Universal silicon product processing turntable structure

A general-purpose, product-based technology, applied in final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of inability to adapt to multi-category products, frequent replacement of silicon component product categories, and difficulty in fixed processing methods. Timely adjustment and other issues to achieve the effect of shortening the switching cycle, good versatility and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

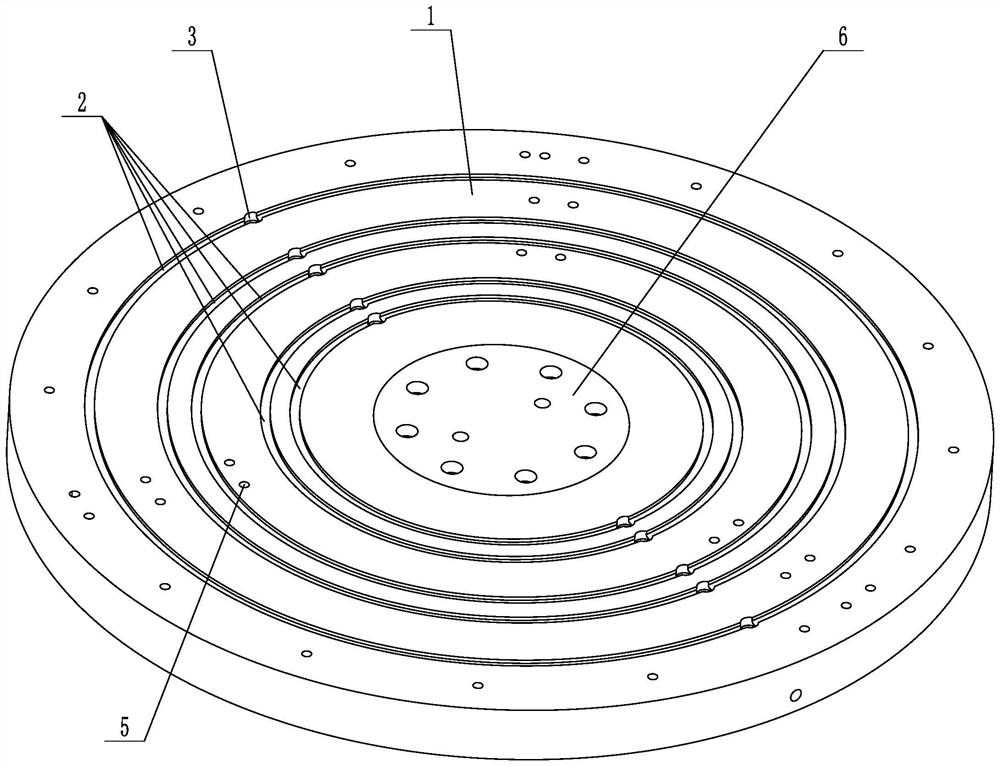

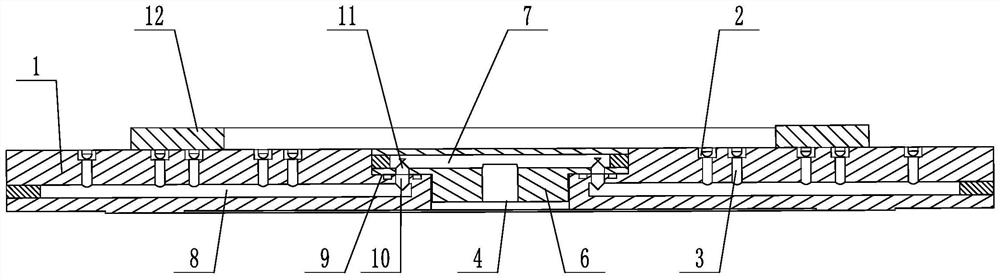

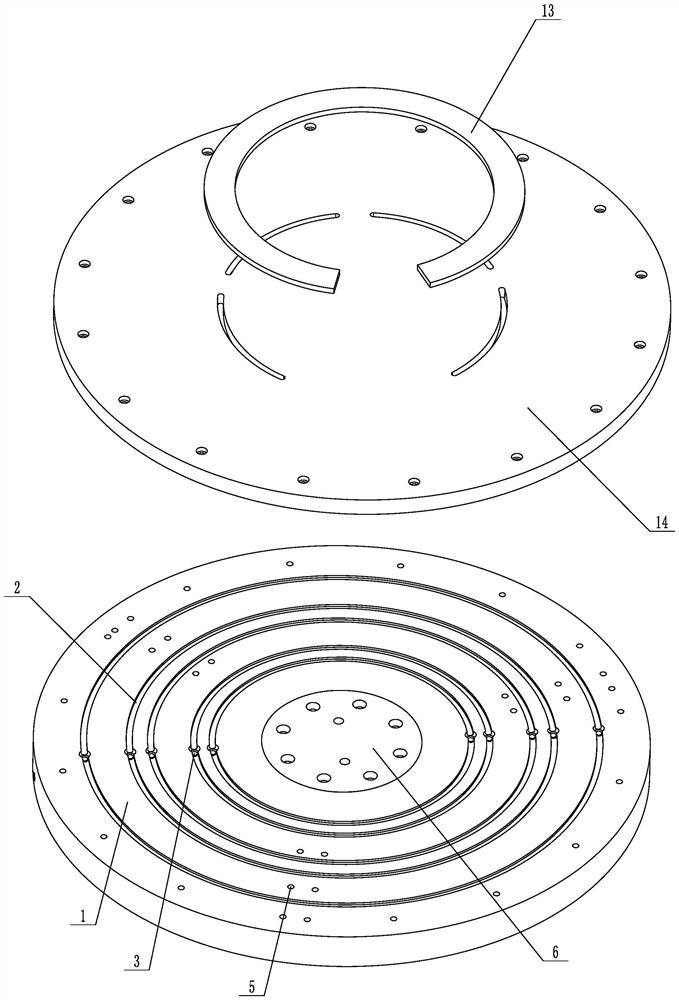

[0025] Example 1: A general-purpose silicon product processing turntable structure (see attached figure 1 , attached figure 2 , attached image 3 ), including a turntable 1, a plurality of vacuuming grooves 2 are arranged on the upper surface of the turntable at radial intervals, a suctioning hole 3 is arranged in the vacuuming groove, and a ventilation interface 4 is arranged in the middle of the turntable, and the suctioning holes are connected with the ventilation interface. The vacuuming groove is of annular structure, the turntable is provided with a plurality of fixture fixing holes 5 arranged at radial intervals, and the fixture fixing holes are provided with several circles. The upper surface of the turntable is a plane structure. Two air extraction holes are evenly arranged in each vacuum extraction tank.

[0026] A connecting plate 6 is fastened in the middle of the turntable, and the ventilation interface is arranged on the connecting plate. The connecting plate...

Embodiment 2

[0028] Example 2: A general-purpose silicon product processing turntable structure (see attached Figure 4 ), its structure is the same as that of Embodiment 1, the main difference is that in this embodiment, the turntable includes a disc base 15 and a plurality of disc bodies 16 mounted on the disc base. The vacuum groove is provided on the upper surface of the disc body. The disc base and the disc body are provided with radially arranged slide rails 17 , and the disc body and the slide rail are provided with slide grooves correspondingly, and the slide grooves are adapted and connected to the slide rails. A locking screw 18 is installed on the disc body, and the locking screw abuts on the slide rail. A connecting plate is fastened in the middle of the plate seat, the ventilation interface is arranged on the connecting plate, the slide rail is provided with a guide hole, the connecting plate and the slide rail are provided with a number of communication holes one by one, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com