Mobile new energy automobile charging pile

A new energy vehicle and charging pile technology, applied in electric vehicles, charging stations, vehicle parts, etc., can solve the problems of charging cable damage, charging cable winding, knotting, reducing service life, etc., to increase service life, Avoid the effect of slipping out and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

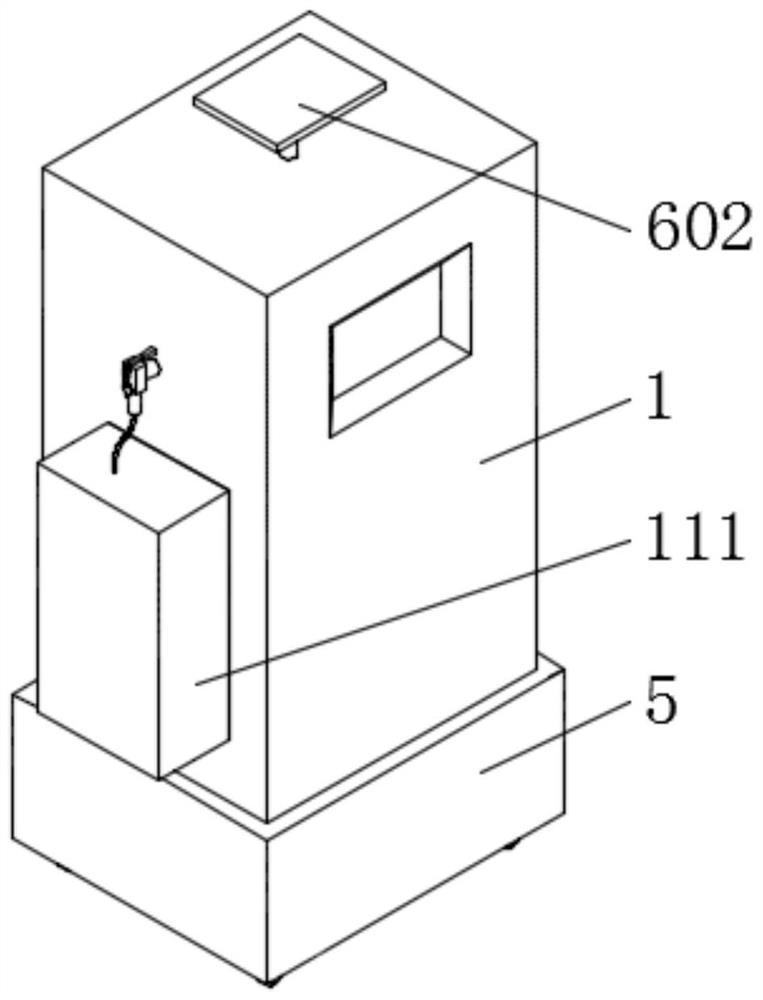

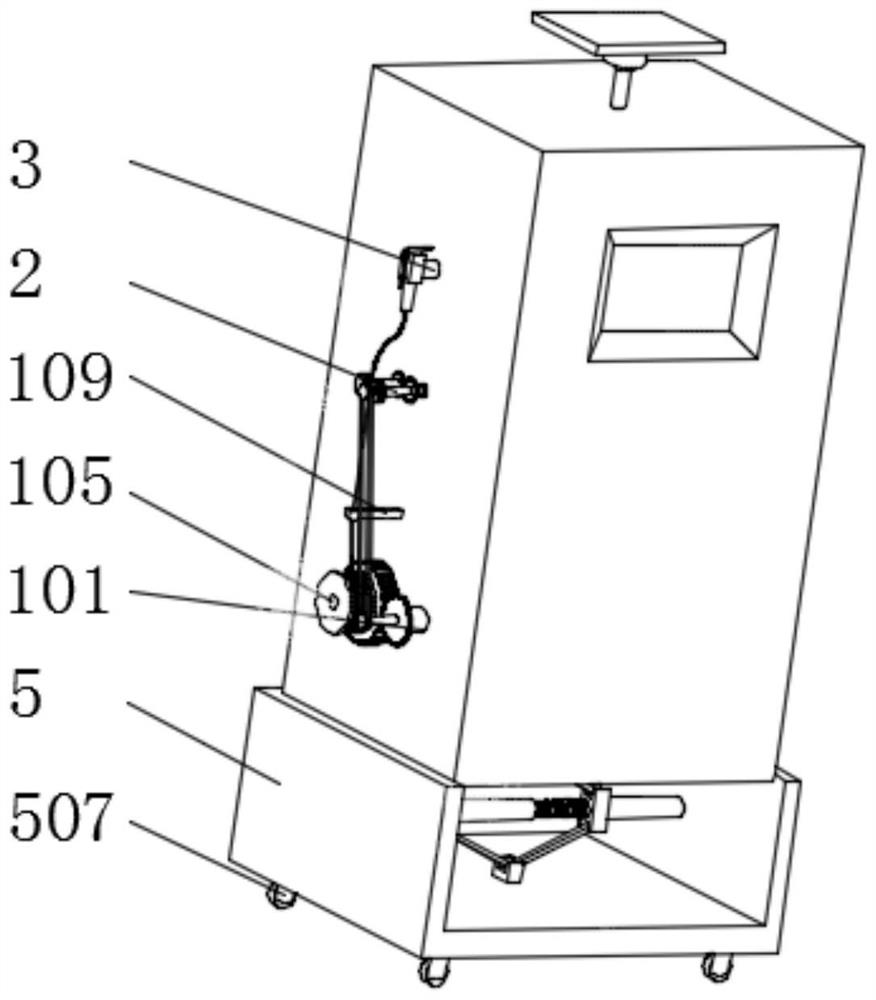

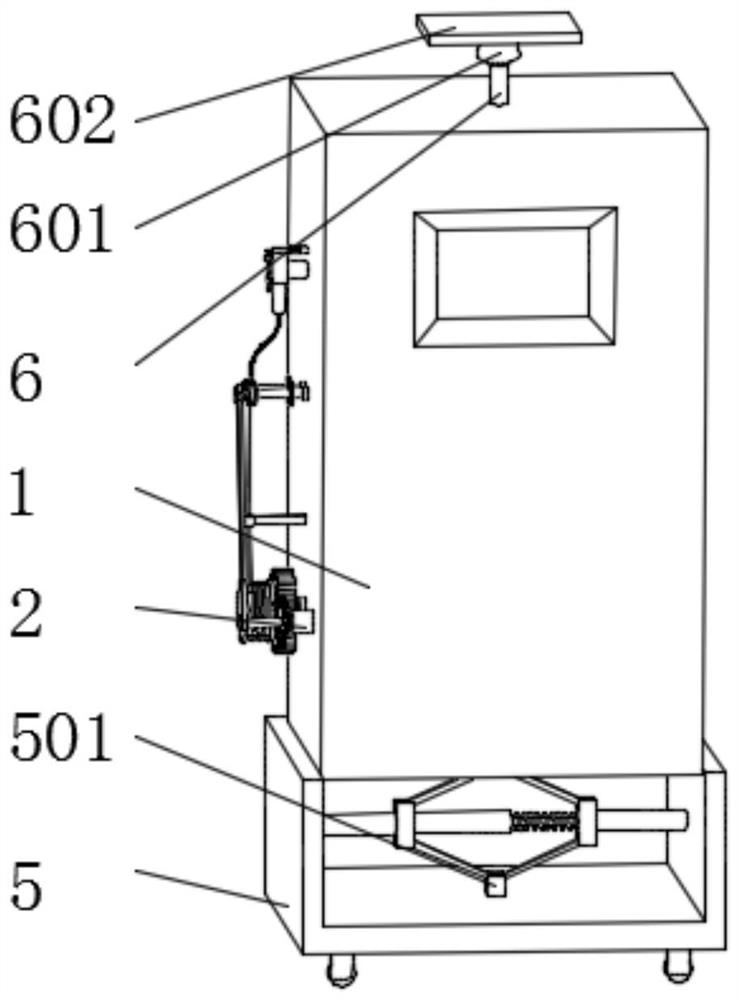

[0042] Example: Reference Figure 1-9 The shown mobile new energy vehicle charging pile includes a charging pile body 1, and the charging pile body 1 can be any metal new energy charging pile in the prior art.

[0043] A base 5 is installed on the charging pile body 1 in a movable socket, and universal wheels 507 are fixedly installed around the bottom of the base 5. One side of the charging pile body 1 is installed with a retractable conveying part, and the bottom of the charging pile body 1 is provided with a The shock absorber assembly, the retractable conveying part includes a retractable assembly and a conveying assembly, the retractable assembly includes a servo motor 101 fixedly installed on one side of the charging pile body 1, and the output end of the servo motor 101 is fixedly installed with a rotating shaft 102 through a coupling One end of the rotating shaft 102 is fixedly installed with a drive gear 103, one side of the charging pile body 1 is rotatably installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com