Odor-free total-effect interior wall paint and preparation method thereof

A technology for interior wall paint and deodorization, which is applied in the field of latex paint, can solve the problems of long drying time, difficulty in brushing and heavy taste, etc., and achieves the effect of removing carcinogenic toxins, excellent deodorization effect, and improving comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Pure taste full effect interior wall paint, raw materials by weight percentage, deionized water 19%-21%, pigments and fillers 35%-37%, emulsion 30%-32%, film-forming agent 7.2%-7.3%, fungicide 0.3% -0.4%, cellulose 0.6%-0.7%, defoamer 0.6%-0.7%, dispersant 0.8%-1%, auxiliary 3.15%-3.25%. The raw material components are all commercially available products.

[0033] The emulsion is a modified acrylic core-shell emulsion.

[0034] The bactericide is a nano anion composite bactericide.

[0035] The auxiliary agent is a new type of azo initiator, dimethyl azobisisobutyrate.

[0036] The pigment and filler is kaolin.

[0037] The preparation method of net taste full effect interior wall paint, it comprises the following steps:

[0038] 1) Weigh the cellulose according to the above formula, add deionized water and place one piece in a stirring tank, and cool down to room temperature after 1-2h of high-speed stirring to completely dissolve the cellulose particles;

[0039]...

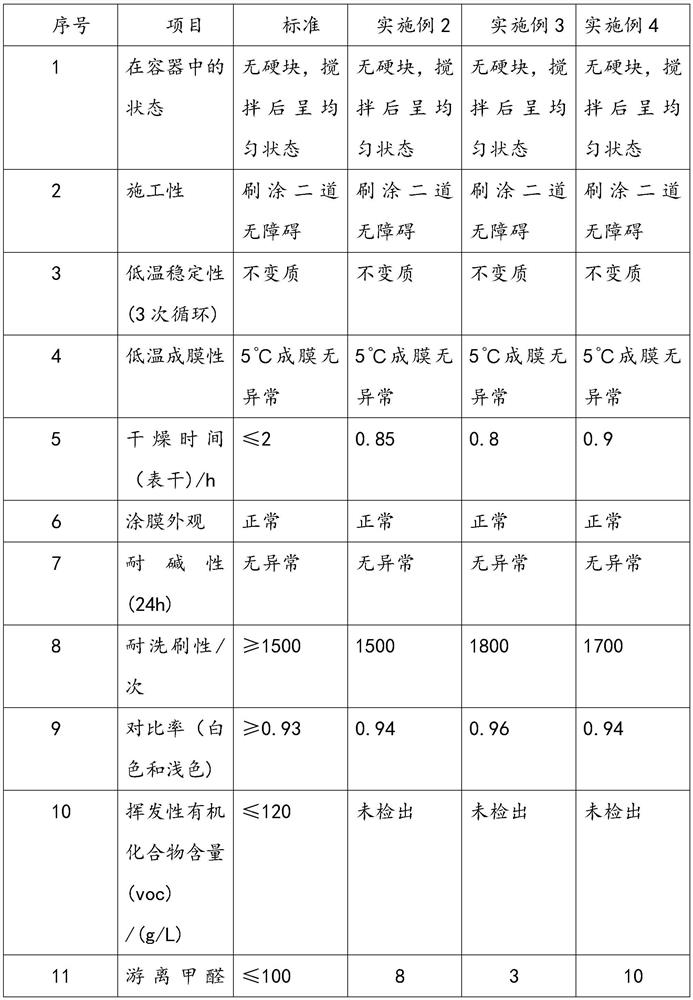

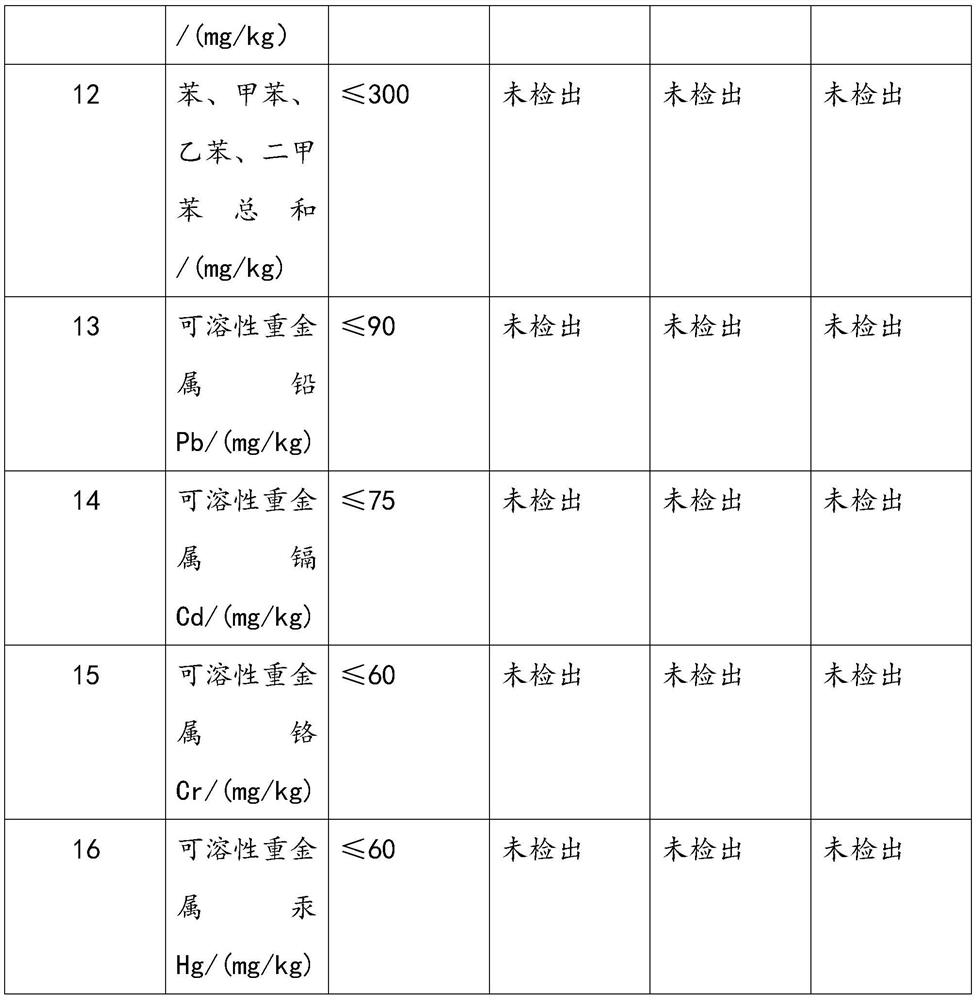

Embodiment 2

[0045] Pure taste full effect interior wall paint, raw materials by weight percentage, deionized water 19%, pigments and fillers 36%, modified acrylic core-shell emulsion 32%, film-forming agent 7.2%, nano-anion composite bactericide 0.3%, cellulose 0.65% %, defoamer 0.7%, dispersant 1%, auxiliary agent (new azo initiator dimethyl azobisisobutyrate) 3.15%. Its preparation method comprises the following steps:

