Temperature control system and temperature control method for flowing working medium

A temperature control system and mobile technology, which can be applied to the operation mode of the machine, the machine using the electromagnetic/magnetic effect, the compressor machine with reversible cycle, etc., which can solve the problems of temperature sensitivity and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

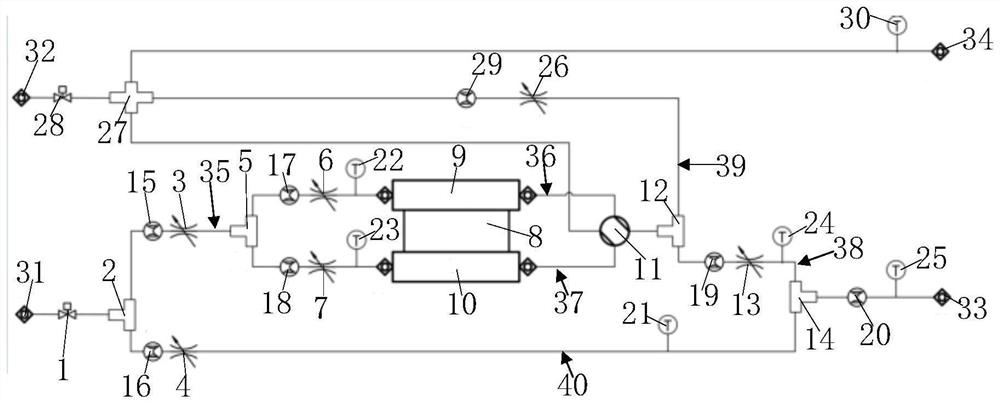

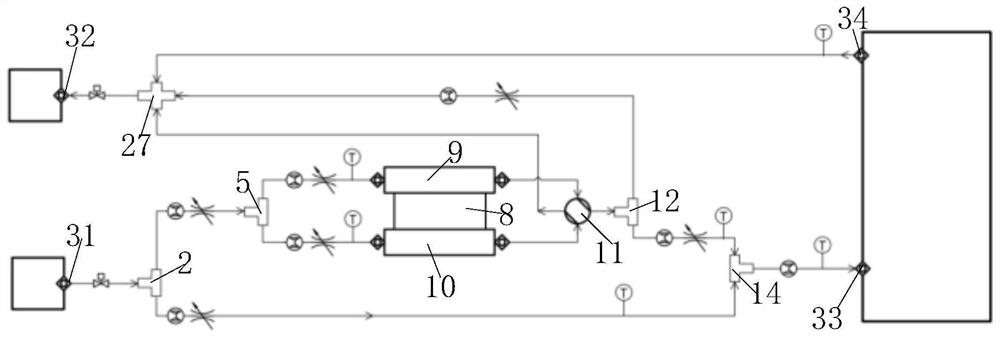

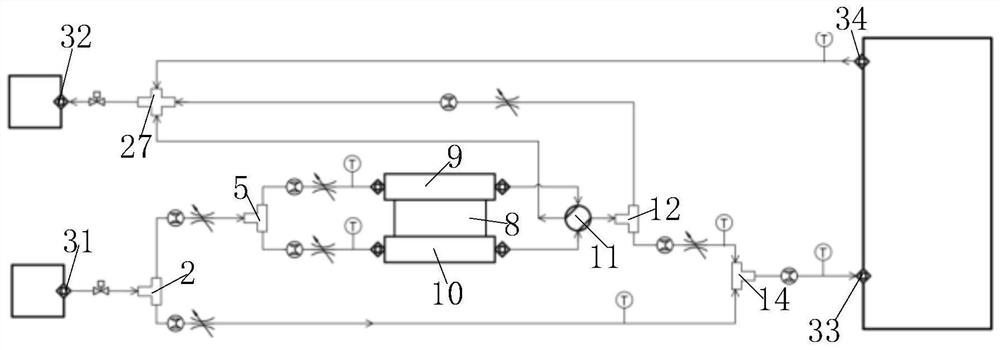

[0049] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0050] like Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a temperature control system for flowing working fluid, which includes: a first flow regulating branch 35 , a first temperature control branch 36 and a second temperature control branch 37 . The upstream pipelines of the first temperature control branch 36 and the second temperature control branch 37 are respectively communicated with the first flow regulating branch 35 through the second water diversion tee 5, and the first temperature control branch 36 and the second The downstream pipelines of the temperature control branch 37 are respectively connected to the four-way switching valve 11, and communicate with the liquid supply port 33 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com