Brake band for disc of ventilated disc brake

A technology of disc brakes and brake bands, applied in the direction of brake components, brake discs, brake types, etc., can solve problems such as incomplete solutions, avoid blocking or excessively restricting ventilation channels, increase quality, and improve discs The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

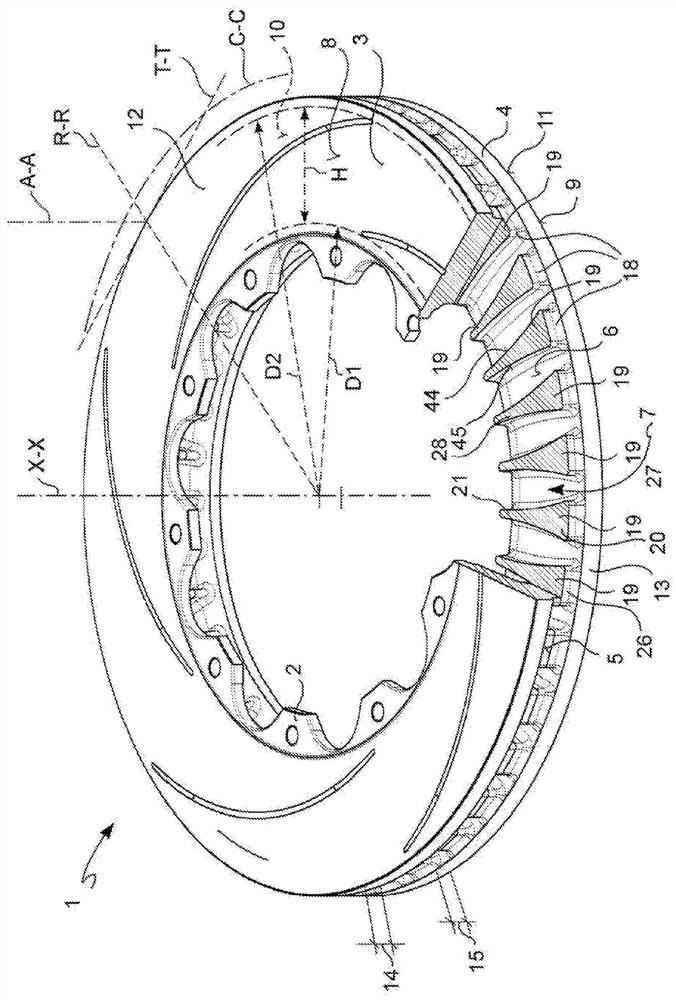

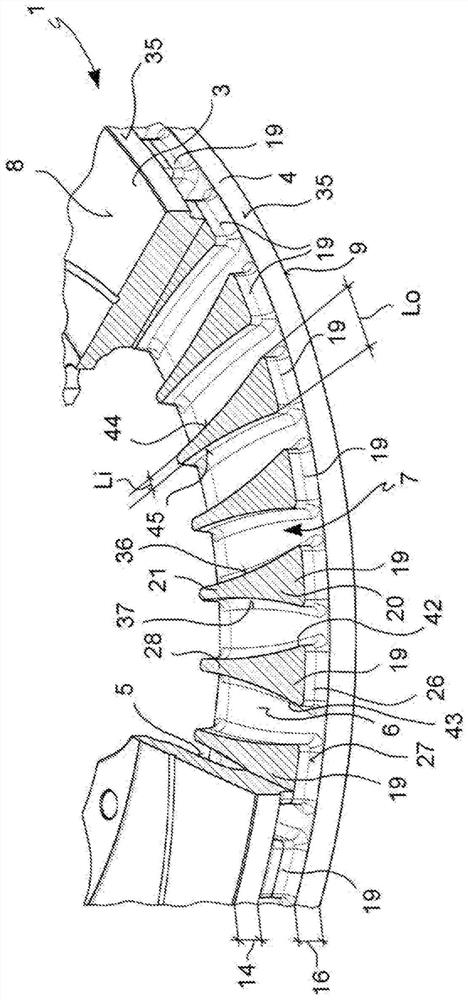

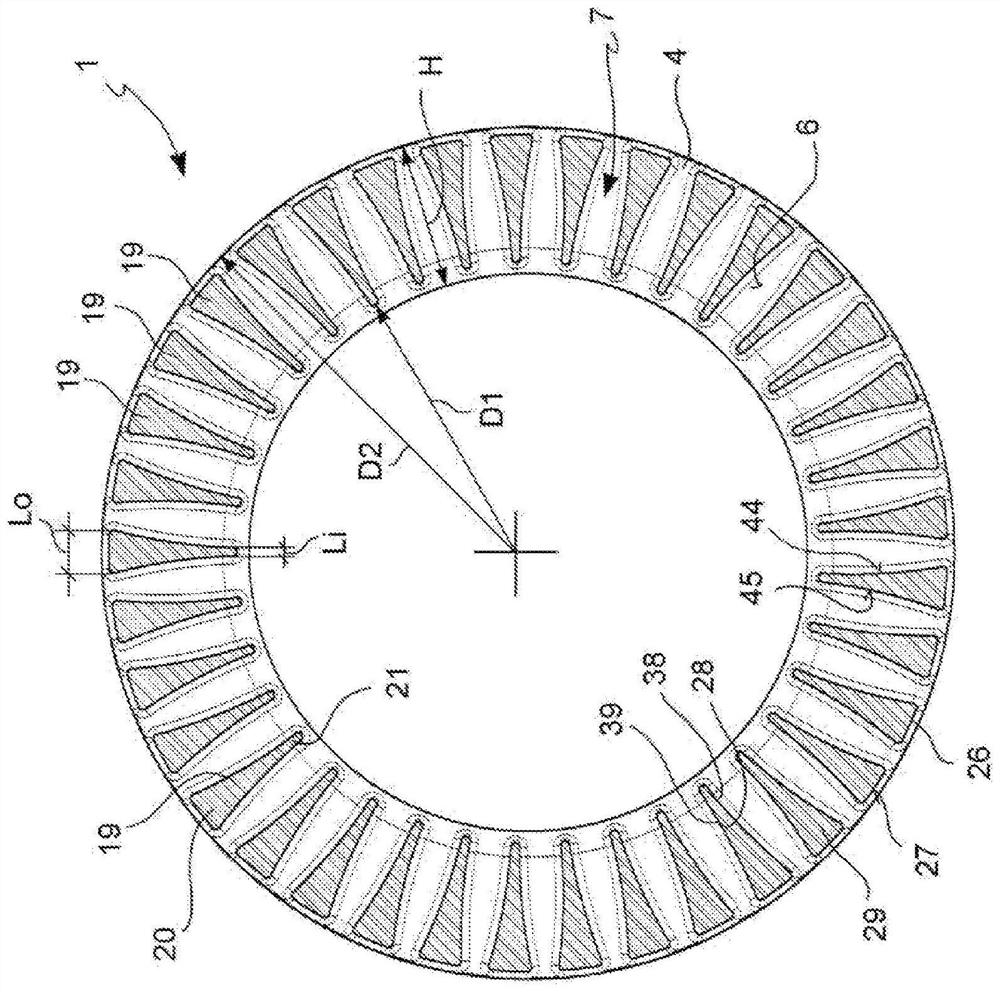

[0063] According to a general embodiment, a brake band 1 for a disc of a ventilated disc brake 2 is provided.

[0064] The brake band 1 extends between an inner diameter portion D1 near the rotational axis X-X of the brake band 1 and an outer diameter portion D2 which is far from the rotational axis X-X. The axis of rotation defines the axial direction X-X.

[0065] Said brake band 1 defines a radial direction R-R, which is substantially orthogonal to said axial direction X-X, and a circumferential direction C-C, which is orthogonal to said axial direction X-X and orthogonal to the radial direction R-R.

[0066] Said brake band 1 comprises two plates 3, 4 facing each other.

[0067] The plate 3 includes an inner surface 5, the plate 4 includes an inner surface 6, which directly or indirectly face each other and delimit a gap 7, which is used for the brake band 1. Ventilation channels are limited.

[0068] The disk 3 includes an outer surface 8 and the disk 4 includes an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com