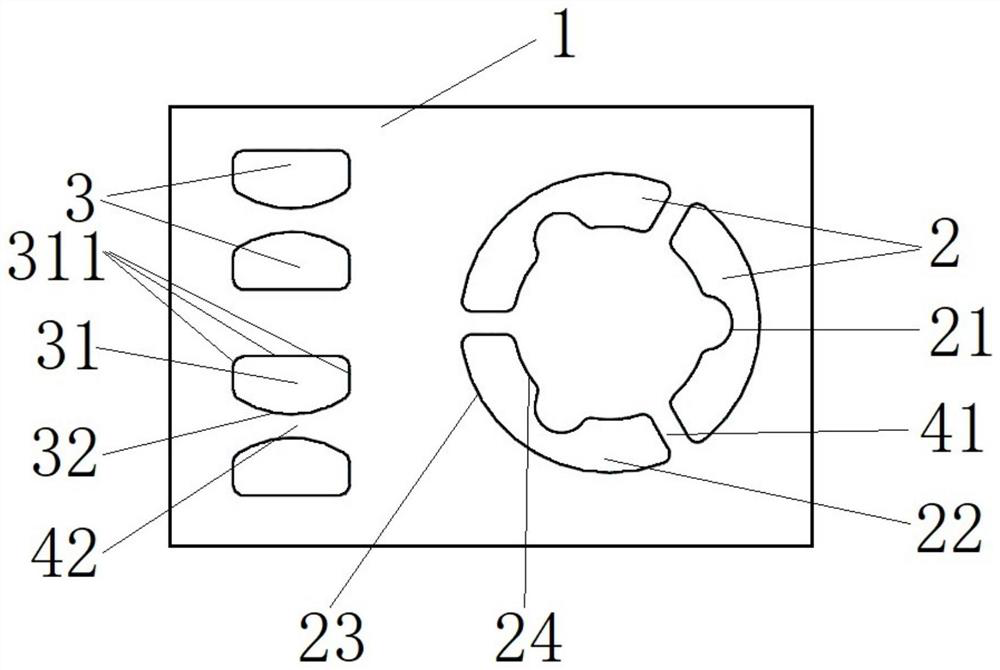

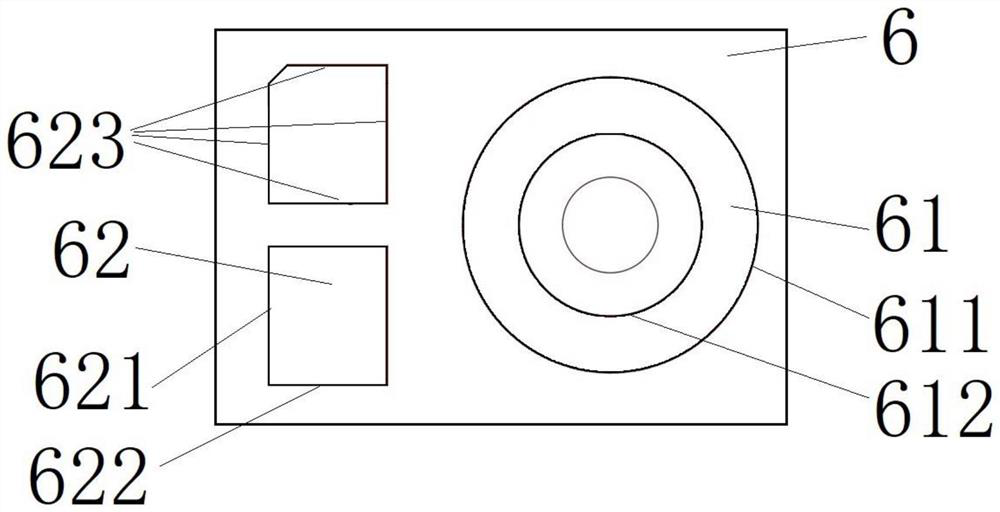

[0037] like figure 1 and figure 2 The shown placement tool applied to microphone components includes a placement tool body 1 , an acoustic ring hole 2 and a signal hole 3 . By placing the mounting tool body 1 on the PCB board 6, the solder is laid through the acoustic ring hole 2 and the signal hole 3 on the image 3 On the PCB board 6 shown, the solder is reflowed as in Figure 4 Microphone element 5 shown.

[0038] For example, as Figure 1 to Figure 4As shown, the radius of the third outer edge 511 of the acoustic ring 51 of the microphone element 5 may be 0.725 mm or other values, and the radius of the third inner edge 512 of the acoustic ring 51 of the microphone element 5 may be 0.475 mm or other values; The size of the first intersection edge 521 of the signal pin 52 of the element 5 may be 0.65 mm or other values, and the size of the second intersection edge 522 of the signal pin 52 of the microphone element 5 may be 0.545 mm or other values. The radius of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com