Efficient fertilizing device and material mixing, charging, fertilizing and push-pull mechanism thereof

A fertilization device and material mixing technology, which is applied to fertilization devices, mixers with rotating stirring devices, mixers, etc., can solve the problems of difficult discharge, uneven fertilizer mixing, and inconvenient use by workers of different heights. The effect of reducing labor intensity, improving comfort, and expanding practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0045] The following are specific implementations of the high-efficiency fertilization device of the present invention.

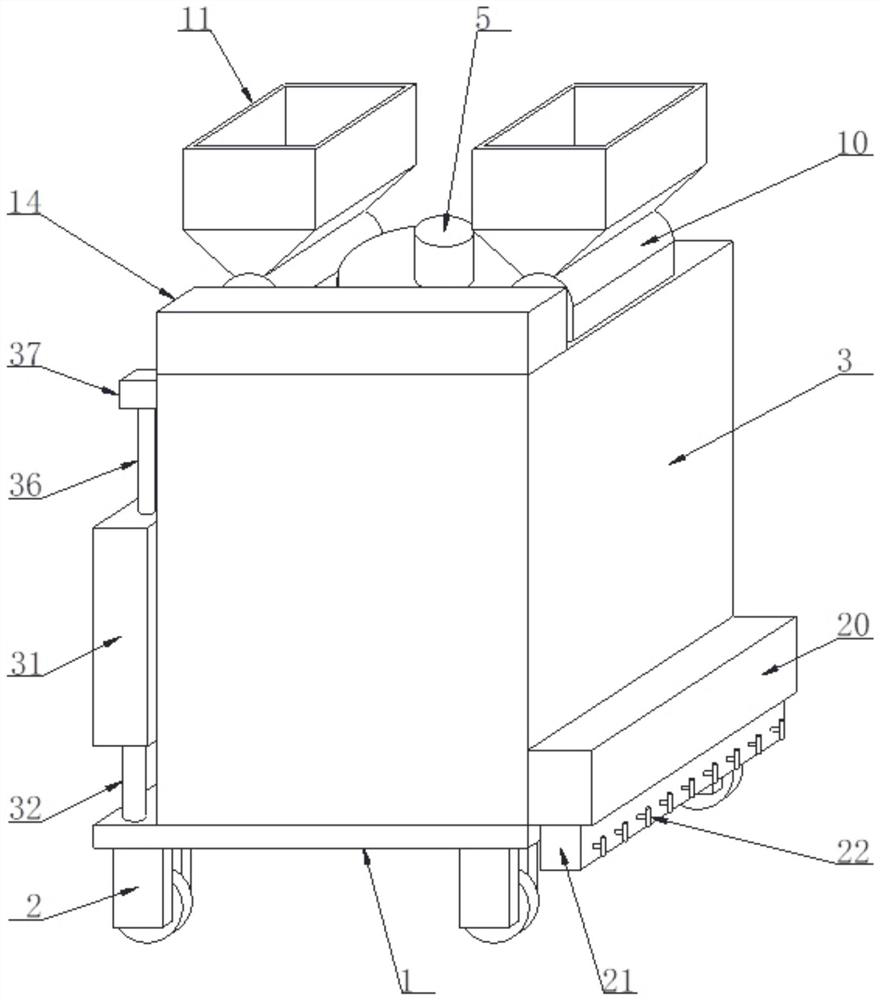

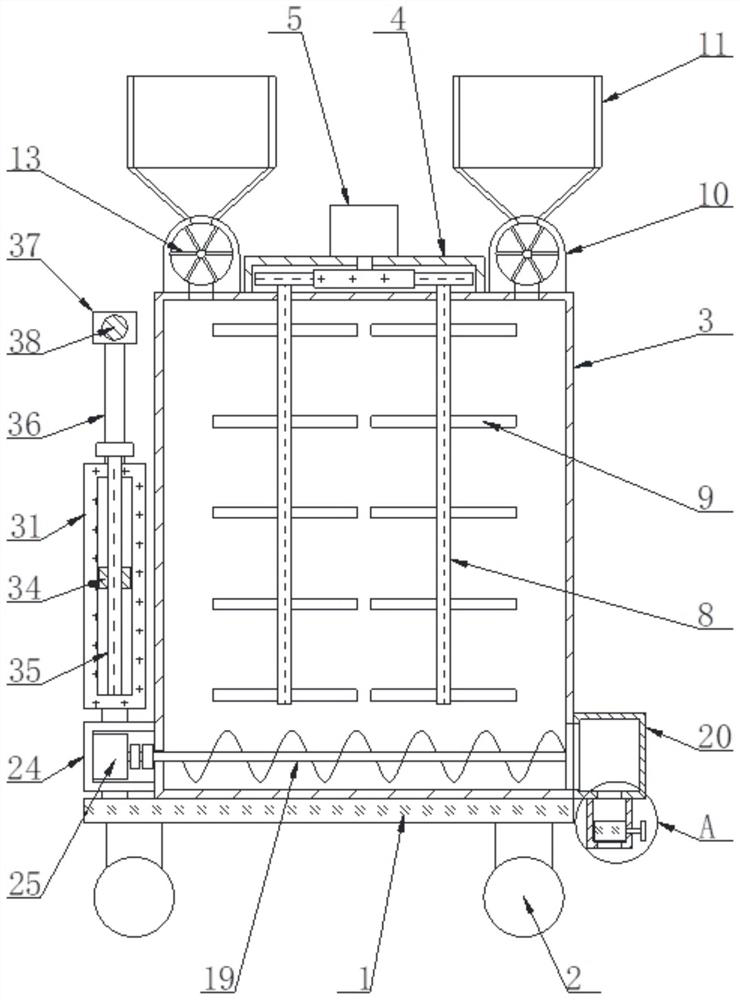

[0046] The high-efficiency fertilization device under the specific embodiment, such as Figure 1 to Figure 10 As shown, including mixing mechanism, feeding mechanism, fertilization mechanism and push-pull mechanism,