[0046] 1) Weigh cellulose, add deionized water, and place one piece in a stirring tank, and after 2 hours of high-speed stirring, the cellulose particles are completely dissolved and then cooled to room temperature;

[0047] 2) Add the dispersant and defoamer in the formula amount into the stirring tank, carry out dispersion stirring at 800r / min, stir for 25min, and then heat to 36°C;

[0048] 3) Weigh the pigments, fillers and additives according to the formula amount, add them to the mixture in the previous step, stir at 800 r / min, and stir for 25 min;

[0049] 4) W...

Embodiment 3

[0053] Pure taste full-effect interior wall paint, raw materials by weight percentage, deionized water 20%, pigments and fillers 37%, modified acrylic core-shell emulsion 30%, film-forming agent 7.25%, nano-anion composite bactericide 0.35%, cellulose 0.7% %, defoamer 0.6%, dispersant 0.9%, auxiliary agent (new azo initiator dimethyl azobisisobutyrate) 3.2%. Its preparation method comprises the following steps:

[0054] 1) Weigh the cellulose, add deionized water, and place one piece in a stirring tank. After 1.5h of high-speed stirring, the cellulose particles are completely dissolved and then cooled to room temperature;

[0055] 2) Add the dispersant and defoamer of the formula amount into the stirring tank, carry out dispersion stirring at 900r / min, stir for 25min, and then heat to 40°C;

[0056] 3) Weigh pigments, fillers and auxiliary agents according to the formula amount, add them to the mixture in the previous step, stir at 900 r / min, and stir for 25 min;

[0057] 4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com