Manual pipe jacking unearthing trolley

A pipe jacking and manual technology, applied in the direction of motor vehicles, vehicle components, power units, etc., can solve problems such as being unsuitable for long-distance pipelines, and achieve the effects of reducing operation difficulty and labor intensity, convenient disassembly and assembly, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

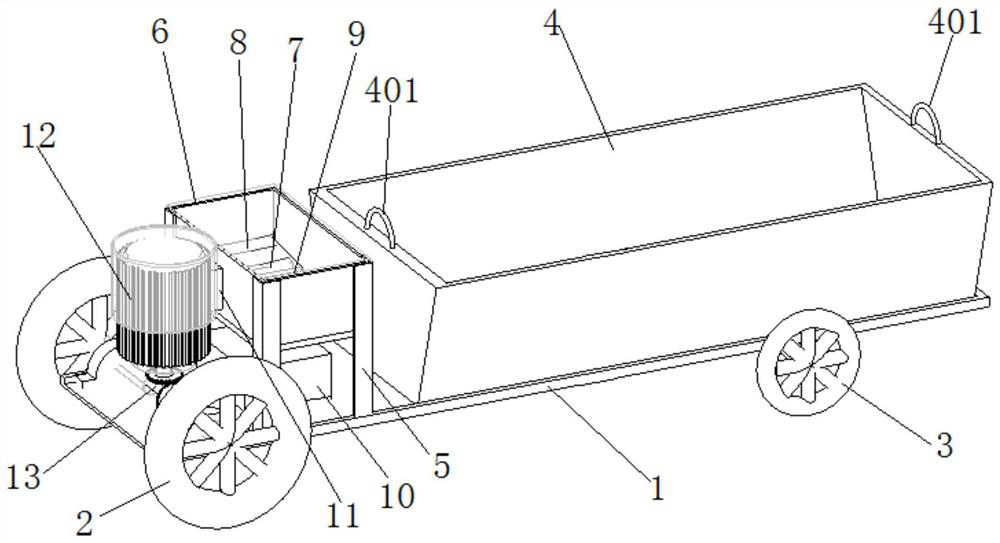

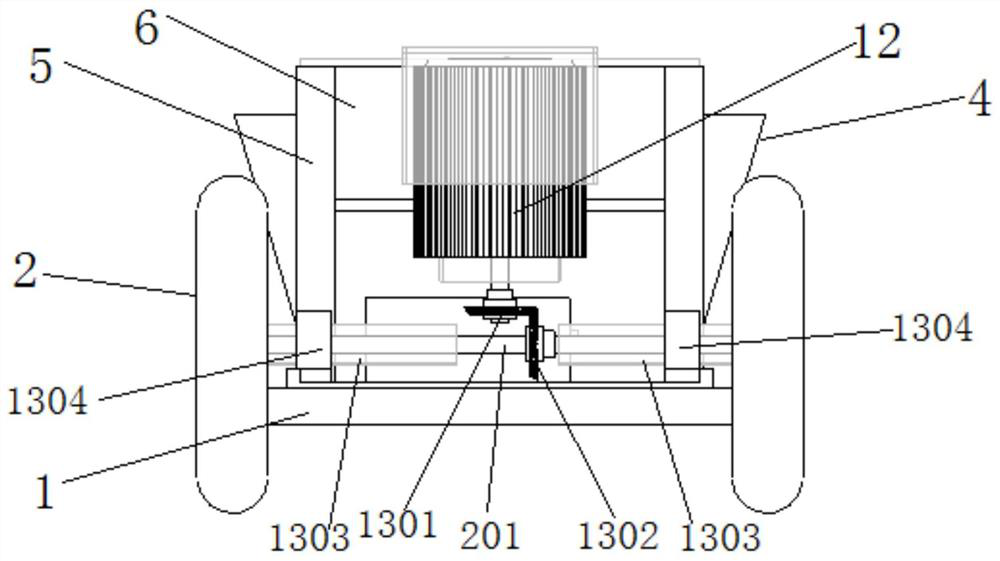

[0044] like figure 1 and figure 2 As shown in the figure, an artificial pipe jacking unearthed trolley includes a vehicle body carrier 1, two sides of the vehicle body carrier 1 are respectively provided with driving wheels 2 and driven wheels 3, and the vehicle body carrier 1 is provided with goods Bucket 4, a control box 6 is also installed on the vehicle body carrier 1 through several main brackets 5, and the control box 6 is provided with a PLC controller 7, a communication module 8 and an electric control module 9 that are electrically connected to each other; A drive motor 12 is installed on the outer side wall of the control box 6 through the motor mounting plate 11, the output end of the drive motor 12 is connected to the axle 201 of the driving wheel 2 through the transmission device 13, and the drive motor 12 is electrically connected to the PLC. Controller 7; a battery 10 is also provided below the control box 6, the battery 10 is detachably mounted on the vehicle...

