Linkage air exhaust and supply device of kitchen range hood

A range hood and air supply device technology, which is applied in the field of kitchen utensils, can solve the problems such as the decline of smoke exhaust effect, achieve the effects of improving service life, reducing the growth of bacteria in the kitchen, and ensuring smoke exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

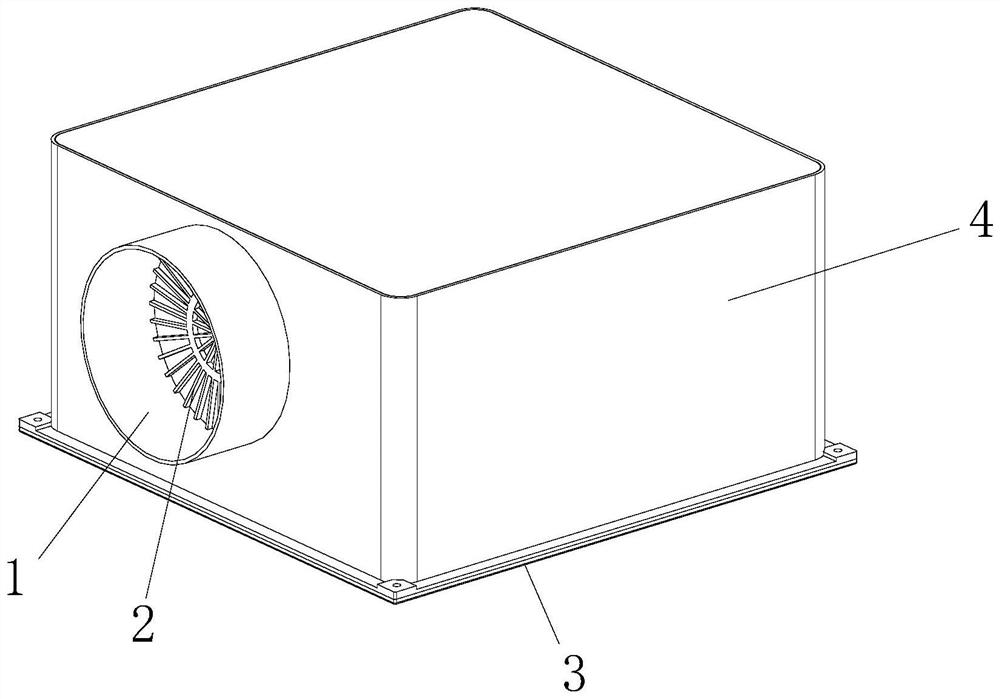

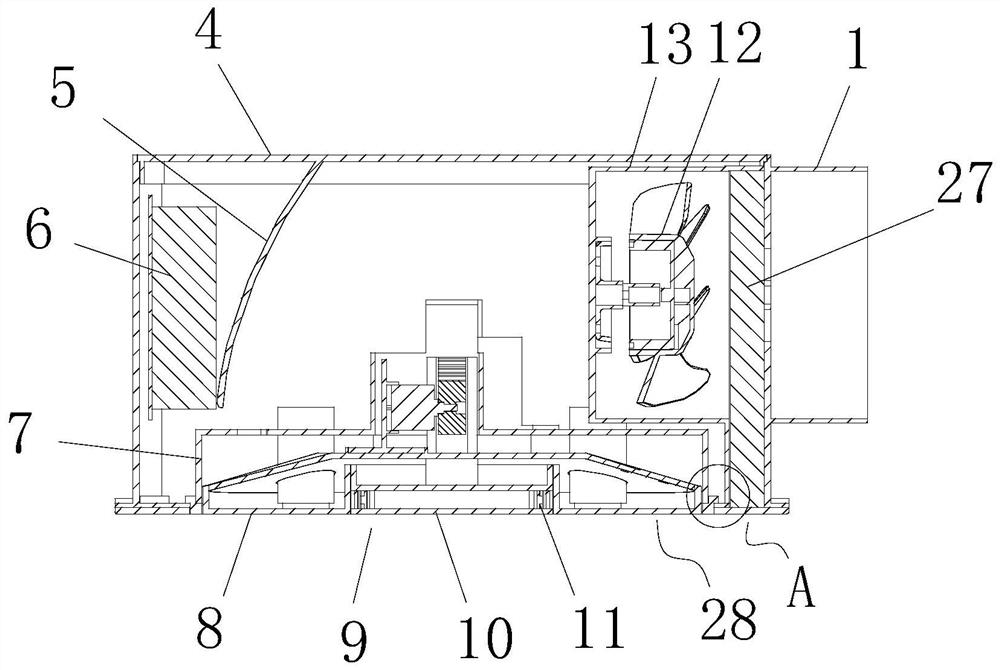

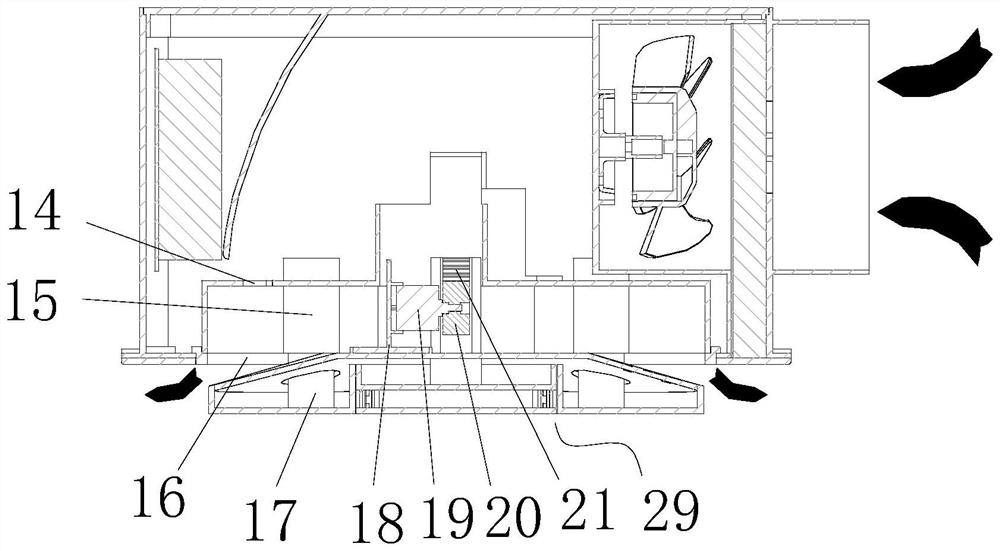

[0033] refer to Figure 1-8 , a kitchen range hood linkage exhaust air supply device, comprising a casing 4, the bottom end face of the casing 4 is integrally provided with a mounting plate 3, one side end face of the casing 4 is integrally provided with an upper air inlet and outlet frame 1, An annular screen frame 2 is installed in the upper inlet and outlet air frame 1, a control circuit board 6 is installed on the inner side wall of the outer casing 4, and an arc baffle 5 is arranged on one side of the control circuit board 6. The arc baffle 5 is fixedly connected to the inner top side wall of the casing 4, the bottom side wall of the casing 4 is integrally provided with an annular frame 7, and the annular frame 7 is installed with a lifting air inlet and outlet assembly 28, and the lifting air inlet and outlet assembly 28 is connected to the annular frame. A lower air inlet and outlet 16 is arranged between the 7, the upper side wall of the annular frame 7 is provided wit...

Embodiment 2

[0047] The difference between this embodiment and the above-mentioned embodiment is that a lifting disinfection assembly 29 is installed at the bottom of the lifting air inlet and outlet assembly 28 , the lifting disinfection assembly 29 includes a disinfection lamp installation frame 10 , and an annular groove is provided on the bottom end surface of the installation frame 8 9. The sterilizing lamp installation frame 10 is arranged in the annular groove 9, a plurality of ultraviolet sterilizing lamps 11 are installed on the outer end of the sterilizing lamp installation frame 10, and the upper end surface of the sterilizing lamp installation frame 10 is fixedly connected with a second lamp. Rack plate 21, a motor mounting seat 18 is fixed on the upper end surface of the mounting frame 8, a second motor 19 is mounted on the motor mounting seat 18, and the output end of the second motor 19 is fixedly connected with a second driving gear 20 , the second rack plate 21 is verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com