Low-temperature curing baking type coating and preparation process

A low-temperature, coating technology, applied in the field of coatings, can solve the problems of large impact on the human body and the environment, low production efficiency, long drying time, etc., and achieve the effects of short baking time, improved production efficiency, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

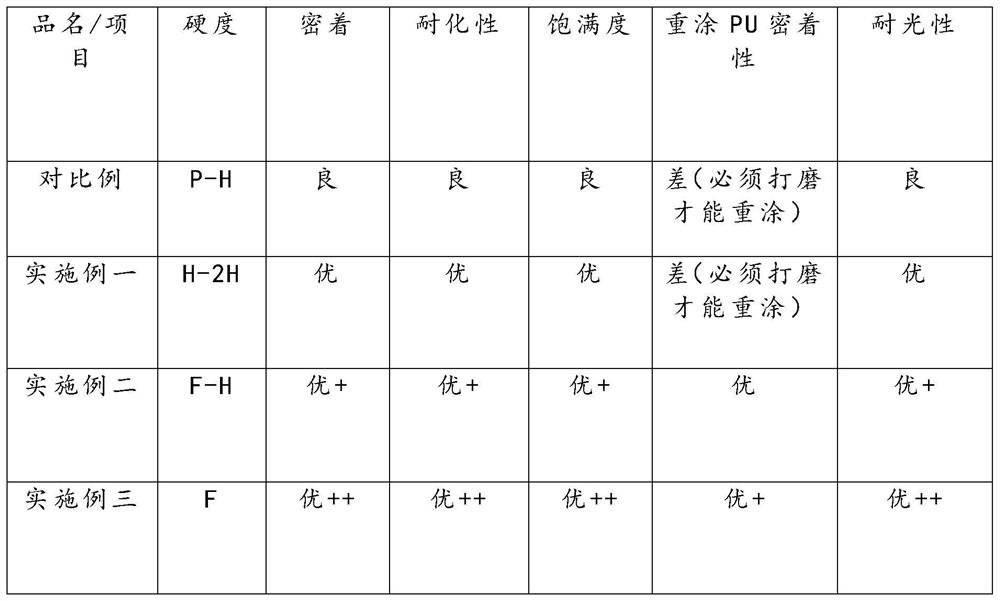

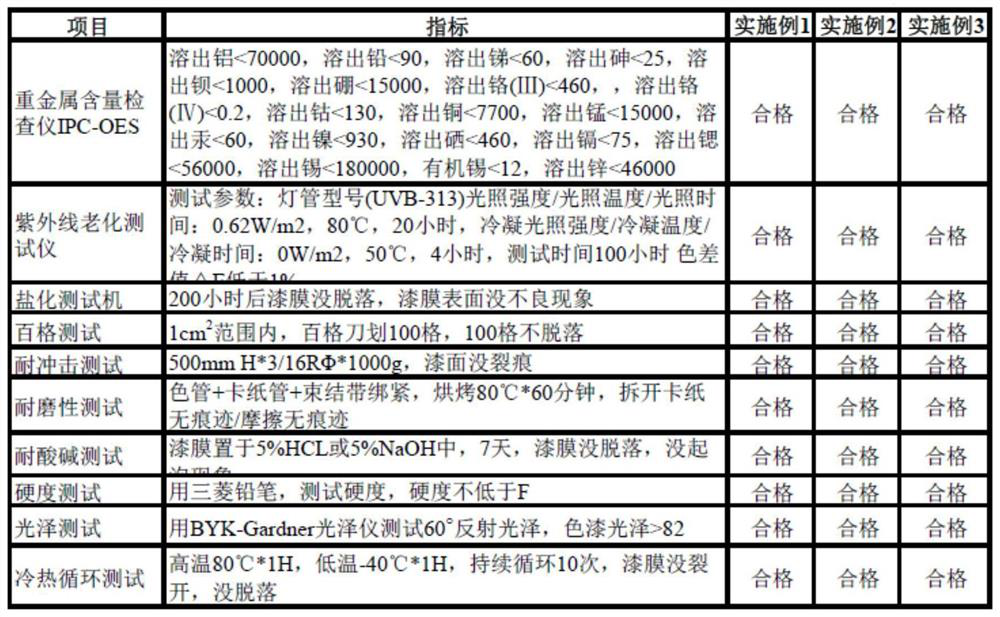

Examples

Embodiment 1

[0025] A low-temperature curing baking type coating, in parts by mass, comprising the following raw materials: 15 parts of acrylic resin, 15 parts of polyester resin, 1 part of diluent, 11 parts of amino resin, 2 parts of catalyst, 2 parts of rheology assistant, 2 parts defoamer, 2 parts stabilizer, 1 part leveling agent, 8 parts thinner.

[0026] Wherein, the low temperature curing baking type coating is prepared by the following preparation method, comprising the following steps:

[0027] S1: Weigh 15 parts of acrylic resin and 15 parts of polyester resin, add 1 part of diluent, stir evenly, then add 11 parts of amino resin, stir evenly, and use a high-speed mixer to mix and stir for 10 minutes after blanking is completed;

[0028] S2: After stirring, add 2 parts of catalyst, 0.5 part of leveling agent and 2 parts of defoamer, and continue mixing and stirring for 20-30 minutes using a high-speed mixer;

[0029] S3: After stirring, add 1 part of C-028 auxiliary agent, and us...

Embodiment 2

[0039] A low-temperature curing baking type coating, in parts by mass, comprising the following raw materials: 20 parts of acrylic resin, 20 parts of polyester resin, 5 parts of diluent, 15 parts of amino resin, 2 parts of catalyst, 2 parts of rheology assistant, 2 parts defoamer, 2 parts stabilizer, 1 part leveling agent, 10 parts thinner.

[0040] Wherein, the low temperature curing baking type coating is prepared by the following preparation method: comprising the following steps:

[0041] S1: Weigh 20 parts of acrylic resin and 20 parts of polyester resin, add 5 parts of diluent, stir evenly, then add 15 parts of amino resin, stir evenly, after cutting is completed, use a high-speed mixer to mix and stir for 10 minutes;

[0042] S2: After stirring, add 2 parts of catalyst, 0.5 part of leveling agent and 2 parts of defoamer, and continue mixing and stirring for 20-30 minutes using a high-speed mixer;

[0043] S3: After stirring, add 1 part of C-028 auxiliary agent, and use...

Embodiment 3

[0053] A low-temperature curing baking type coating, in parts by mass, comprising the following raw materials: 25 parts of acrylic resin, 25 parts of polyester resin, 10 parts of diluent, 20 parts of amino resin, 2 parts of catalyst, 2 parts of rheology assistant, 2 parts defoamer, 2 parts stabilizer, 1 part leveling agent, 12.5 parts thinner.

[0054] Wherein, the low temperature curing baking type coating is prepared by the following preparation method: comprising the following steps:

[0055] S1: Weigh 15 parts of acrylic resin and 15 parts of polyester resin, add 1 part of diluent, stir evenly, then add 11 parts of amino resin, stir evenly, and use a high-speed mixer to mix and stir for 10 minutes after blanking is completed;

[0056] S2: After stirring, add 2 parts of catalyst, 0.5 part of leveling agent and 2 parts of defoamer, and continue mixing and stirring for 20-30 minutes using a high-speed mixer;

[0057] S3: After stirring, add 1 part of C-028 auxiliary agent, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com