Roll separator for processing closed-hole adhesive base material

A coiling machine and rubber-based technology, which is applied in the direction of winding strips, thin material processing, packaging, etc., can solve the problems of inconvenient disassembly and assembly, and increase the difficulty of disassembly and assembly by staff, so as to reduce friction and reduce disassembly and assembly. The effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

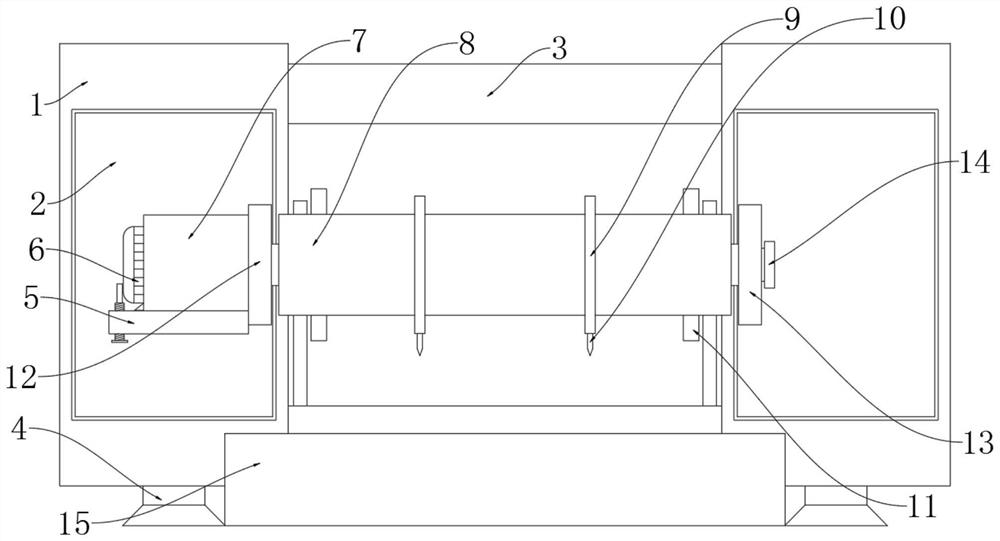

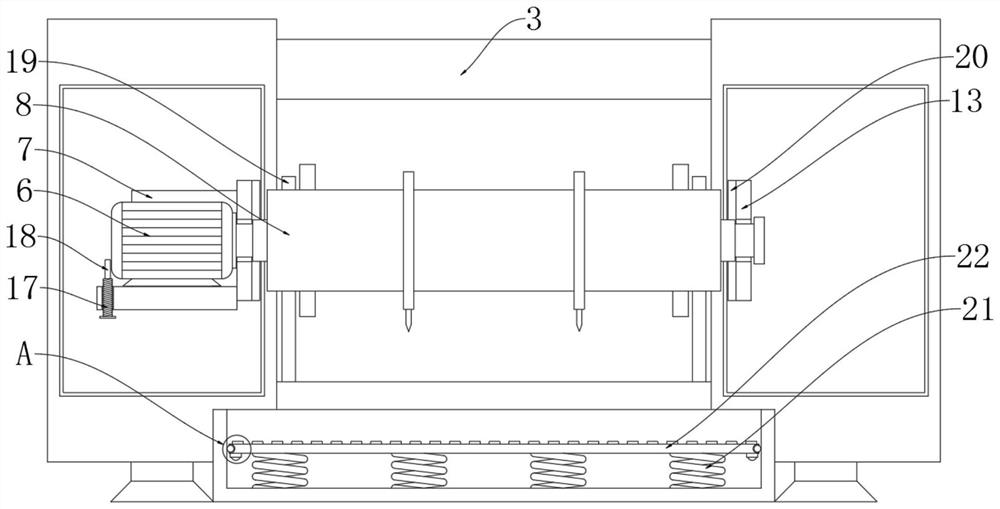

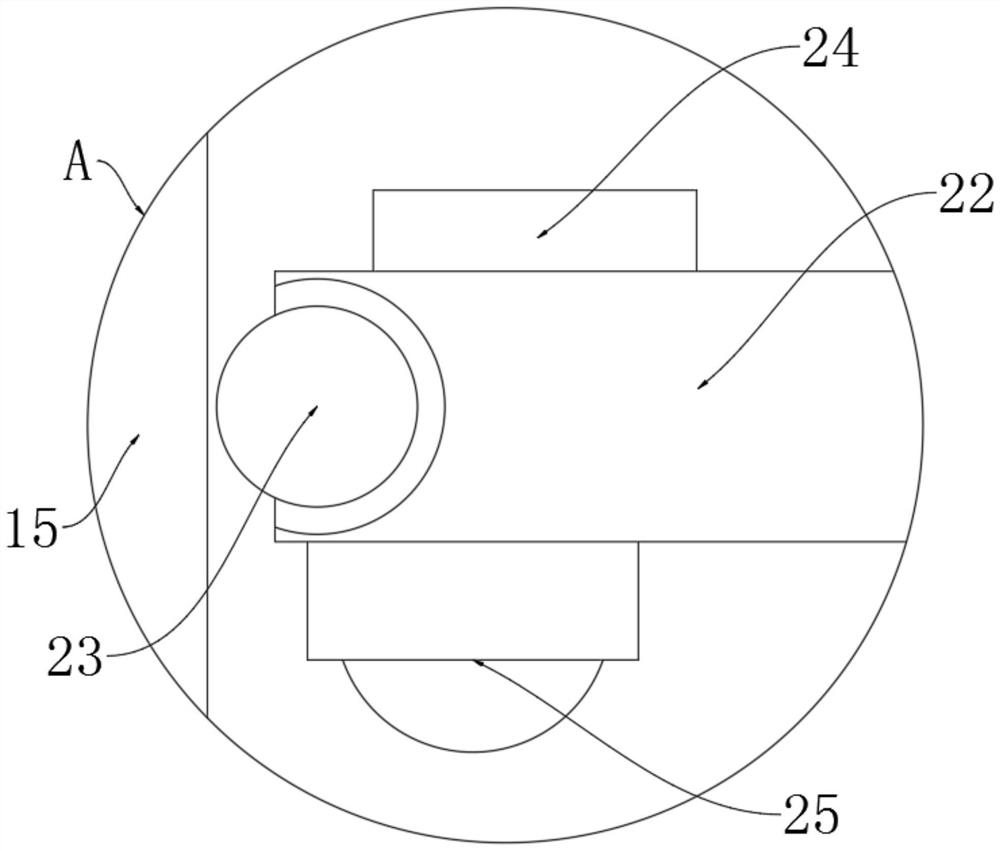

[0019] see Figure 1-3 , an embodiment provided by the present invention: a sub-coiler for the processing of closed-cell adhesive substrates, comprising a sub-coiler main body 1, one side of the sub-coiler main body 1 is provided with an inspection door 2, and the inspection door 2 is connected to The main body 1 of the sub-coiler is fixedly connected through the card slot, so that the connection between the inspection door 2 and the main body of the sub-coiler 1 is more firm. One end of the inspection door 2 is provided with a motor fixing vertical block 12, and the other end of the inspection door 2 is provided with a winding column Fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com