Combustion chamber structure of internal combustion engine

A combustion chamber and internal combustion engine technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as abnormal ignition, lack of cylinders in internal combustion engines, and ineffective release of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

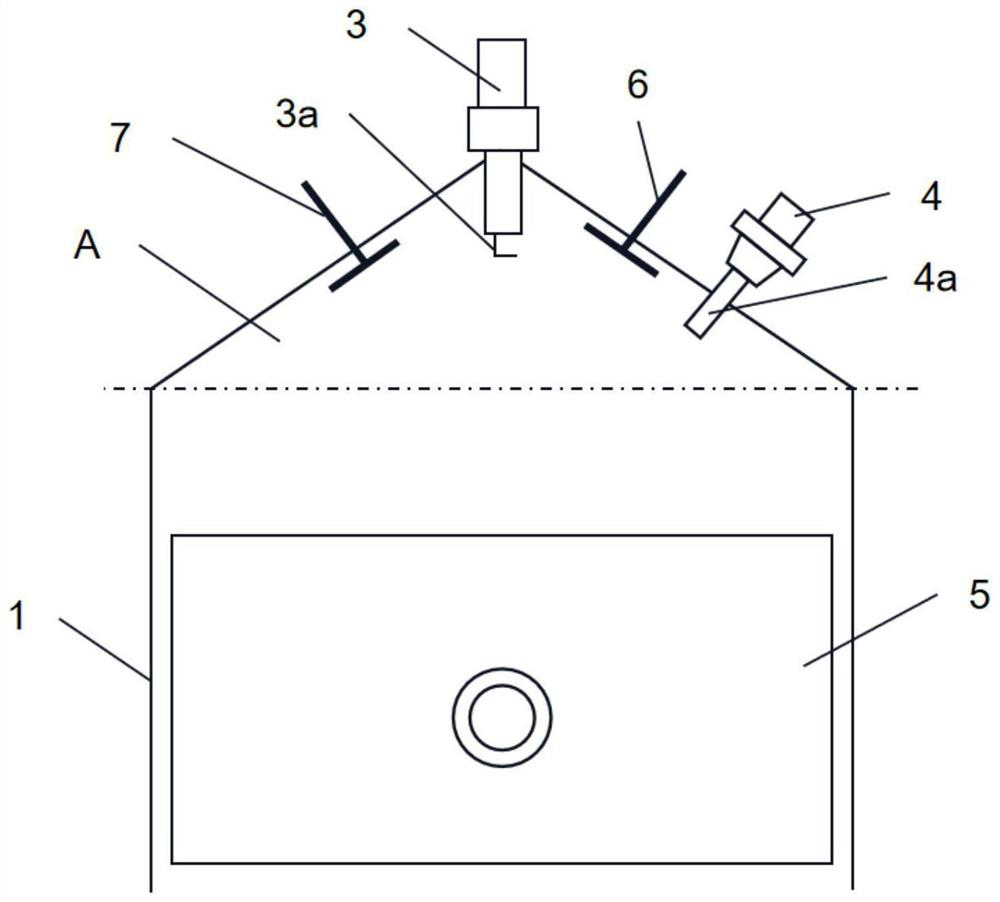

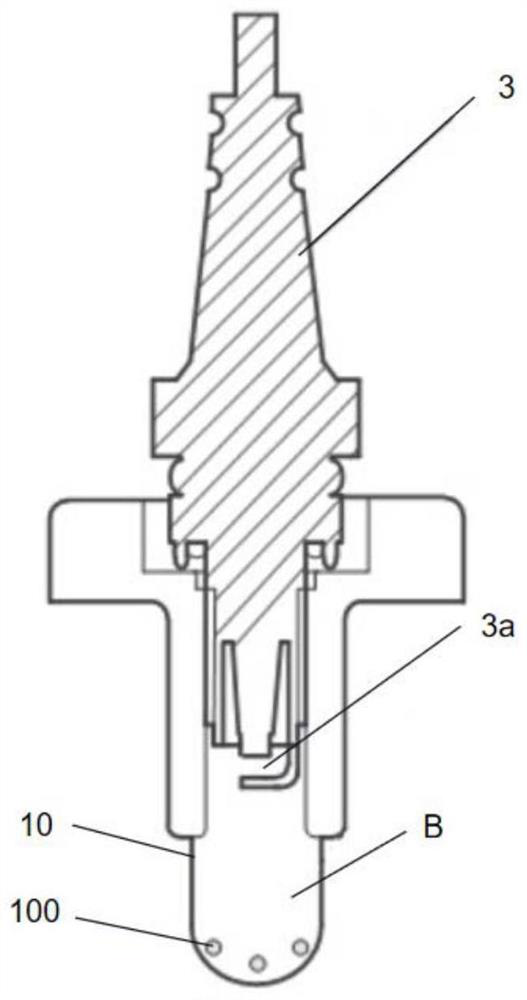

[0045] see image 3 , image 3 It is a partial cross-sectional view of the combustion chamber structure in Embodiment 1 of the present invention. Depend on image 3 It can be seen that the combustion chamber structure of the internal combustion engine includes a combustion chamber (not shown), an ignition device (not shown) and a choke casing 10, the combustion chamber is a closed cavity, and the ignition end 3a of the ignition device extends into the inside the combustion chamber. The choke casing 10 is located in the combustion chamber and surrounds the ignition end 3a of the ignition device to form a pre-combustion chamber B, and a main combustion chamber A is formed between the choke casing 10 and the inner wall of the combustion chamber. In this embodiment, the choke casing 10 is a circular arc surface that protrudes away from the ignition end 3a. The choke casing 10 is provided with a guide hole 110 for connecting the pre-combustion chamber B and the main combustion ...

Embodiment 2

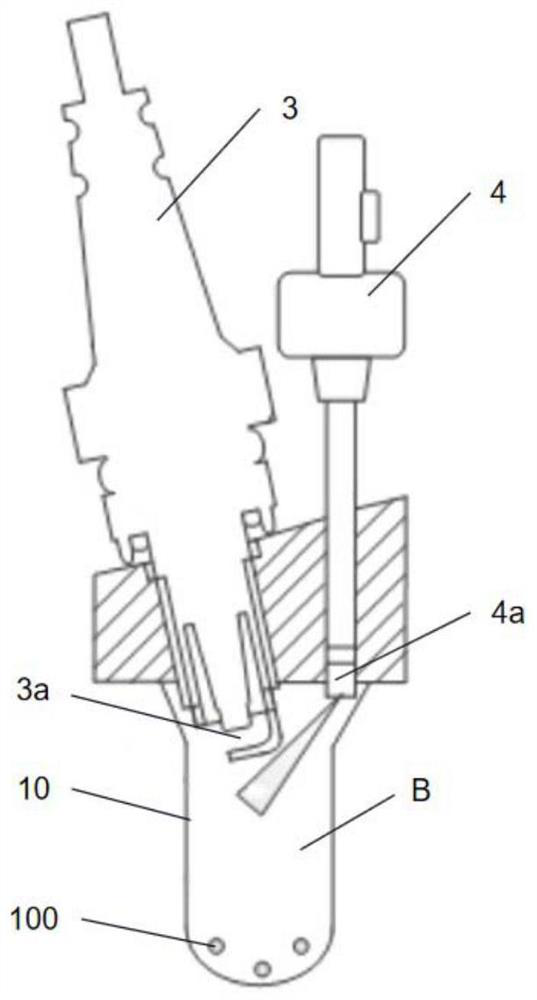

[0048] see Figure 4 , Figure 4 It is a partial cross-sectional view of the combustion chamber structure in Embodiment 2 of the present invention. Depend on Figure 4 It can be seen that the combustion chamber structure of the internal combustion engine includes a combustion chamber (not shown), an