Sampling inspection method and device for safety automatic device based on multi-source data

A safe, automatic, multi-source data technology, applied in circuit devices, information technology support systems, electrical components, etc., can solve the problem of not being able to detect abnormal operation of primary equipment in time, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

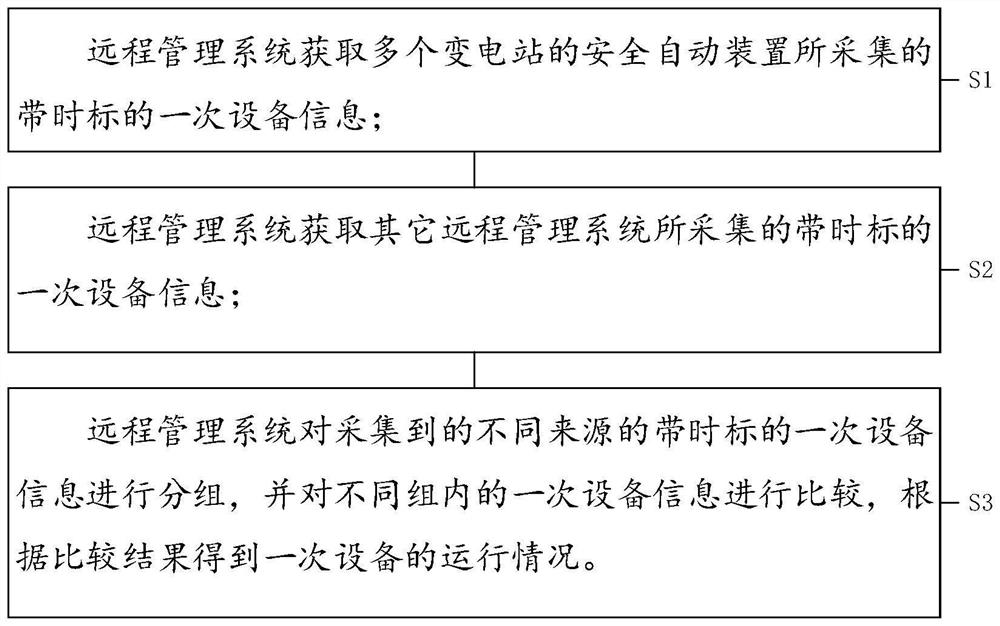

[0031] like figure 1 As shown, the present invention discloses a multi-source data-based sampling and inspection method for automatic safety devices, which collects and analyzes data for secondary equipment in a power supply system, and discovers abnormal conditions of primary equipment in time, so as to make the power supply system more efficient. Safe and reliable, it mainly includes the following steps:

[0032] Step S1, the remote management system acquires primary equipment information with time stamps collected by the safety automatic devices of multiple substations;

[0033] Step S2, the remote management system obtains primary equipment information with time stamps collected by other remote management systems;

[0034] Step S3, the remote management system groups the collected primary equipment information with time stamps from different sources, compares the primary equipment information in different groups, and obtains the operation status of the primary equipment a...

Embodiment 2

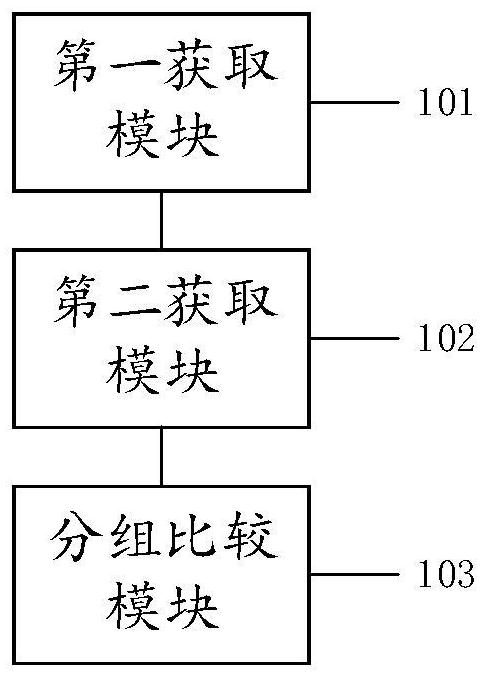

[0083] The invention also discloses a multi-source data-based sampling and inspection device for an automatic safety device, comprising: a first acquisition module 101, a second acquisition module 102 and a grouping comparison module 103;

[0084] The first acquisition module 101 is used for the remote management system to acquire primary equipment information with time stamps collected by the safety automatic devices of a plurality of substations;

[0085] The second acquisition module 102 is used for the remote management system to acquire primary equipment information with time stamps collected by other remote management systems;

[0086] The grouping comparison module 103 is used for the remote management system to group the collected primary equipment information with time stamps from different sources, and compares the primary equipment information in different groups, and obtains the operation status of the primary equipment according to the comparison result. .

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com