Module wall for house building

A technology for building walls and buildings, which is applied to buildings, building components, building structures, etc., can solve problems such as low construction efficiency, wall shaking, and wall connection is not tight, and achieves improved installation speed, improved installation efficiency, The effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

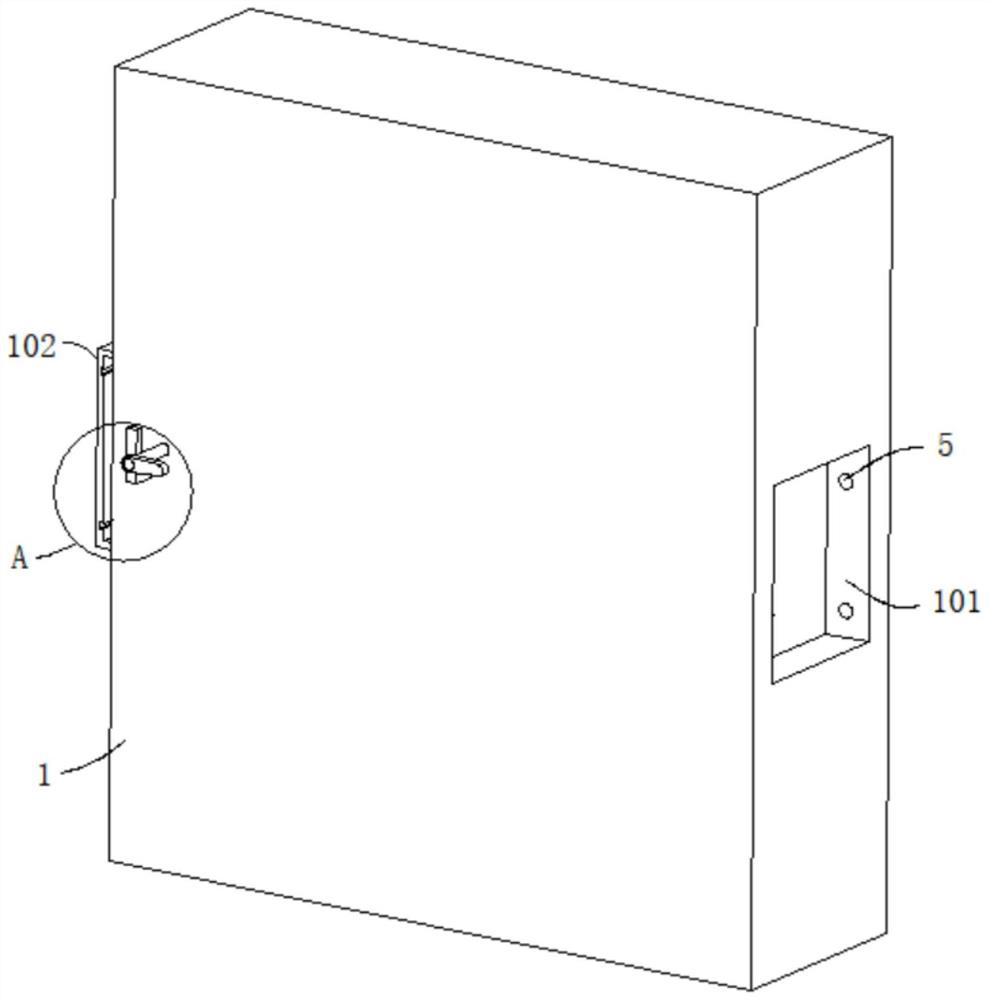

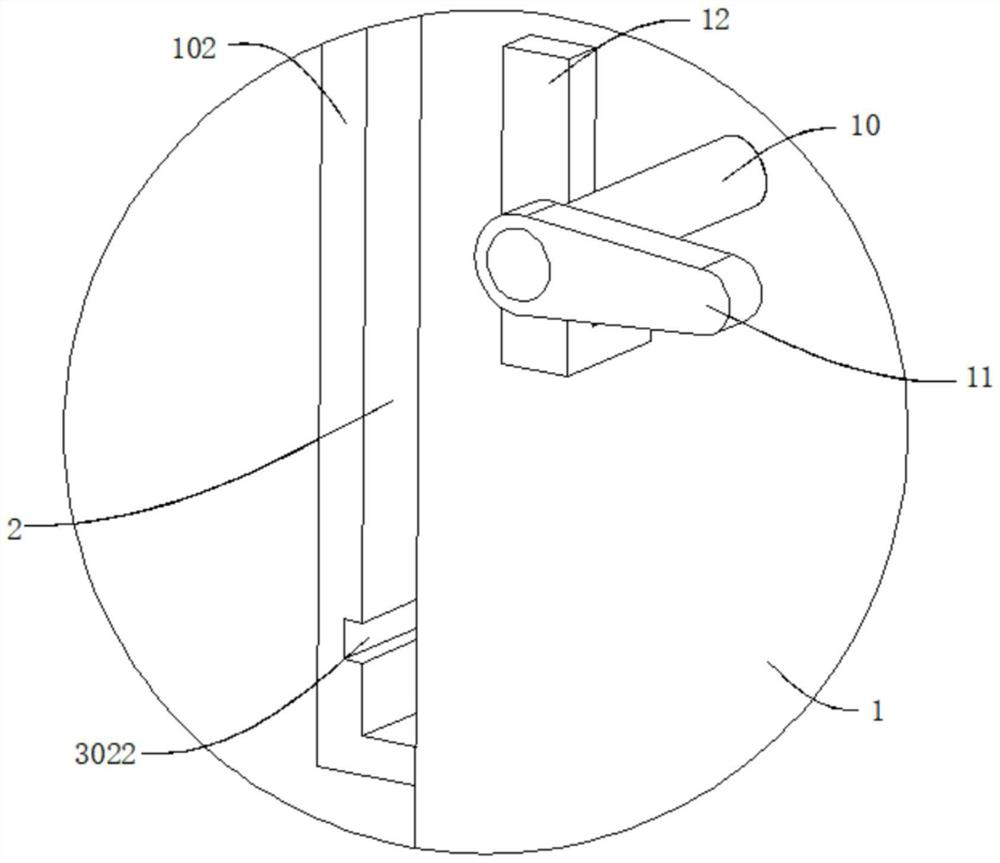

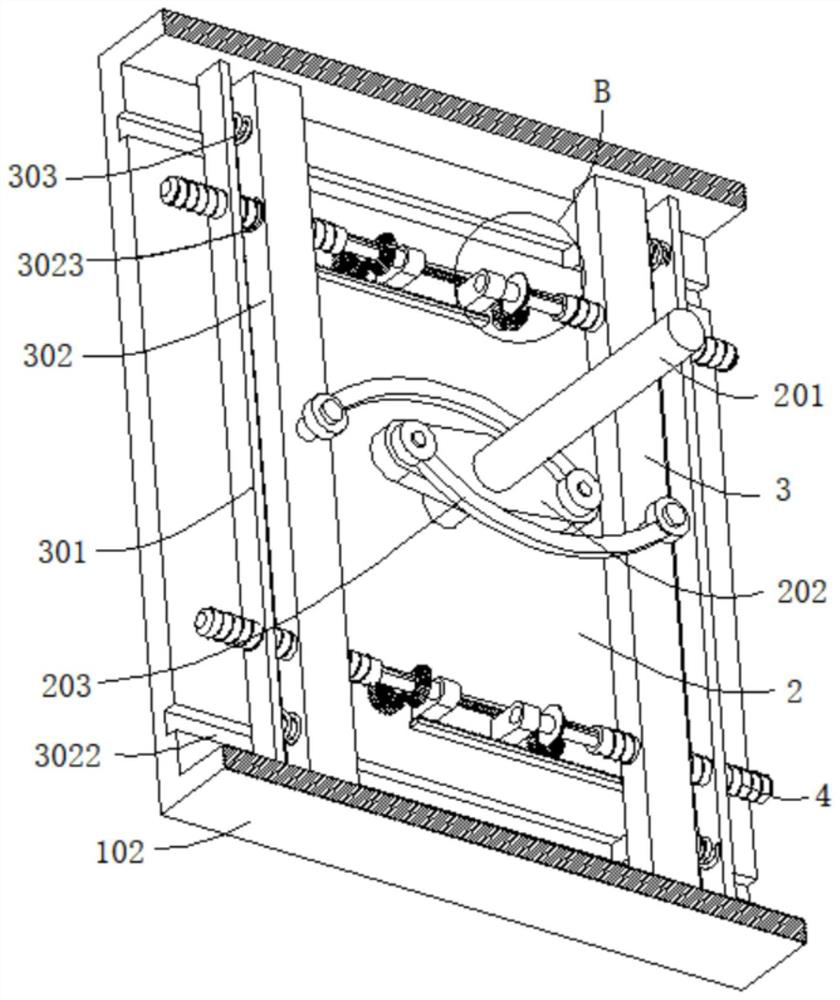

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 , a modular wall used in building construction, comprising a building wall 1, a slot 101 is provided on one side of the building wall 1, and an insert block 102 is arranged on the side of the building wall 1 away from the slot 101, and the insert block 102 A cavity 2 is provided, and a moving plate 3 is slidably connected to both sides of the inner wall of the cavity 2. The moving plate 3 is movable against the inner wall of the slot 101. A linkage mechanism for driving the moving plate 3 to move is arranged in the cavity 2. The moving plate 3 is connected with a stud 4 through bearing rotation, a transmission mechanism for driving the rotation of the stud 4 is arranged in the cavity 2, and the displacement of the moving plate 3 drives the transmission mechanism to work, and a slot 101 is provided with a The screw hole 5 and the stud 4 are provided with a clamping mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com