Ultramicro filter membrane making wastewater treatment equipment

An ultra-microfiltration membrane and wastewater treatment technology, which is applied in filtration treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

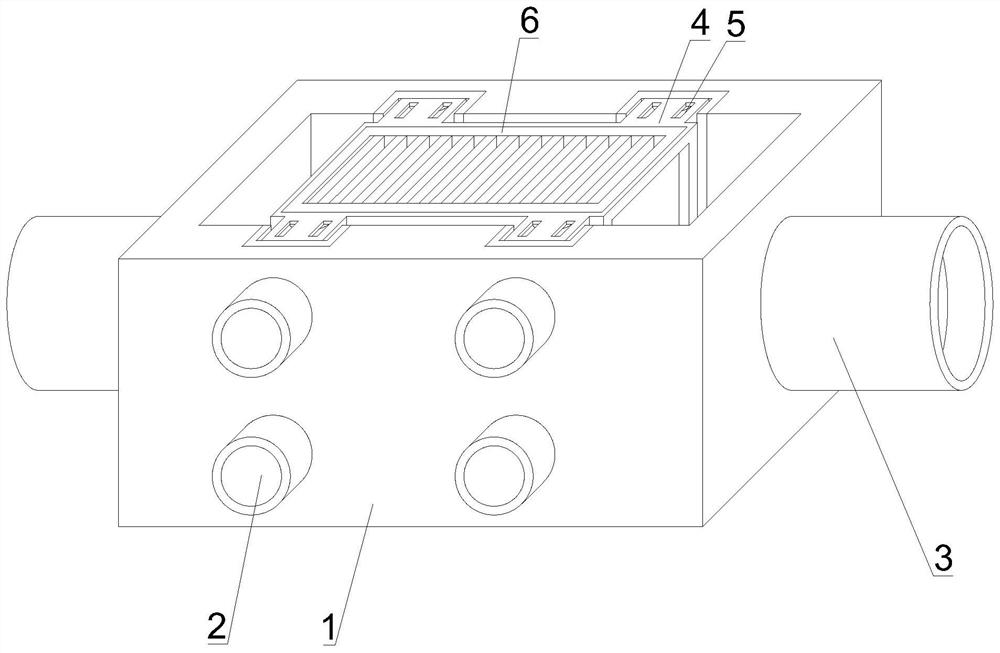

[0038] like Figure 1-6 As shown, the present invention provides an ultra-fine filtration membrane waste water treatment equipment, including an ultra-fine filtration membrane waste water processor 1, a pusher 2, a water inlet 3, a fixed hoisting shell 4, a hoisting clip 5 and an ultra-fine filtration membrane. Membrane filter 6, water inlets 3 are provided on the outer surfaces of both sides of the ultra-microfiltration membrane wastewater processor 1, and pushers 2 are detachably installed on the outer surfaces of the front and rear sides of the ultra-microfiltration membrane wastewater processor 1. The interior of the microfiltration membrane wastewater processor 1 is detachably lapped with a fixed hoisting casing 4, the interior of the fixed hoisting casing 4 is provided with an ultra-microfiltration membrane device 6, and the top outer surface of the fixed hoisting casing 4 is provided with a hoisting clipping buckle 5.

[0039] In the present embodiment, the cables are ...

