Condensation collecting device

A condensation and collection system technology, applied in fertilization devices, applications, organic fertilizers, etc., can solve the problems of increased energy consumption in sludge plants, increased ventilation, and affecting the heat balance of the pile, so as to save construction materials and costs , save operating costs, reduce the height of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

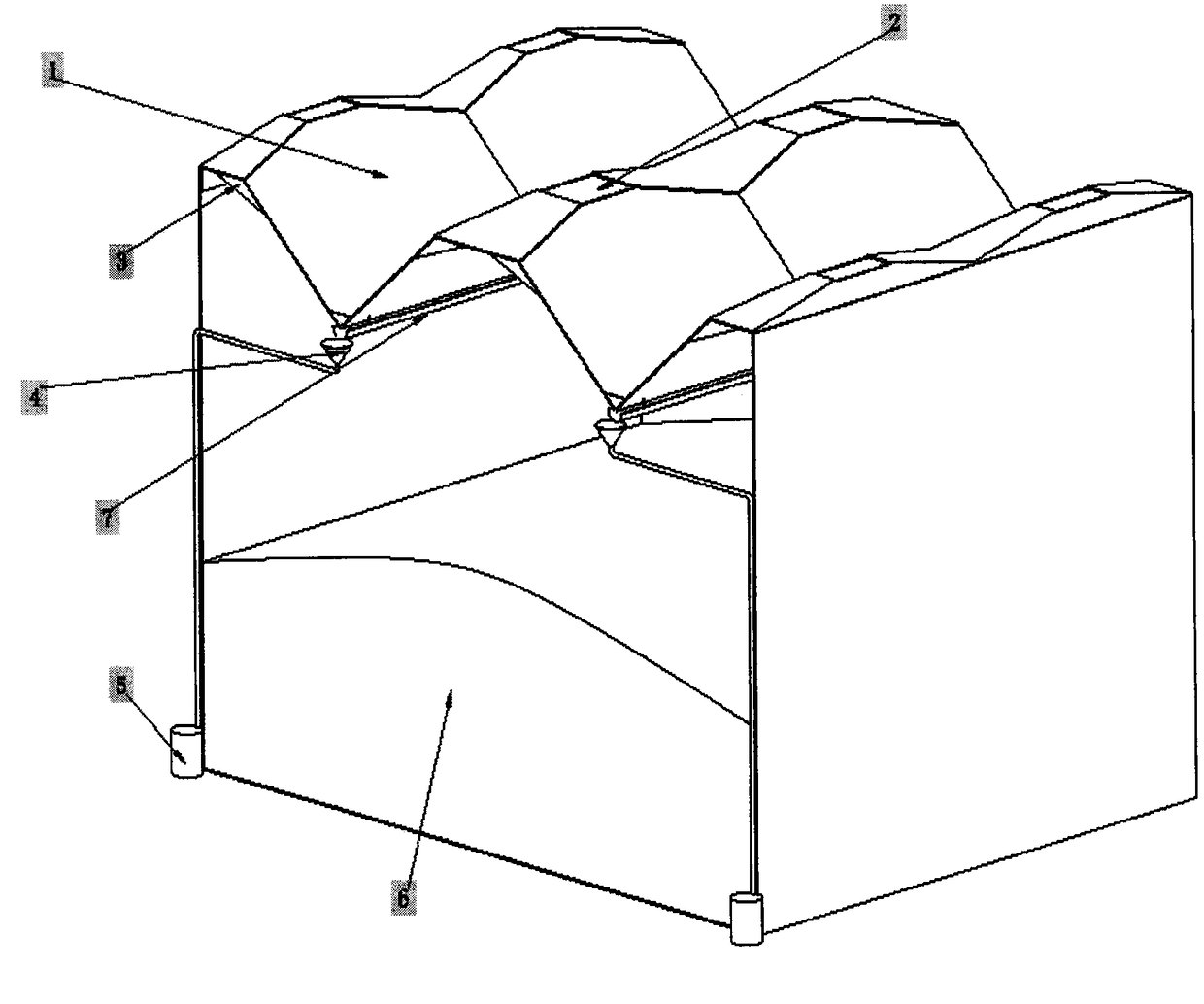

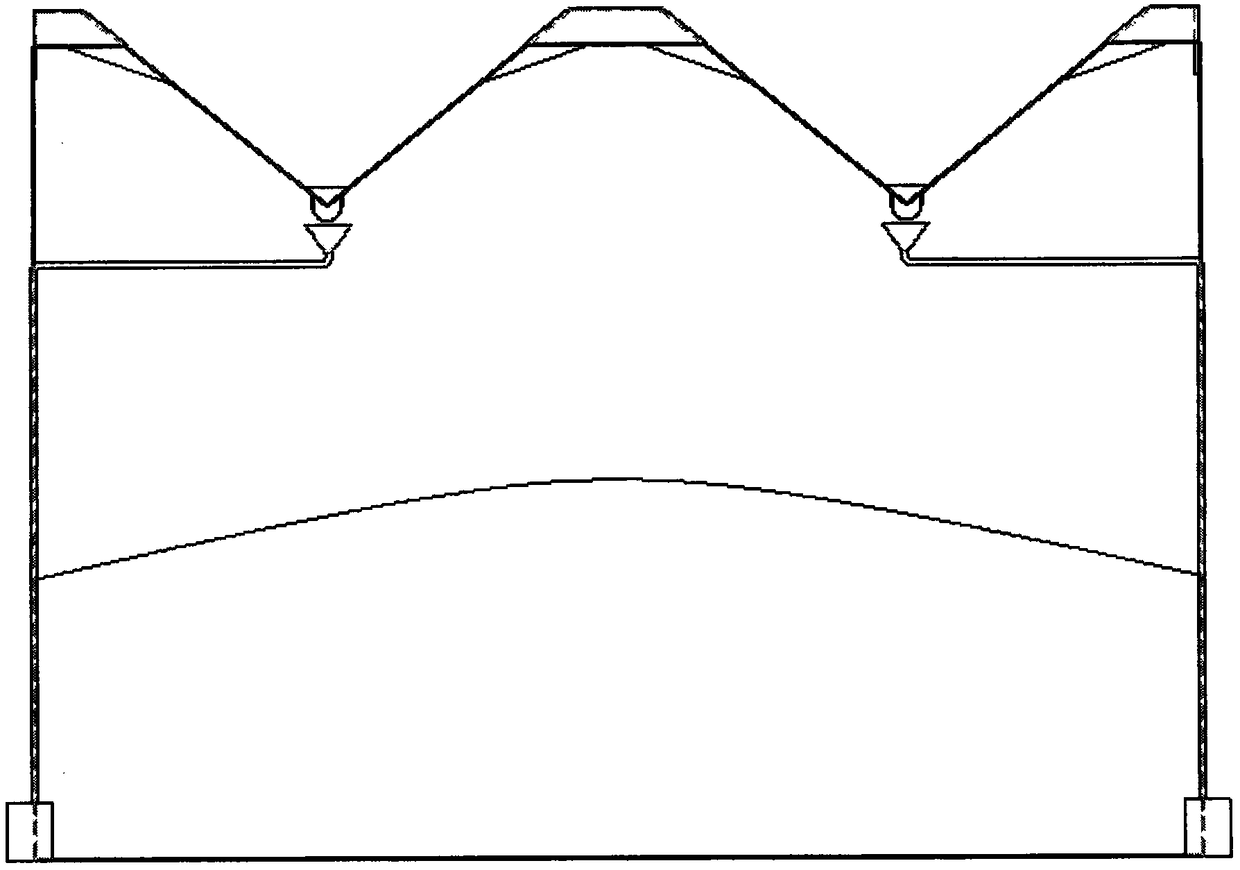

