Auxiliary device for laying power transmission line

A technology for power transmission lines and auxiliary devices, which is applied in the directions of transportation and packaging, thin material handling, and transportation of filamentous materials. Cable crimping and other problems, to avoid the phenomenon of winding and knotting, to facilitate lifting and transportation, and to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

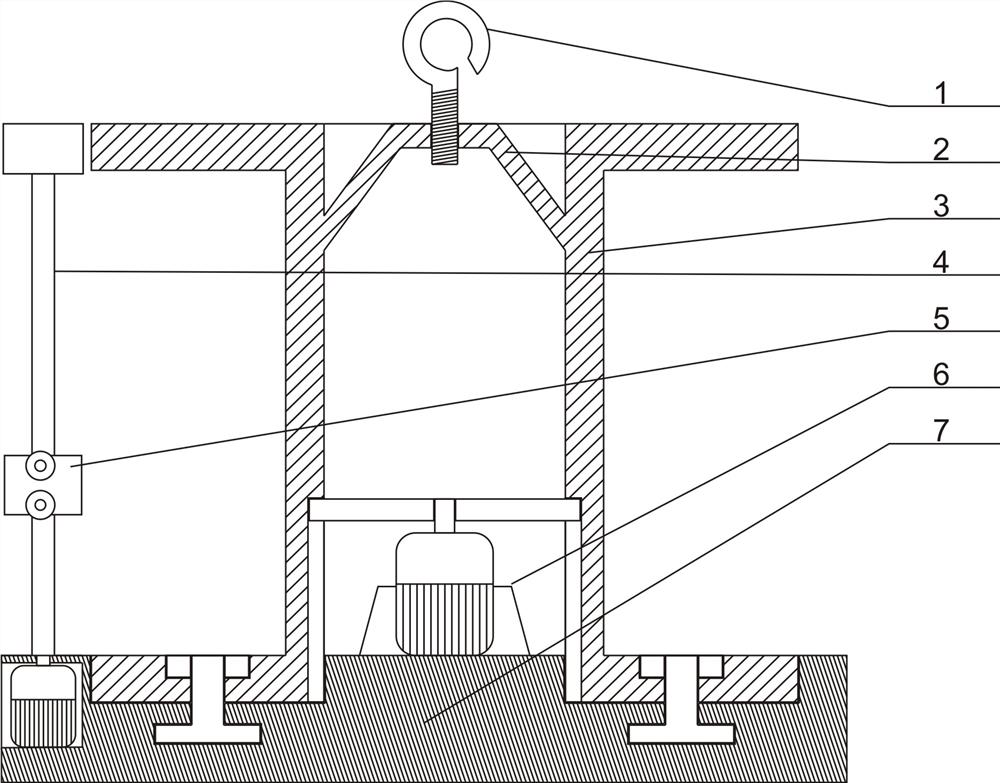

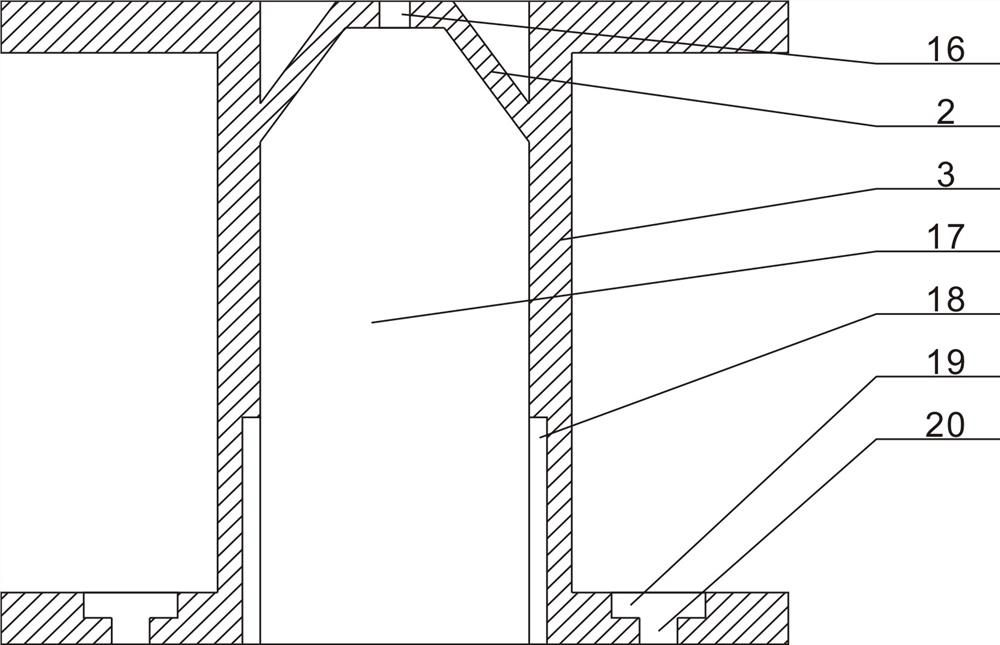

[0039]Embodiment 1, an auxiliary device for laying power transmission lines, including a base 7 and a cable reel 3, the upper surface of the base 7 is provided with an annular groove 12, and several inner bottom surfaces of the annular groove 12 are evenly distributed to support the cable reel 3, And realize the rolling member 13 that the cable reel 3 rotates, the rolling member 13 is a universal ball or a rolling shaft that is consistent with the direction of rotation of the cable reel 3, and the vertically placed cable reel 3 is placed in the annular groove 12 on the base 7 , the middle part of the vertically placed cable reel 3 forms a columnar inner cavity 17, the upper and lower ends of the columnar inner cavity 17 are open structures, the upper part of the columnar inner cavity 17 is provided with a lifting frame 2, and the upper part of the lifting frame 2 is provided with mounting screw holes 16, The hook 1 is threadedly connected with the mounting screw hole 16. Throug...

Embodiment 2

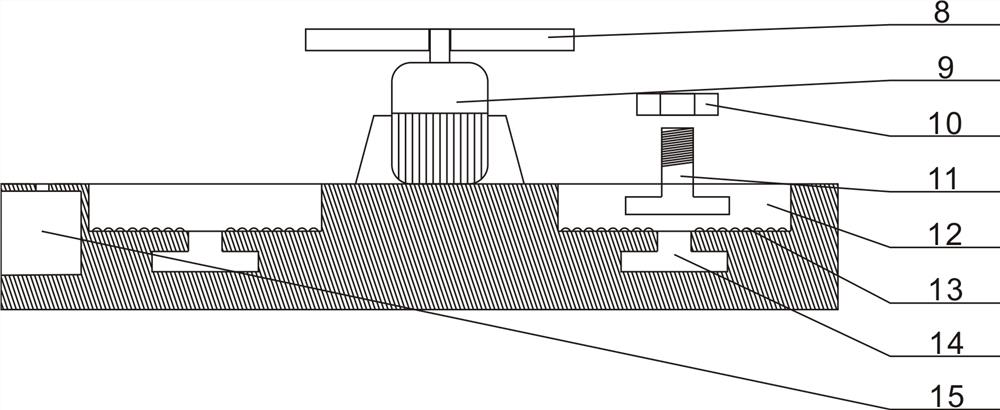

