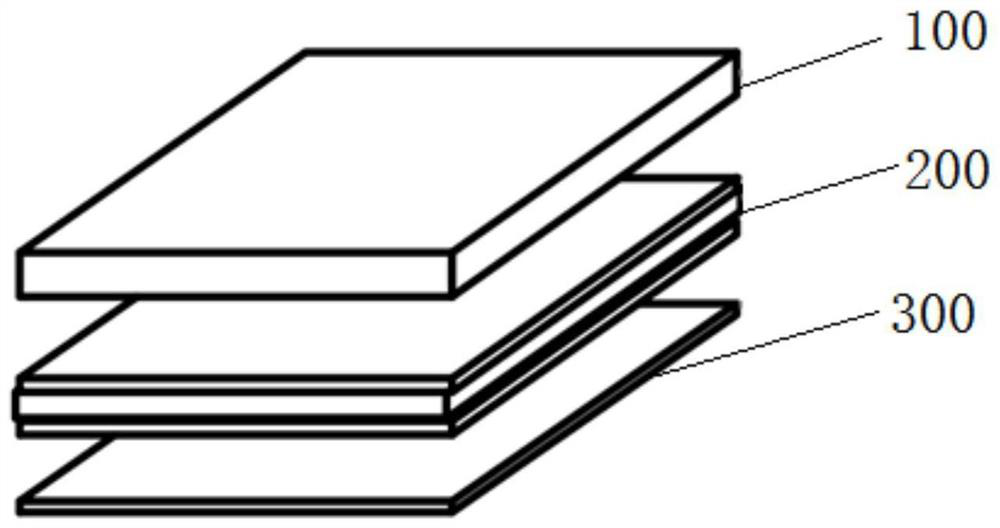

Composite floor and preparation method thereof

A composite floor and bonding technology, which is applied in the direction of construction, floor, building structure, etc., can solve the problems of increasing construction consumables and decoration costs, and achieve the effect of reducing decoration costs and construction consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In another embodiment, a preparation method of a laminate floor, comprising the steps of:

[0044] S1. Fill the grooves of the marble layer;

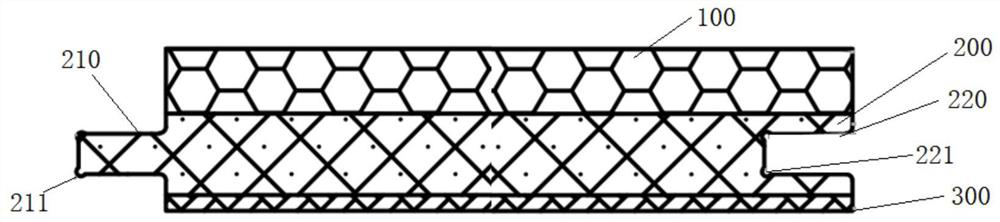

[0045] S2. Paste the SPC substrate layer and the EVA foam layer through polyurethane AB glue;

[0046] S3. A first clamping portion is arranged at one end of the SPC base material layer, and a second clamping portion is arranged at the other end of the SPC base material layer;

[0047] S4. Laminate the SPC substrate layer with the filled marble layer through hot melt adhesive;

[0048] S5, through the fitting connection between the first clamping portion and the second clamping portion, the multiple SPC base material layers are clamped, and then the multiple marble layers are connected. In the preparation process, the cold pressing time is 2h, the pressure is 6mpa, and the curing time is 24h to obtain the finished product.

[0049] Specifically, S1, the step of filling the groove of the marble layer includes:

[0050] S11. Fi...

Embodiment 1

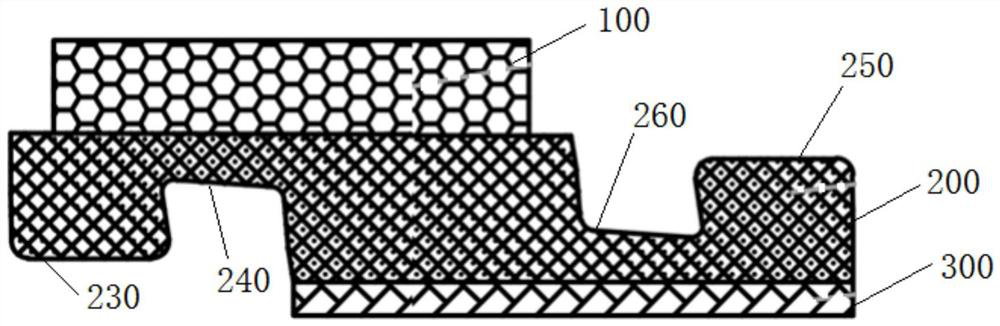

[0058] 1. The back groove of the marble layer is specially treated. Marble with a thickness of 2mm is selected. First, the back of the marble layer is filled with putty powder. The thickness of the filling is to fill the back groove of the marble layer 2mm higher than the plane. Then carry out water-based paint treatment on the surface of the marble layer, the thickness of the water-based paint is 15g / m 2 . Finally, a special acrylic is applied on the surface of the water-based paint (the acrylic paint is a water-based paint).

[0059] 2. The SPC base material layer with a thickness of 4mm is subjected to a flat buckle treatment. The SPC base material layer is provided with a first tenon and a first groove. The first tenon is in the shape of a long strip along the SPC base material layer. There are convex arcs on the top and bottom of the tenon, and the corresponding arc is 30°. The length of the first tenon (referring to the distance between the outer end of the first tenon...

Embodiment 2

[0064] 1. The back groove of the marble layer is specially treated. The marble layer with a thickness of 3mm is selected. First, the back of the marble layer is filled with putty powder, and the filling thickness is to fill the back groove of the marble layer 2mm higher than the plane. Then carry out water-based paint treatment on the surface of the marble layer, the thickness of the water-based paint is 15g / m 2 ; Finally, apply special acrylic on the surface of the water-based paint (the acrylic paint is a water-based paint).

[0065] 2. The SPC base material layer with a thickness of 6 mm is subjected to a flat buckle treatment. The SPC base material layer is provided with a first tenon and a first groove. The first tenon is in a strip shape along the SPC base material layer. There are convex arcs on the top and bottom of the tenon, and the corresponding arc is 30°. The length of the first tenon (referring to the distance between the outer end of the first tenon and the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com