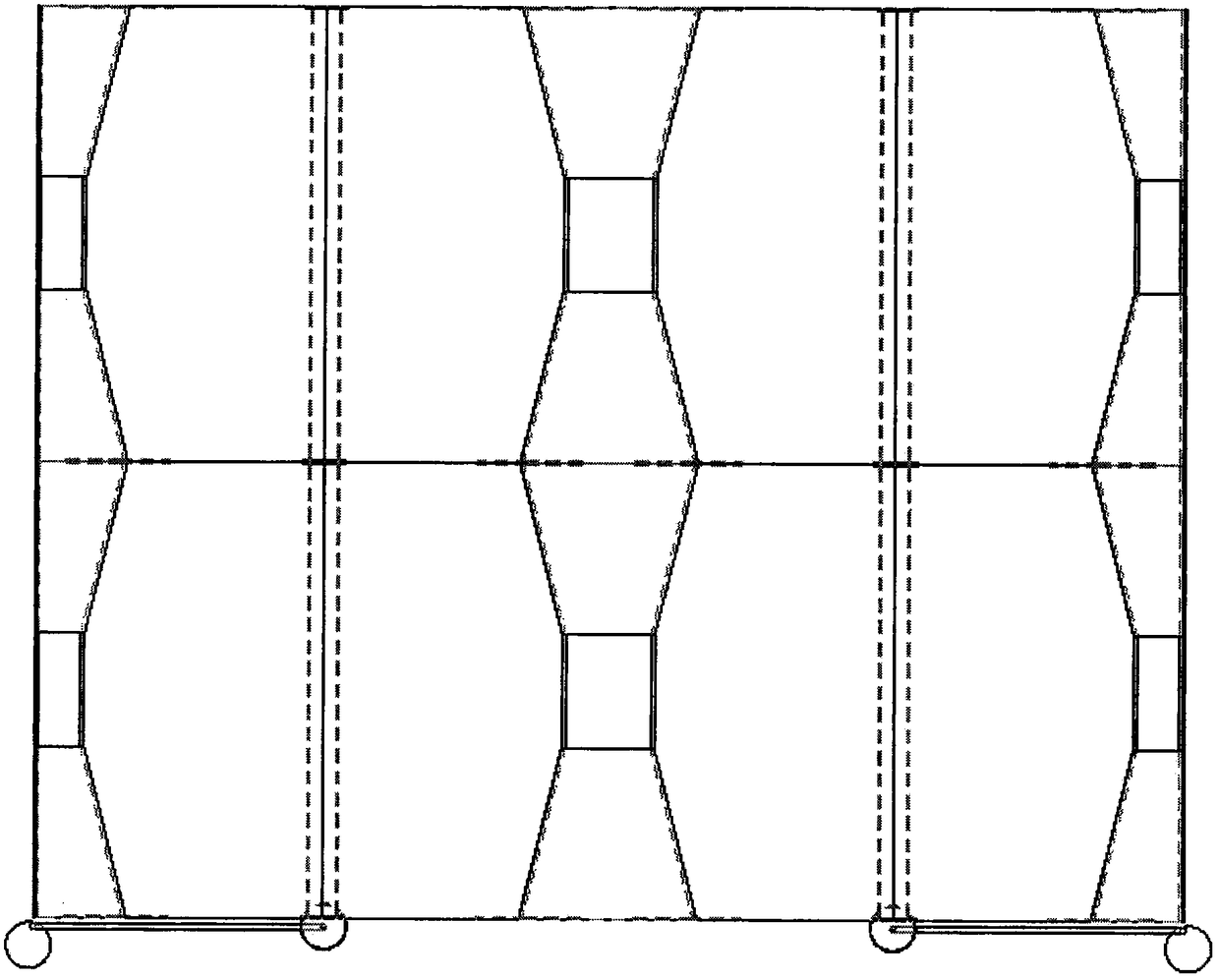

[0016] The structure and working process of the condensation collection system will be further described below in conjunction with the accompanying drawings.

[0017] 6 in the figure is the piled material, which contains a lot of water. During the fermentation process of the material, the temperature rises, and a large amount of water vapor will be generated when the pile is turned and aerated. Compared with air, water vapor has higher temperature and higher humidity, so it will move upward; 2 in the figure is the air extraction hole, which will continuously pump water vapor to the top of the fermentation chamber; the top of the fermentation chamber is installed with the Metal condensation plate, when water vapor encounters cold metal condensation plate, it will quickly condense into water droplets; and because the metal top plate shown in Figure 1 is in the shape of an inverted "M", a slope is formed, and the condensed water vapor It will flow into the water tank shown in Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com