[0043] Embodiment 2, for the winding or unwinding operation of a large-diameter cable, due to its heavy mass, the inertia of the cable reel 3 during the rotation is relatively large. The inner bottom surface of the annular groove 12 is provided with a bottom annular groove 14. The cross section of the bottom annular groove 14 is an inverted T-shaped structure. The bottom annular groove 14 is provided with a bolt 11 that slides along the bottom annular groove 14. The vertically placed The bottom side plate of the cable reel 3 is provided with a limit hole 20 that is compatible with the bolt 11. The head of the bolt 11 penetrates the limit hole 20 and is fixed by a nut 10. In order to ensure the flatness of the bottom side plate of the cable reel 3 A sinking groove 19 is provided on the bottom side plate of the cable tray 3 , and the limiting hole 20 is arranged on the inner bottom surface of the sinking groove 19 .

Embodiment 3

[0044] Embodiment 3, since the cables on the cable reel 3 are helically reciprocated, the cable combing mechanism 5 also needs to carry out reciprocating lifting motions. Automatic lifting drive, the upper end of the vertical rod 4 is provided with a top plate 21, the upper end of the screw rod 23 is rotationally connected with the lower surface of the top plate 21, and the lower surface of the top plate 21 and the upper surface of the base are provided with a position for a touch-sensitive movable block 28, and the drive motor is controlled 24 Reversely rotating limit switch 22; when the cable combing mechanism 5 slides up to the top along the vertical bar 4, the movable block 28 conflicts with the limit switch 22 on the lower surface of the top plate 21, and the limit switch 22 receives the pressing signal Afterwards, the driving motor 24 is controlled to reverse, and the cable combing mechanism 5 slides downward through the lifting adjustment mechanism, touches the bottom li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com