ignition device (not shown) and a choke casing 10, the combustion chamber is a closed cavity, and the ignition end 3a of the ignition device extends into the inside the combustion chamber. The choke casing 10 is located in the combustion chamber and surrounds the ignition end 3a of the ignition device to form a pre-combustion chamber B, and a main combustion chamber A is formed between the choke casing 10 and the inner wall of the combustion chamber. In this embodiment, the choke casing 10 is a circular arc surface that protrudes away from the ignition end 3a. A slit (not shown) is provided on the position where any extension surface D extends to the choke case 10, and the slit...

Embodiment 3

[0051] Please refer to FIG. 5 , FIG. 5( a ) is a top view of the combustion chamber structure in Embodiment 3 of the present invention, and FIG. 5( b ) is a longitudinal cross-sectional view of the combustion chamber structure in Embodiment 3 of the present invention. Depend on Figure 5(a) and 5(b) It can be seen that the choke casing 10 is a circular arc surface that protrudes away from the ignition end 3a. The difference between the combustion chamber structure of this embodiment and the combustion chamber structure of Embodiment 2 is that the baffle shell of this embodiment is provided with three flow guide holes.

[0052] combine Figure 5(a) and 5(b) , the first extension surface D1, the second extension surface D2 and the third extension surface D3 that intersect on the same intersection line C extend to the position of the choke case 10, and are respectively provided with a cutout (not shown in the figure), each cutout is at The choke case 10 is respectively formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com