Automatic efficient tea planting equipment

A high-efficiency, high-efficiency technology, which is applied in planting methods, excavation/covering ditches, agricultural gas emission reduction, etc., can solve the problems of difficult drilling pit spacing and size, cumbersome, large undulating slopes, etc., to achieve stable operation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

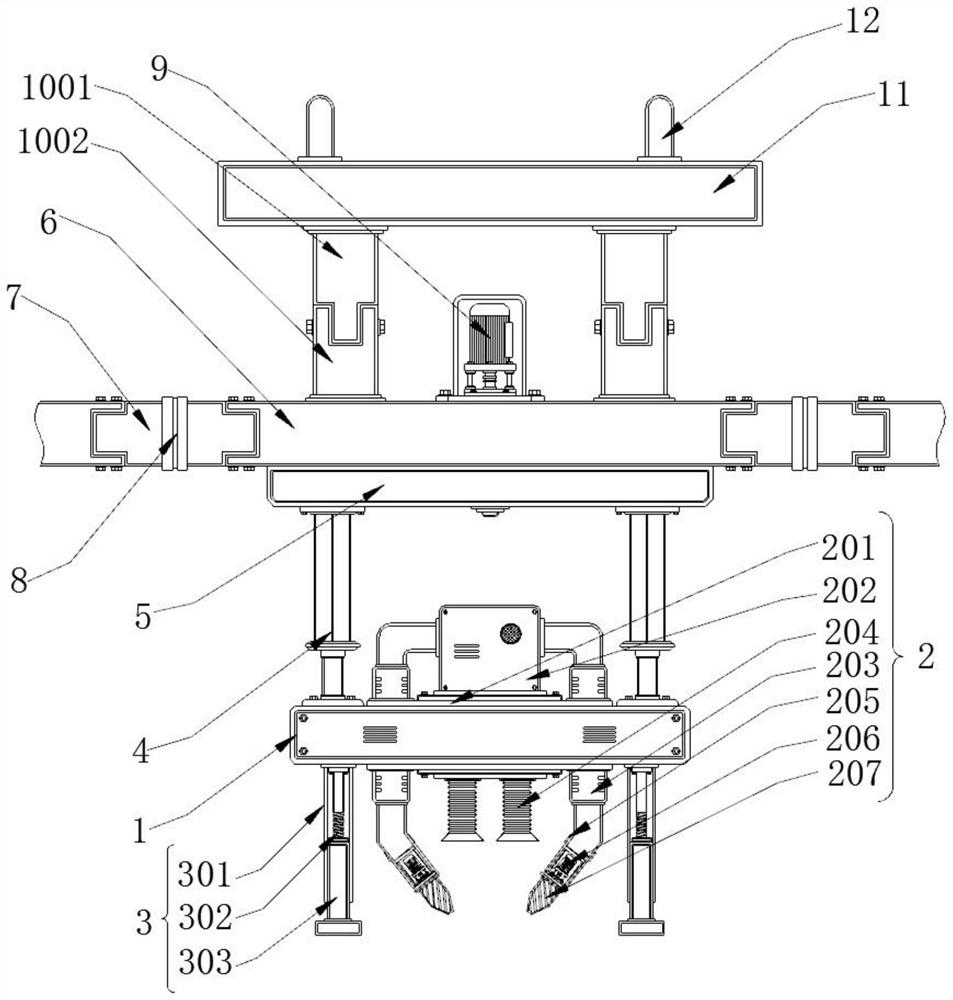

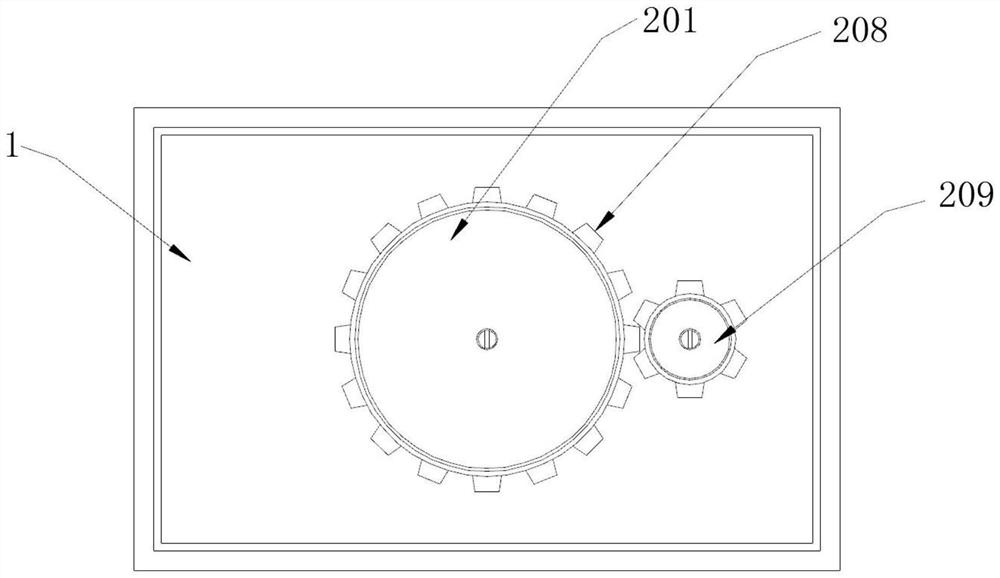

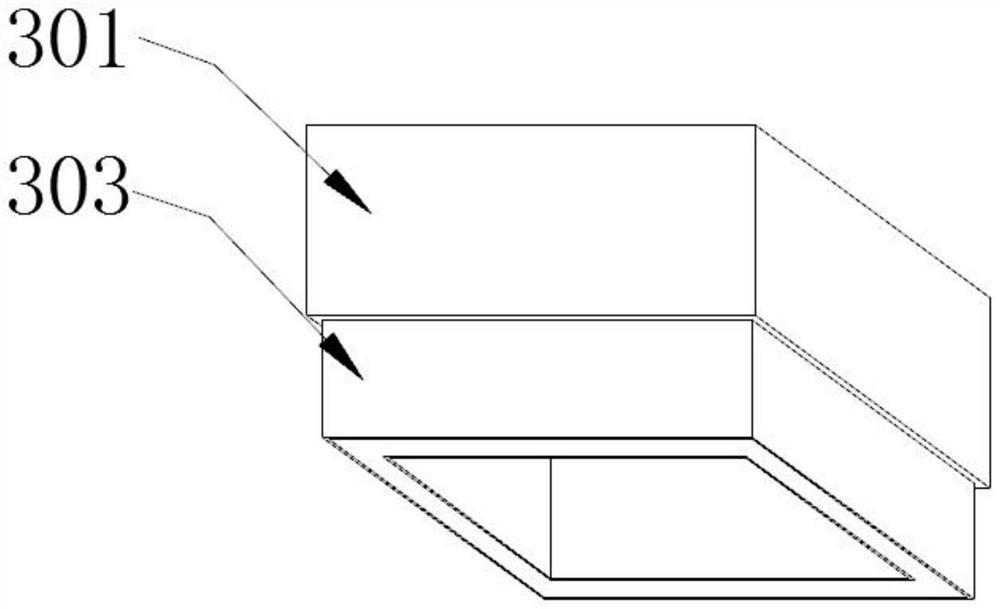

[0032] See Figure 1-9 , the present invention provides a technical solution: a tea automated efficient planting apparatus, comprising a fixed seat 1, a drilling pit assembly 2 and a planting table 18, the inner side of the fixed seat 1 is placed with a drilling pit assembly 2, the drilling pit assembly 2 includes a rotating seat 201, a suction box 202, an auxiliary pipe body 203, a suction pipe 204, a connecting groove 205, a first motor 206, a drill bit 207, a rotating tooth 208 and an active gear 209, the top outer side of the rotating seat 201 is provided with a suction box 202, And the external sides of the suction box 202 is connected to the auxiliary tube body 203, the bottom outer side of the suction box 202 is provided with a suction tube 204, the outer surface of the auxiliary tube body 203 is provided with a connecting groove 205, the front section of the auxiliary tube body 203 is connected to the first motor 206, and the output end of the first motor 206 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com