Material box warehousing method, equipment, medium and product

A material box and warehouse technology, applied in the field of material box storage methods, equipment, media and products, can solve the problems that affect the efficiency of material box delivery, affect the efficiency of storage delivery, etc., achieve reasonable and efficient storage of material boxes, and reduce travel effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

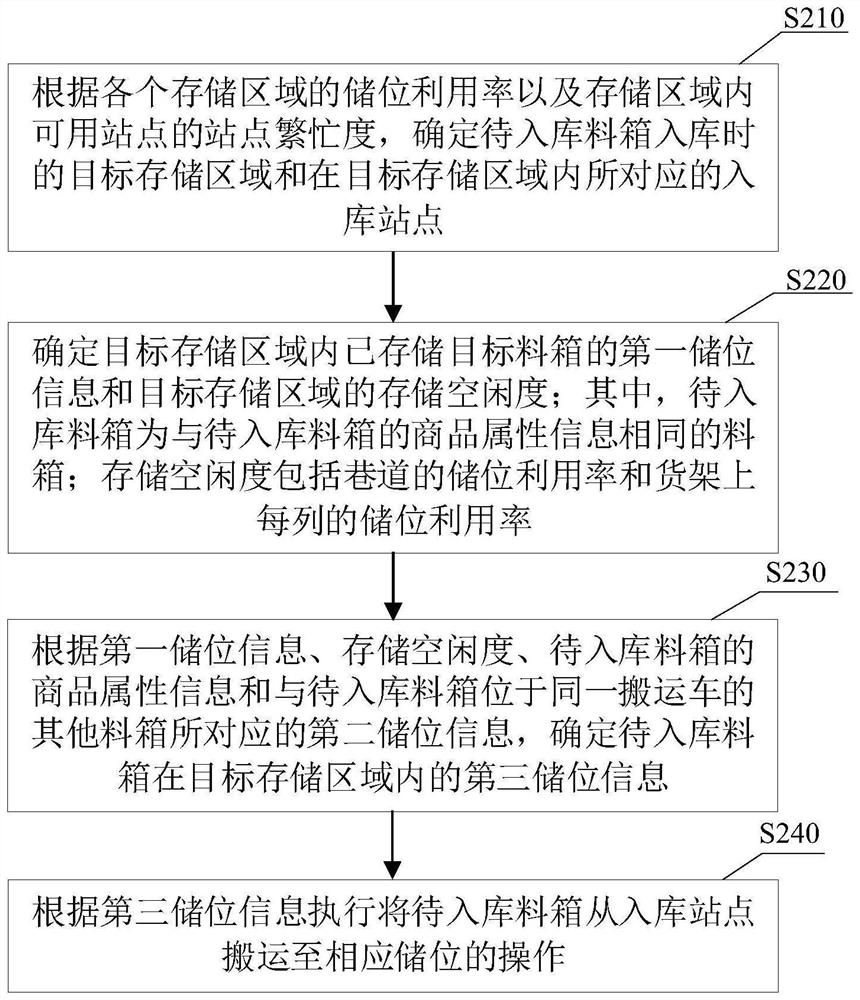

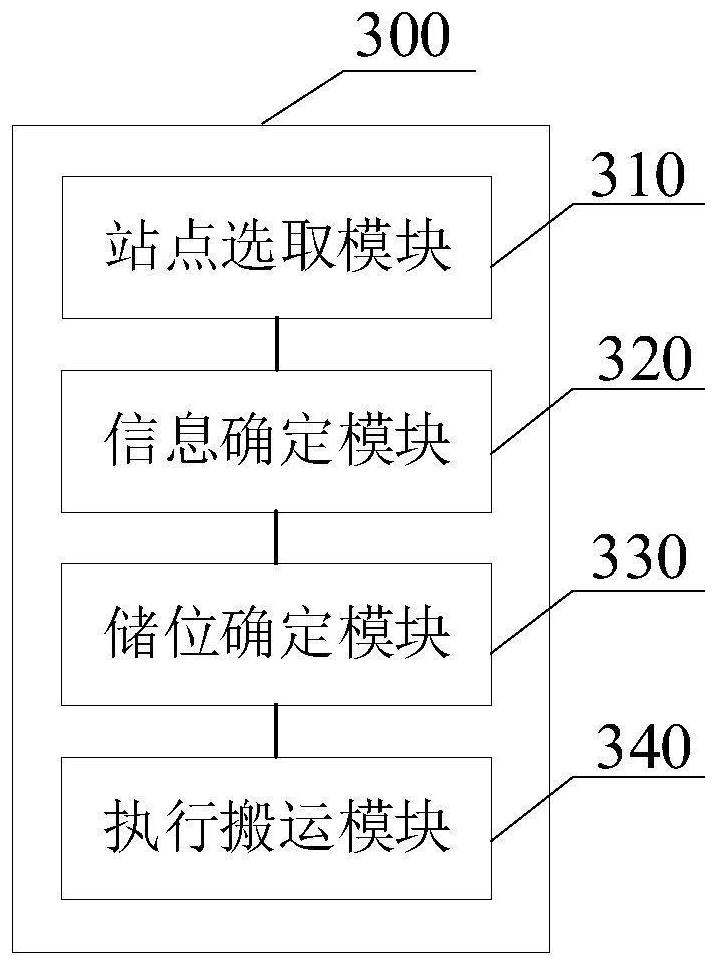

Method used

Image

Examples

Embodiment 1

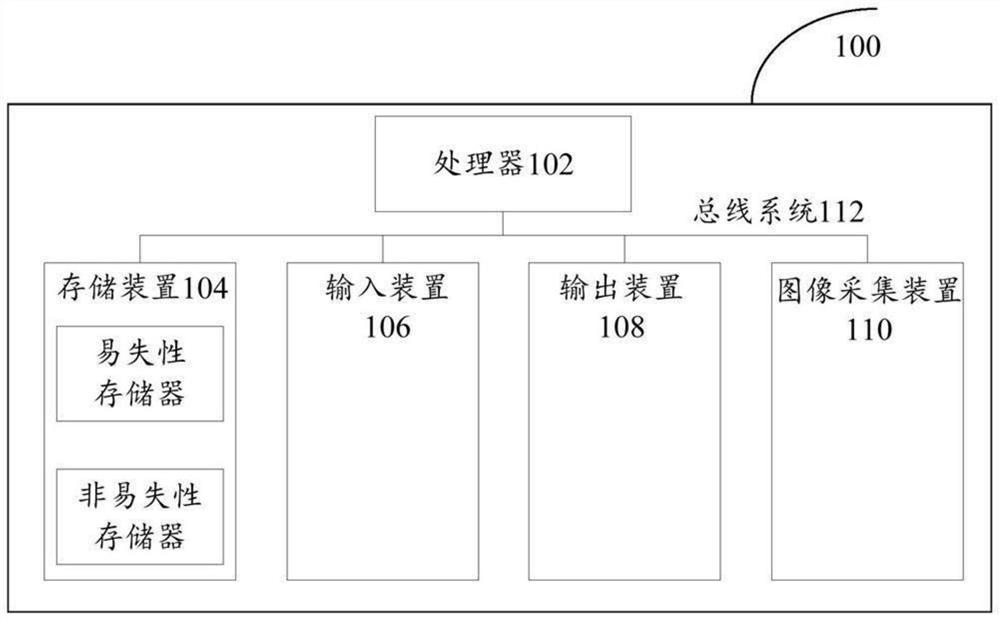

[0059] First, refer to figure 1 An exemplary electronic device 100 for implementing a bin storage method and a storage system according to an embodiment of the present invention will be described.

[0060] Such as figure 1 Shown is a schematic structural diagram of an electronic device. The electronic device 100 includes one or more processors 102, one or more storage devices 104, an input device 106, an output device 108, and an image acquisition device 110. These components pass through a bus system 112 and / or other forms of connection mechanisms (not shown). It should be noted that figure 1 The components and structure of the electronic device 100 shown are only exemplary, not limiting, and the electronic device may also have other components and structures as required.

[0061] The processor 102 can be implemented in at least one hardware form of a digital signal processor (DSP), a field programmable gate array (FPGA), and a programmable logic array (PLA), and the proce...

Embodiment 2

[0068] With the development of intelligent technologies such as the Internet of Things, artificial intelligence, and big data, the demand for using these intelligent technologies to transform and upgrade the traditional logistics industry has become increasingly strong, and intelligent logistics (Intelligent Logistics System) has become a research hotspot in the field of logistics. Smart logistics uses artificial intelligence, big data, various information sensors, radio frequency identification technology, global positioning system (GPS) and other Internet of Things devices and technologies, and is widely used in basic logistics such as material transportation, warehousing, distribution, packaging, loading and unloading, and information services. The activity link realizes the intelligent analysis and decision-making, automatic operation and high-efficiency optimized management of the material management process. The Internet of Things technology includes sensing equipment, RF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com