[0047] like figure 1 and figure 2 As shown, the mixing mechanism includes a support plate 1, a walking wheel set 2, a mixing housing 3, an installation housing 4, a mixing motor 5, a main gear 6, a secondary gear 7, a stirring shaft 8 and a stirring blade 9, The bottom of the support plate 1 is fixedly connected to the walking wheel group 2, the top of the support plate 1 is fixed to the mixing shell 3, the top of the mixing shell 3 is provided with a feeding mechanism, and the top of the mixing shell 3 is fixed to Install the housing 4, the top of the installation housing 4 is affixed to the mixing motor 5, the output end of the mixing mo...

specific Embodiment approach 2

[0055] The following are specific implementations of the high-efficiency fertilization device of the present invention.

[0056] The high-efficiency fertilization device under the specific embodiment is further limited to the specific embodiment one, as follows:

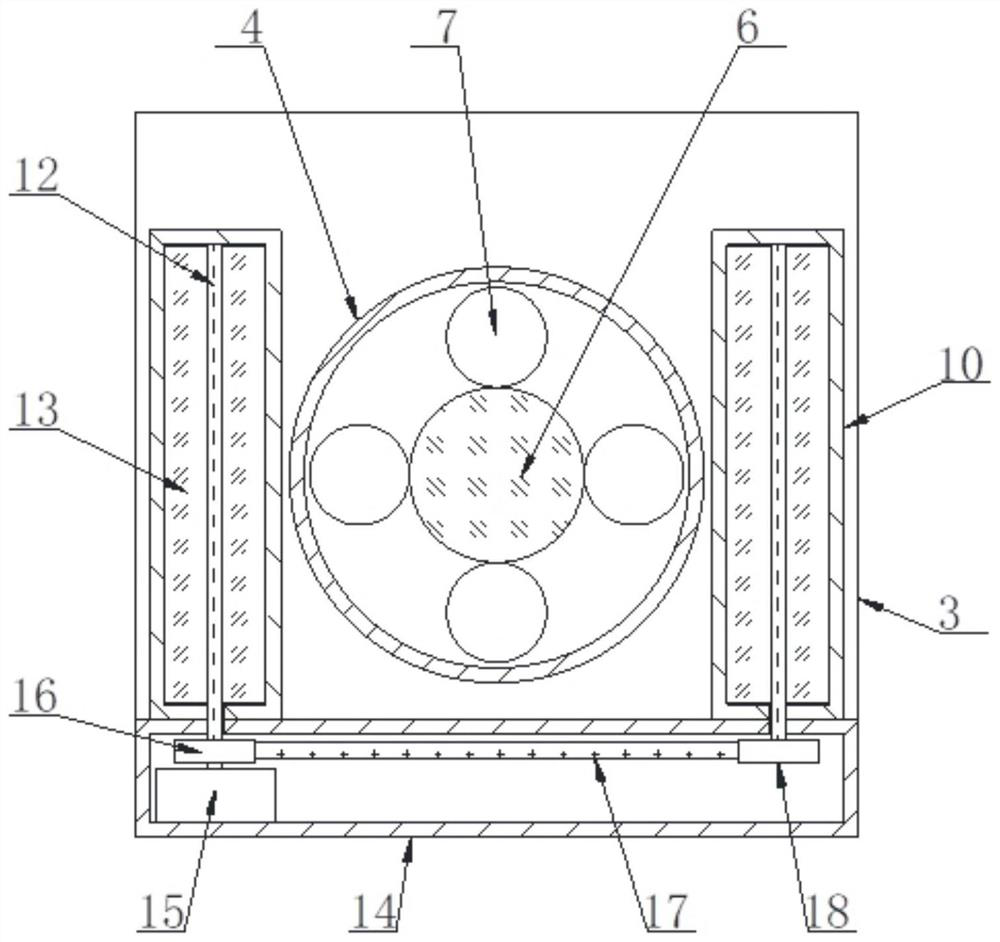

[0057] like figure 2 and Figure 4 As shown, the side of the main gear 6 is meshed with four auxiliary gears 7 distributed in an annular array, the top surface of the installation housing 4 is provided with installation holes, and the output end of the mixing motor 5 passes through the installation holes and extends To the inner cavity of the installation shell 4, the mixing shell 3 is provided with four rotating holes distributed in an annular array, the bottom end of the stirring shaft 8 passes through the rotating holes and extends to the inner cavity of the mixing shell 3, The surface of the stirring shaft 8 is fixed with several stirring blades 9, and the bottom of the support plate 1 is fixed with four walki...

specific Embodiment approach 3

[0058] The following are specific implementations of the high-efficiency fertilization device of the present invention.

[0059] The high-efficiency fertilization device under the specific embodiment is further limited to the specific embodiment one, as follows:

[0060] like Figure 4 and Figure 5 As shown, the top and bottom of the fixed housing 10 are provided with a first feeding port, the top surface of the mixing housing 3 is provided with a second feeding port, and the fixed housing 10 is close to the side of the supporting housing 14 A first preset hole is opened, and a second preset hole is opened on one side of the support shell 14 close to the fixed shell 10, and one end of the rotating shaft 12 is rotatably connected to the side wall of the inner cavity of the fixed shell 10, The other end of the rotating shaft 12 passes through the first preset hole and the second preset hole and extends to the inner cavity of the support housing 14. The surface of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com