High-temperature pump cooling structure

A cooling structure and high-temperature pump technology, applied in the field of high-temperature pump cooling, can solve the problems of failure and the heat exchange effect of the high-temperature pump is not very obvious, and achieve the effects of temperature balance, reliability, and heat exchange efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following combined with the attachment of the present invention is further explained in detail.

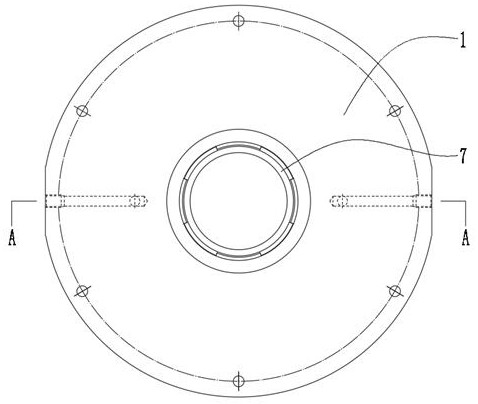

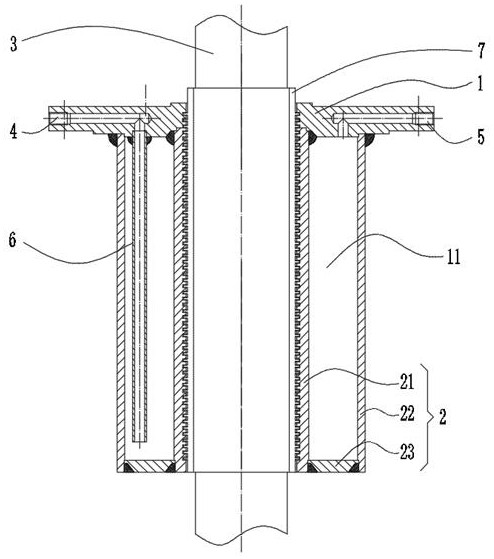

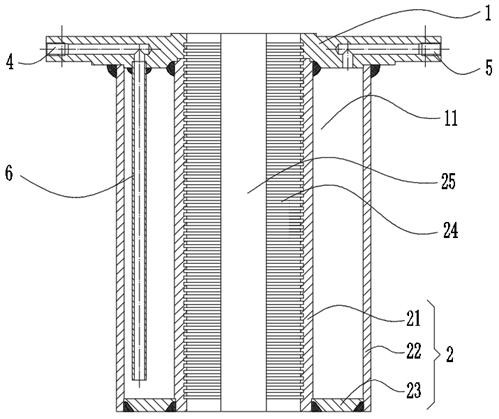

[0018] like figure 1 and figure 2 It shows that a high temperature pump cooling structure is provided in this embodiment, including a closed cooling mechanism set on the pump axis 3. The closed cooling mechanism consists of a horizontal top cover 1 and a base 2 in the level. Structure, etc., and the top cover 1 in this example adopts a ring block structure, which matches the diameter of the pump axis. The top surface of the top cover is evenly opened with multiple installation holes in a uniform intervals in the edge of the top cover. The holes are fixed to the top cover; the base 2 is an open -end opening, and the closed ring tank structure is closed at one end. The inner diameter is matched with the diameter of the pump axis. The body is closed to form a ring cooling cavity 11, and the ring cooling cavity is used for loading liquid (such as cooling water, etc.) to change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com