Artificial magnetic soil and preparation method and application thereof

A magnetic and artificial technology, applied in applications, soil conditioning materials, chemical instruments and methods, etc., can solve problems such as undeveloped utilization, improve soil quality, improve biochemical improvement and restoration, and promote reproduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

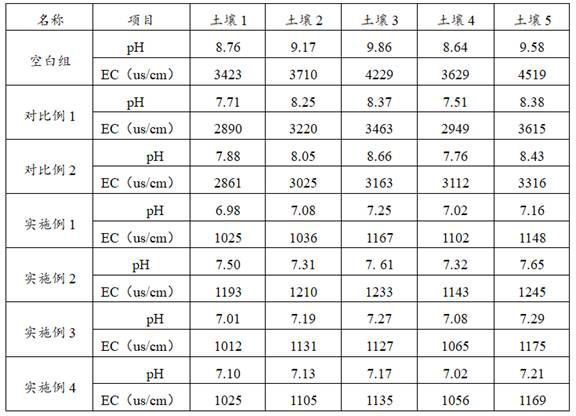

Embodiment 1

16 parts of gasifier ash, 8 parts of fly ash, 20 parts of municipal sludge, 6 parts of river and lake bottom mud, 15 parts of artificial zeolite, 6 parts of iron tailings, 7 parts of magnesium tailings, metallurgical melting 4 parts of slag, 3 parts of phosphogypsum, 1.5 parts of lignite, 4 parts of quicklime, and 12 parts of organic matter.

[0092] The above-mentioned gasifier ash, lignite, iron tailings, magnesium tailings, metallurgical slag, phosphogypsum, lignite, quicklime and organic matter are pulverized into fine particles with a particle size of 150 μm, and fly ash and gypsum powder are mixed; Dry and dispose of municipal sludge and river and lake bottom mud; make artificial zeolite molecular sieves into spheres with a diameter of 2 cm, soak them in chemicals for 30 minutes, then clean them and dry them for later use;

Rinse the pulverized mixture to leach out the salt, so as not to cause soil salinization again; after rinsing, perform high temperature treatment at 1...

Embodiment 2

21 parts of gasifier ash, 4 parts of fly ash, 13 parts of municipal sludge, 12 parts of river and lake bottom mud, 10 parts of artificial zeolite, 2.5 parts of iron tailings, 2.5 parts of magnesium tailings, metallurgical melting 4 parts of slag, 3 parts of phosphogypsum, 1.5 parts of lignite, 4 parts of quicklime, and 12 parts of organic matter.

[0096] The above-mentioned gasifier ash, lignite, iron tailings, magnesium tailings, metallurgical slag, phosphogypsum, lignite, quicklime and organic matter are pulverized into fine particles with a particle size of 150 μm, and fly ash and gypsum powder are mixed; Dry and dispose of municipal sludge and river and lake bottom mud; make artificial zeolite molecular sieves into spheres with a diameter of 2 cm, soak them in chemicals for 30 minutes, then clean them and dry them for later use;

Rinse the pulverized mixture to leach out the salt, so as not to cause soil salinization again; after rinsing, perform high temperature treatment...

Embodiment 3

23 parts of gasifier ash, 6 parts of fly ash, 15 parts of municipal sludge, 15 parts of river and lake bottom mud, 10 parts of artificial zeolite, 5 parts of iron tailings, 5 parts of magnesium tailings, metallurgical melting 5 parts of slag, 2 parts of phosphogypsum, 2 parts of lignite, 3 parts of quicklime, and 9 parts of organic matter.

[0100] The above-mentioned gasifier ash, lignite, phosphogypsum, lignite, quicklime and organic matter are pulverized into fine particles with a particle size of 180 μm, mixed with fly ash and gypsum powder; the municipal sludge and river and lake bottom mud are dried and disposed of; The artificial zeolite molecular sieve is made into a spherical shape with a diameter of 5 cm, soaked in the medicine for 30 minutes, then cleaned and dried for use;

Rinse the pulverized mixture to leach out the salt so as not to cause soil salinization again; after rinsing, perform high temperature treatment at 200 degrees Celsius; sterilize municipal sludge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com