Embodiment 2

[0060] This embodiment provides a structure of the battery snap-fit installation in the first embodiment.

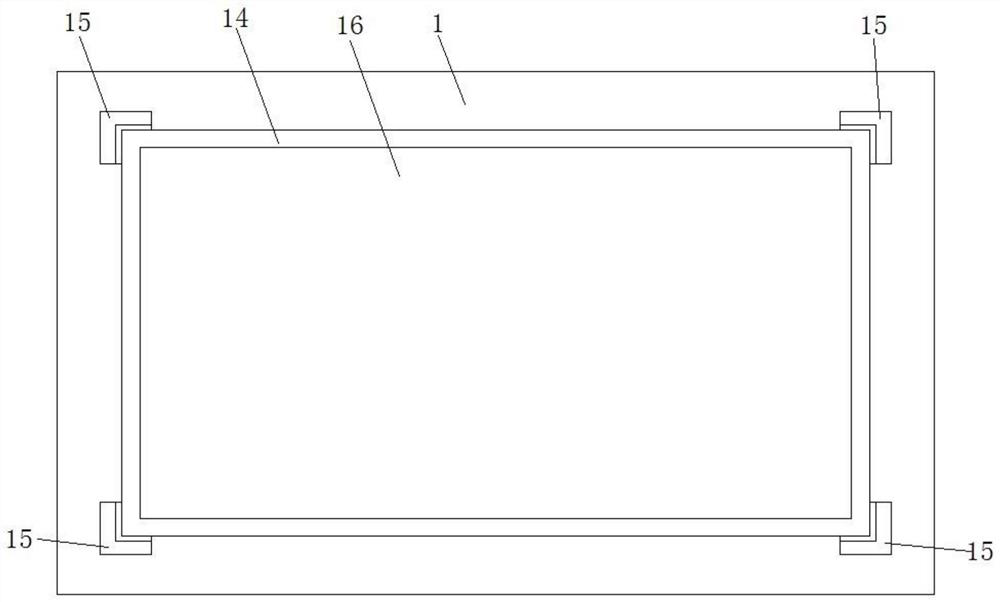

[0061] like Figures 3 to 6As shown, the vehicle body carrier 1 on the inner side of the main bracket 5 is provided with a battery engaging groove 14, and the four corners of the battery engaging groove 14 are respectively provided with vertical guide rods 15. The vertical guide rods The cross-section of 15 is right-angled, and the inner wall of the vertical guide rod 15 is provided with a downwardly inclined angle, so that a guide mechanism is formed in the vertical plane where the four corners of the battery engaging groove 14 are located; The upper four corners of the battery 10 are respectively provided with the engaging pieces 17 , and the engaging pieces 17 all include a connecting plate 1701 , and the connecting plate 1701 is fixed at the right angle of the end of the battery 10 . A number of guide blocks 1702 are arranged between 1701 and the side wall of the ...

Embodiment 3

[0067] This embodiment provides a structure of the protective cover in the first embodiment.

[0068] like Figures 7 to 10 As shown, the protective cover 21 is a baffle that spans across and is plugged on the vehicle body carrier 1 , and several groups of plug connectors 23 are arranged at the bottom of the baffle. There is an insertion slot 24; each group of the insertion pieces includes a straight insertion block 2301 and a trapezoidal gradient wedge 2302 arranged in parallel, and the insertion slot 24 includes a straight slot 2401 and a trapezoidal gradient wedge-shaped slot 2402; the The lateral dimension of the baffle is larger than the lateral dimension of the cargo bucket 4 , and arc plates 22 are respectively provided on both sides of the baffle, and the arc plates 22 are bent toward one side of the cargo bucket 4 .

[0069] Through the insertion of this structure, the disassembly and assembly of the protective cover 21 is convenient, and at the same time, it has bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com