Embodiment 2

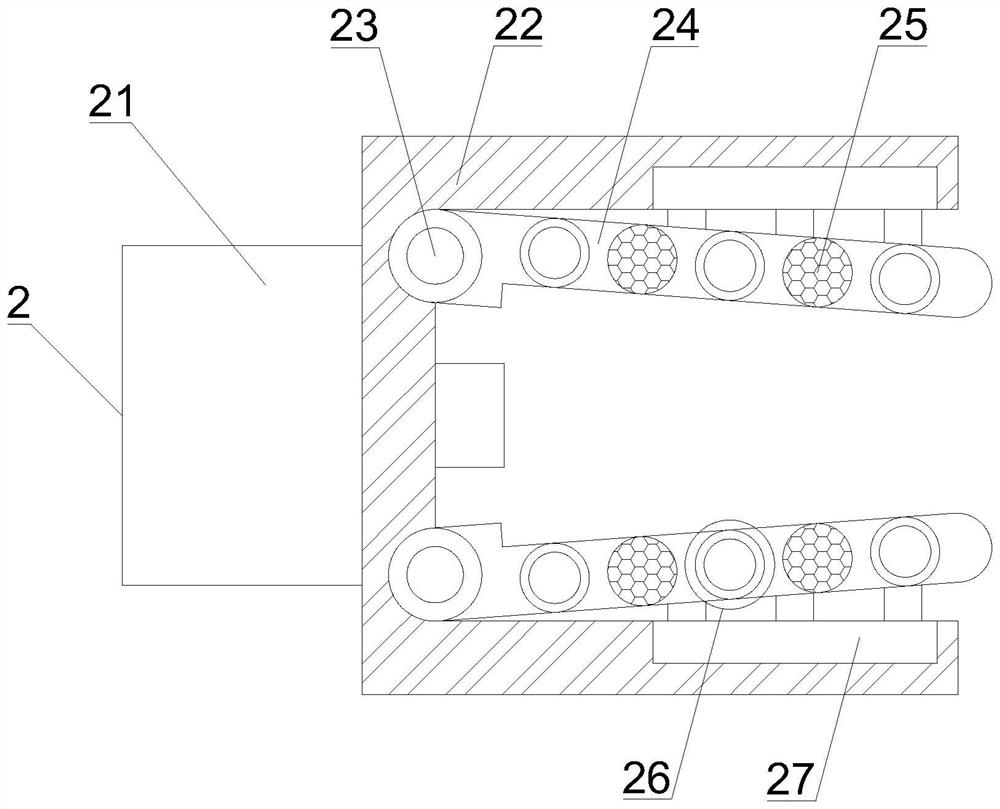

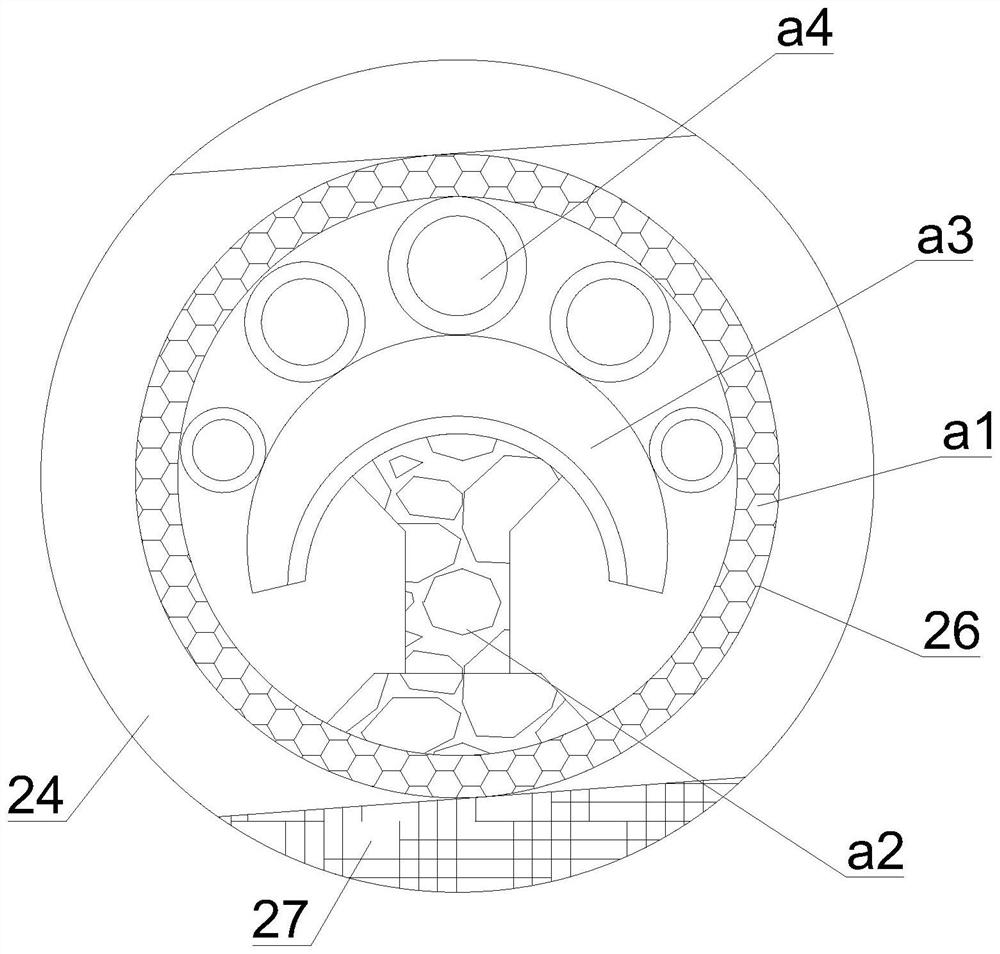

[0041] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a telescopic rod 21 is detachably connected to the output end of the pusher 2, and a card is detachably connected to one end of the telescopic rod 21 Adapter shell one 22, the inner surface of the left side of the snap joint shell 22 is provided with a shaft wheel 23, and the outer surface of the shaft wheel 23 is detachably connected with a press-fitted soft plate 24, which is squeezed and fitted to the soft board. The inner surface of 24 is provided with elastic soft balls 25, the inside of the pressing and fitting soft plate 24 is provided with friction pressing balls 26, and small pushers are detachably installed on the inner surfaces of the upper and lower sides of the snap-on sleeve one 22. 27. The output end of the small pusher 27 extends to the outer surface of the pressing and fitting soft plate 24. The friction pressing ball 26 includes an el...

Embodiment 3

[0044] like Figure 1-6 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, an empty groove 61 is provided at the bottom of the ultra-micro filter membrane 6, and the outer surfaces of the two sides of the ultra-micro filter membrane 6 are located on the lower side. A snap-on sleeve 2 62 is provided, and the snap-on sleeve 2 62 is located on the inner surfaces of both sides of the empty slot 61 . An expansion bag 64 is movably lapped on the surface, a push plate 65 is movably lapped on the outer surface of the expansion bag 64, and a squeeze sealing block 66 is detachably connected on the top outer surface of the push plate 65. A vent 67 is provided on the inner surface of the bottom of the membrane, the outer surface of the extrusion sealing block 66 is movably lapped on the inner surface of the vent 67, and the outer surfaces of the two sides of the ultra-micro filter membrane 6 are provided with water passages 68, An ultra-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com