Tank welding equipment

A welding equipment and tank body technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that welding efficiency and welding effect need to be further improved, and the influence of welding slag is large, so as to reduce the effective space area. , The effect of reducing the number of times of downtime to replace the welding rod and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] see Figure 1 to Figure 6 , the present invention provides a kind of technical scheme:

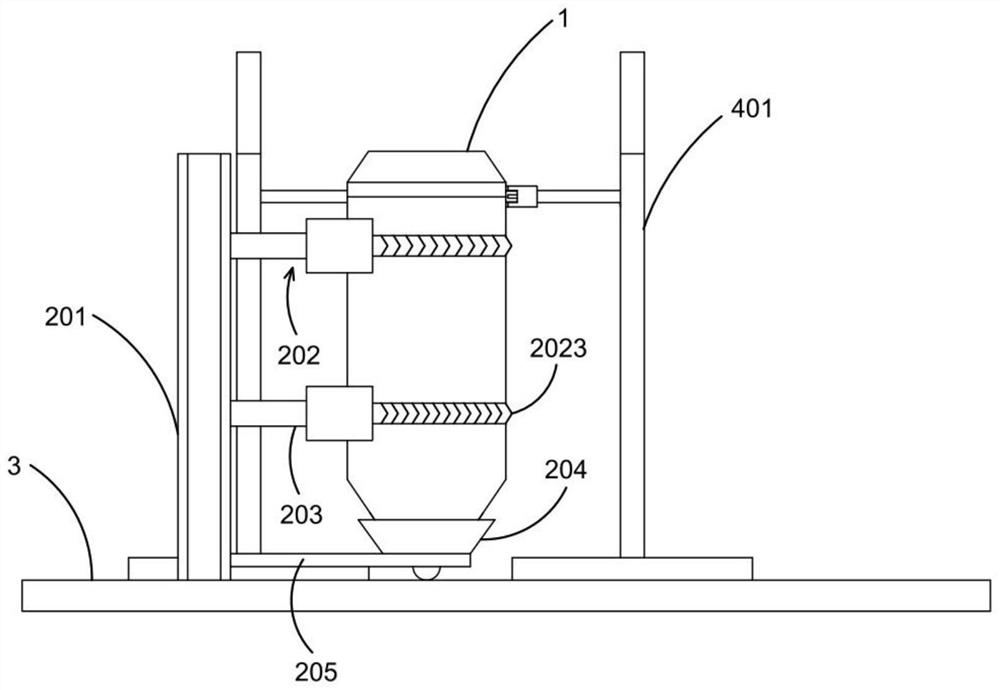

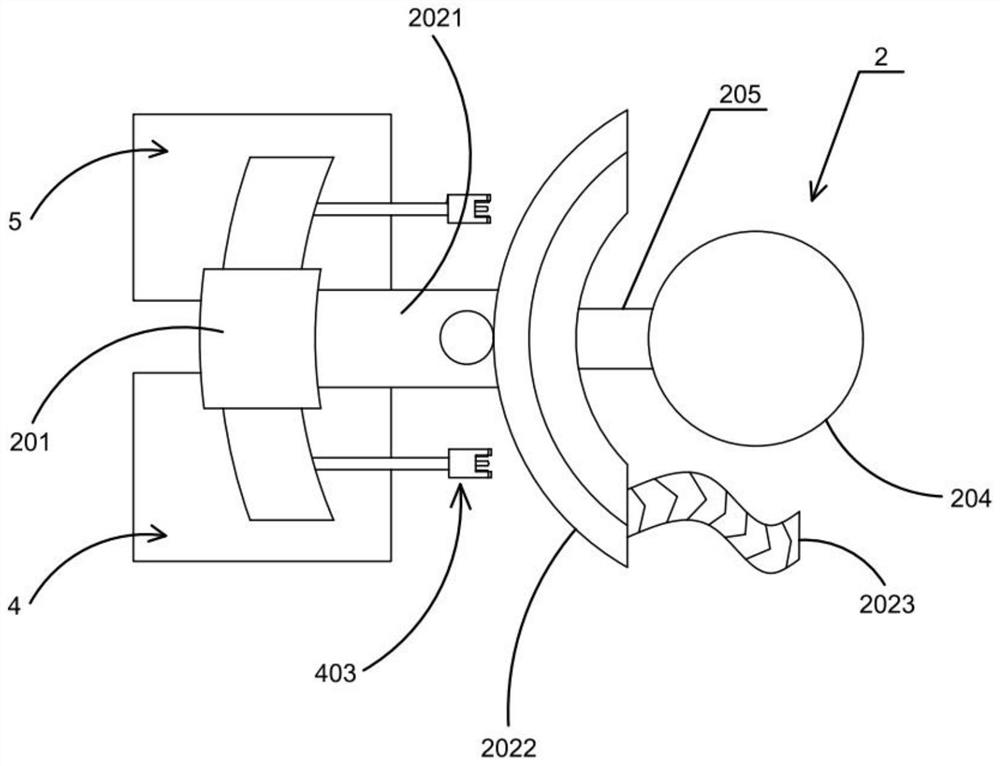

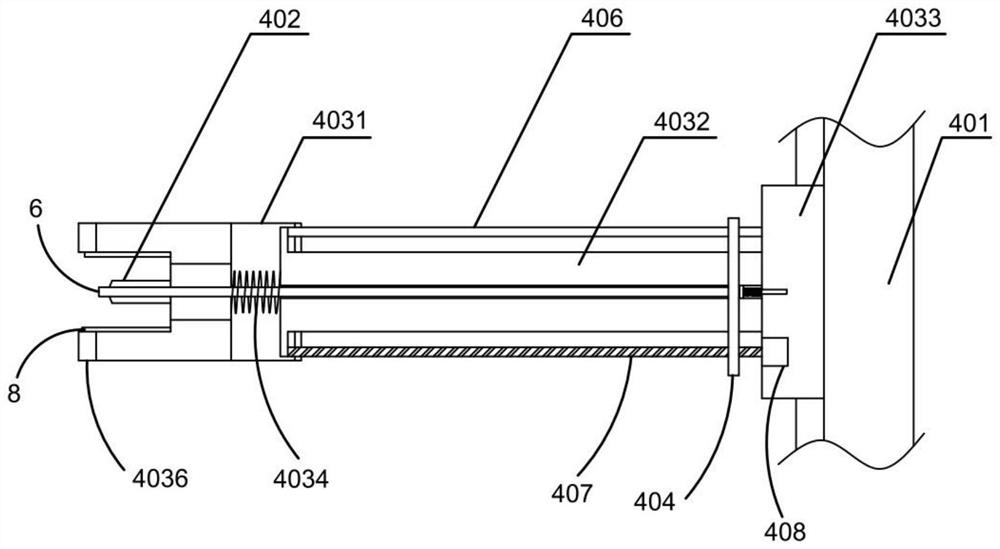

[0025] A tank body welding equipment, including a bearing bracket 2 for supporting the tank body 1 vertically and a welding assembly movably connected with the bearing bracket 2, the bearing bracket 2 includes a limit post 201 fixed on the bearing bottom surface 3 and The first fastening device 202 and the second fastening device 203 are vertically movably arranged on the limiting column 201 . The first fastening device 202 and the second fastening device 203 have the same structure and are located at The lower end is horizontally provided with a carrier plate 204 for placing the tank body 1. The welding assembly includes a first welding device 4 and a second welding device 5 which have the same structure and are movably arranged at both ends of the limiting column 201. The "T"-shaped bearing plate 401 on the bearing bottom surface 3 is provided with a welding head 402 vertically m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com