Pneumatic intelligent feeding equipment of spring grinder

A spring grinding machine, intelligent technology, applied in the direction of grinding/polishing equipment, grinding feed movement, metal processing equipment, etc., can solve the problems of spring winding and affecting the feeding efficiency, so as to reduce the false detection rate and ensure high efficiency Feeding performance, the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

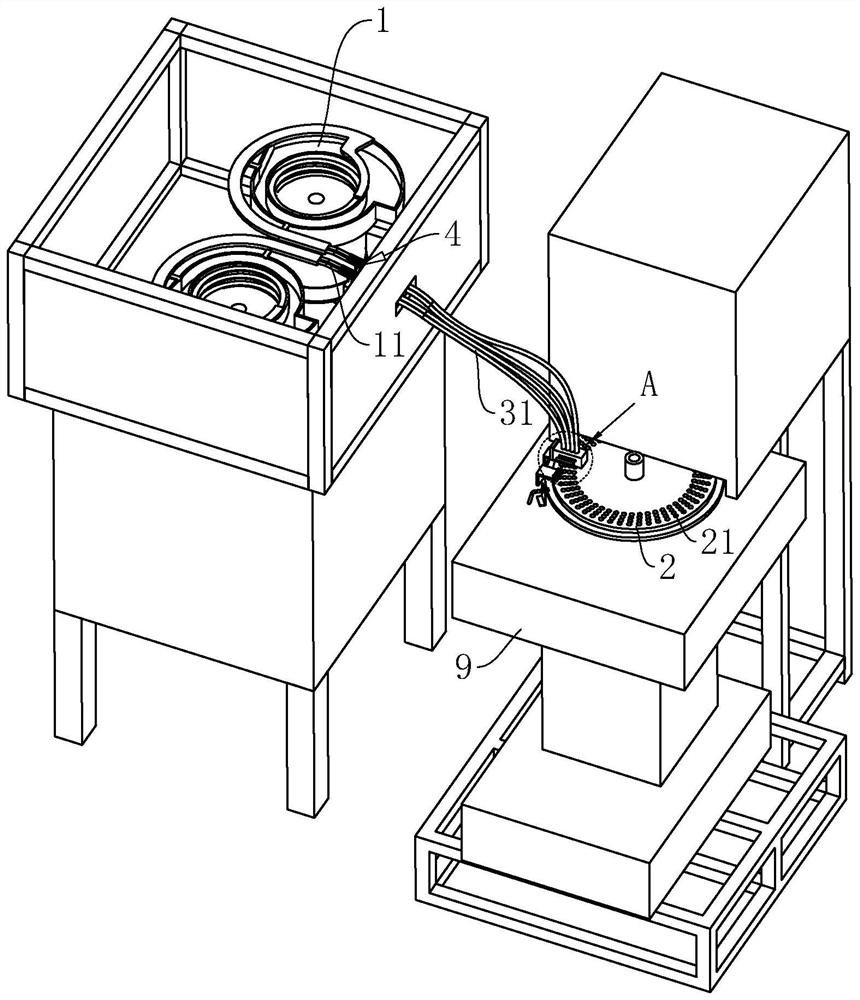

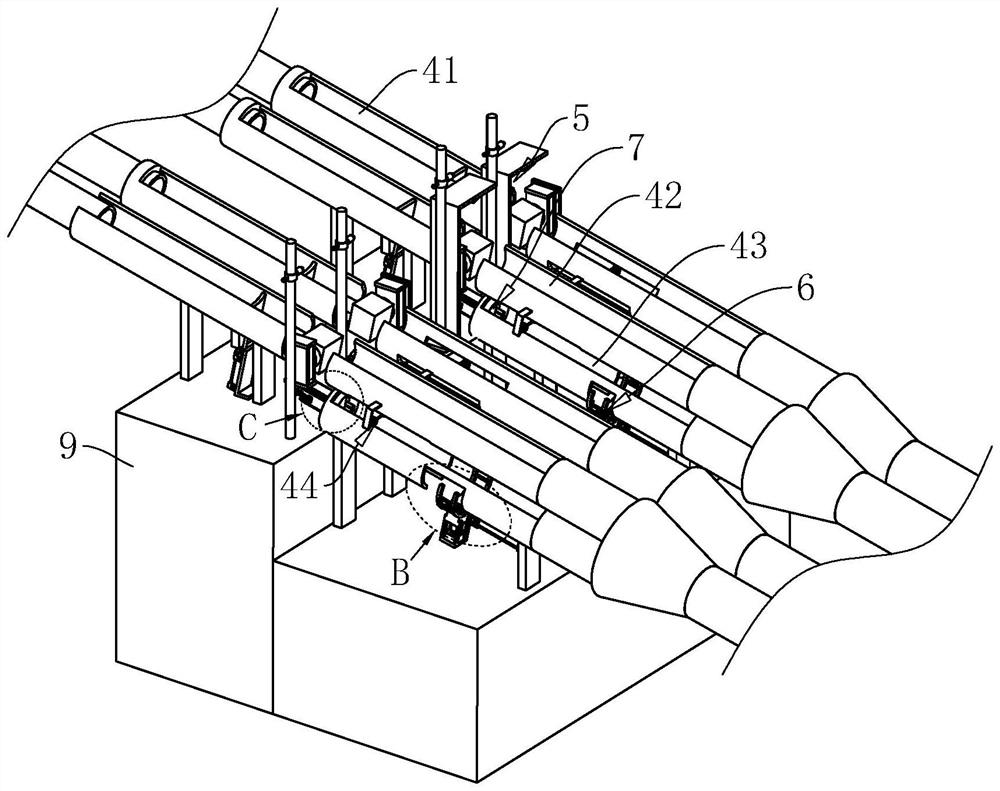

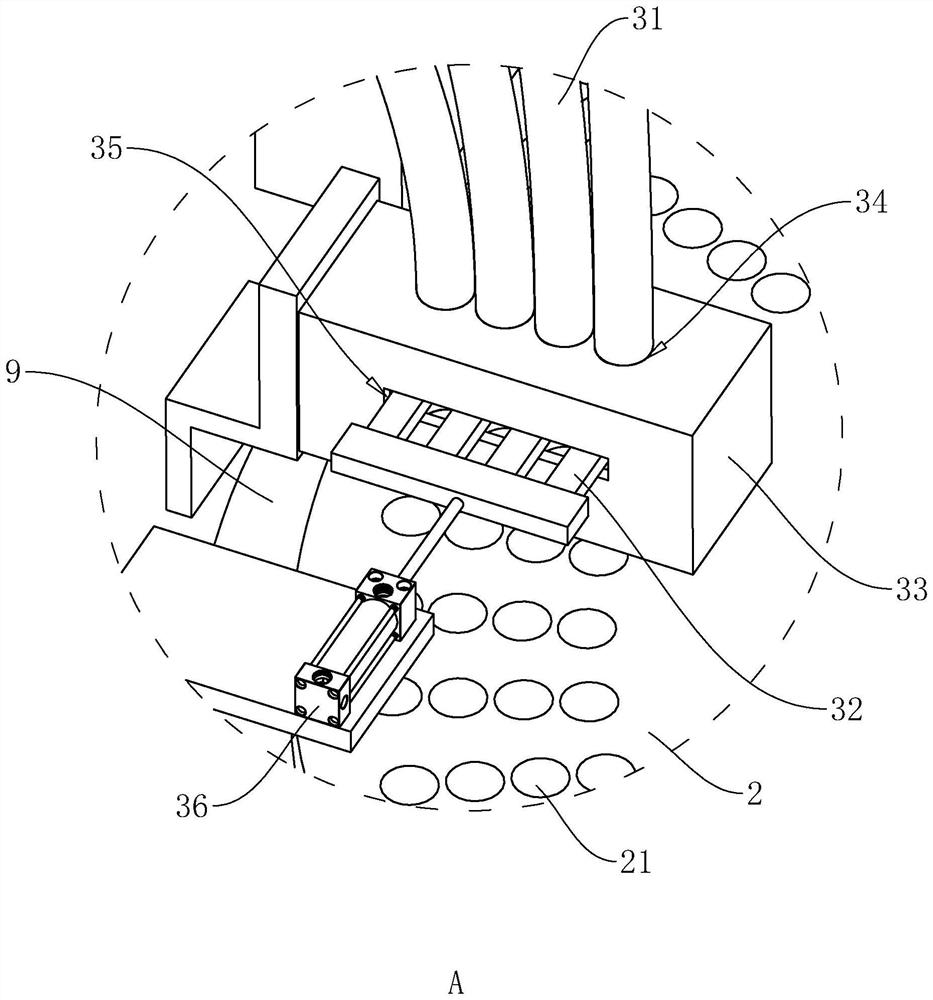

[0064] The embodiment of the present application discloses a pneumatic intelligent feeding device for a spring grinding machine. refer to figure 1 and figure 2 The pneumatic intelligent feeding equipment of the spring grinding machine includes a machine table 9, a vibration plate 1, a guide groove 11, a material plate 2 and a mold sleeve 21. The material plate 2 is rotated and arranged on the machine table 9, and a plurality of In the die hole where the die sleeve 21 is placed; the guide groove 11 is connected with a material guide tube 31 whose one end points to the upper die sleeve 21 of the material tray 2, and the end of the material guide pipe 31 close to the material tray 2 is provided with a card plate 32 for outputting springs one by one, A detection channel 4 is connected between the guide groove 11 and the material guide tube 31, and the detection channel 4 is provided with:

[0065] A detection device 5 is used to detect whether two adjacent springs are wound;

...

Embodiment 2

[0105] The embodiment of the present application discloses a pneumatic intelligent feeding device for a spring grinding machine. refer to Figure 7 , the difference from the first embodiment is that the positioning structure is set as a positioning groove 5132 opened on the flip seat 511 , and the groove depth of the positioning groove 5132 is not less than one third of the length of the spring.

Embodiment 3

[0107] The embodiment of the present application discloses a pneumatic intelligent feeding device for a spring grinding machine. refer to Figure 8 , and the difference from the first embodiment is: the positioning structure is set as the electromagnet 5133 embedded in the flip seat 511, when the spring output from the guide slot 11 collides with the flip seat 511, the electromagnet 5133 is energized to adsorb the spring; When the flip seat 511 drives the spring to flip to the side of the detection channel 4 close to the material guide tube 31 , the electromagnet 5133 is powered off, and the spring can slide freely in the detection channel 4 . Of course, the premise that this embodiment can be implemented is limited to the feeding of ferromagnetic springs such as carbon steel springs, but this solution has the best effect of stabilizing the springs during the overturning process.

[0108] And it can be further improved. For example, in other feasible embodiments, protrusions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com