Concrete taking waste glass as aggregate and preparation process thereof

A waste glass and concrete technology, which is applied in the field of concrete with waste glass as aggregate and its preparation process, can solve the problems of waste glass composition complexity, space occupation, environmental pollution, etc., and achieve enhanced chloride ion diffusion resistance and huge economical benefit, durability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

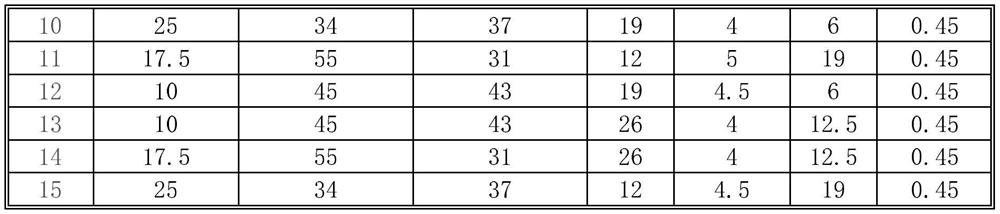

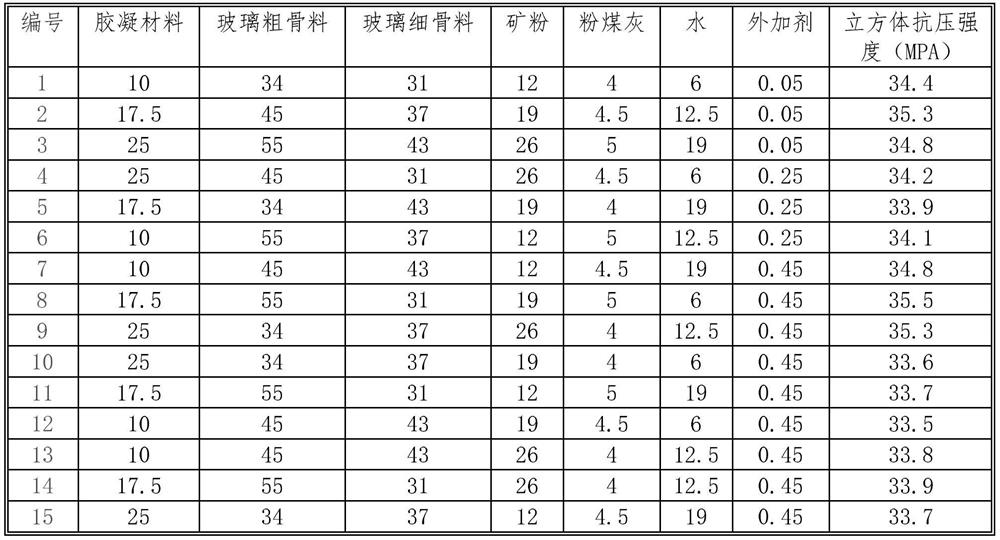

Examples

Embodiment approach

[0104] The present embodiment also discloses a typical embodiment of the concrete with waste glass as aggregate, a concrete preparation process capable of preparing the waste glass as aggregated as described in any of the above embodiments, the prepared glass coarse aggregate, glass fine aggregate, mineral powder, fly ash, cement, glass micronized powder, silica ash in accordance with the number of mass ingredients after the completion of the pre-mixing 20-60s, to obtain primary materials; The admixture and water corresponding to the above overall rubber mass ratio are added to the primary material in the mixer, stirring more than 160s; That is, the finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com