Pipeline mounting bracket capable of saving building floor height

A pipeline installation and building layer technology, applied in the direction of pipeline supports, sustainable buildings, pipes/pipe joints/fittings, etc., can solve the problems of occupying usable building space, wasting building space, occupying usable space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

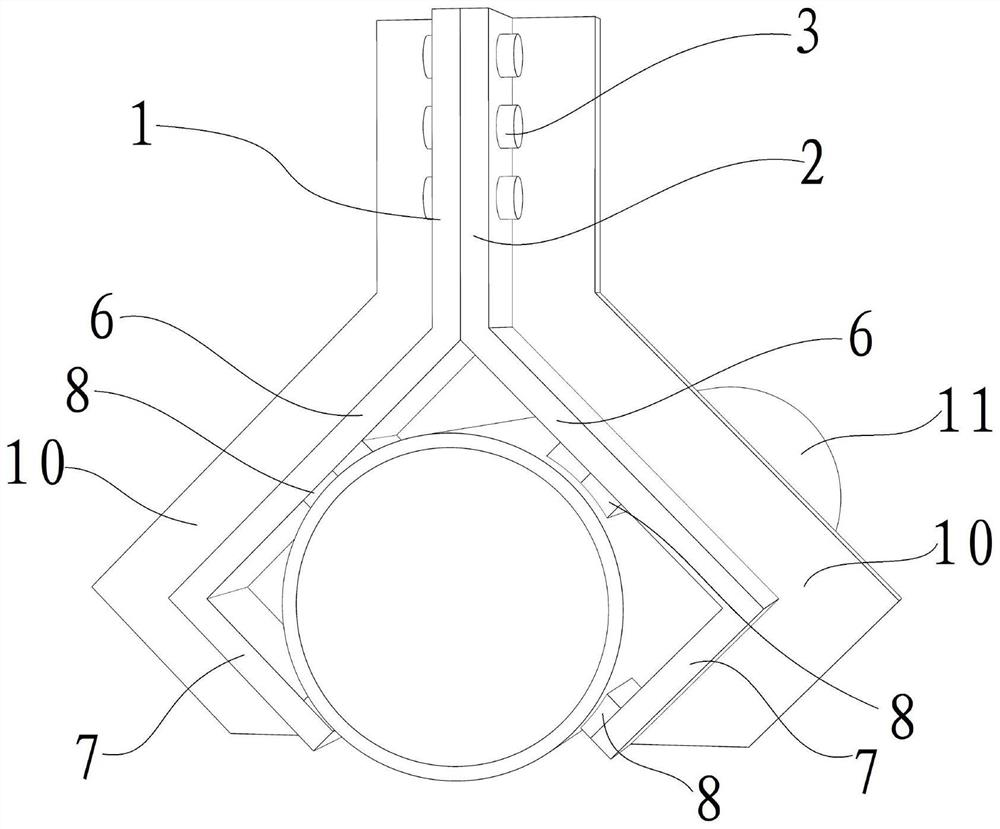

[0037] Such as figure 1 , figure 2 As shown, in this embodiment, a connecting frame A1 and a connecting frame B2 are included, and the connecting frame A1 and the connecting frame B2 are fixedly connected by a connecting fixture 3. In this embodiment, the connecting fixture 3 adopts Bolts and nuts are convenient for the installation and disassembly of the connecting frame A1 and the connecting frame B2, and the tops of the connecting frame A1 and the connecting frame B2 are fixedly connected with the building structure by means of a ceiling bracket or an anti-seismic bracket (by a ceiling bracket or The connection between the anti-seismic support and the building is a conventional technical means in the art, and its specific structure is not described in detail here), the bottom end of the connecting frame A1 is fixedly provided with a pipe clamp A4, and the bottom end of the connecting frame B2 is fixed A pipe clamp B5 is provided, the connecting frame A1 and the pipe clamp...

Embodiment 2

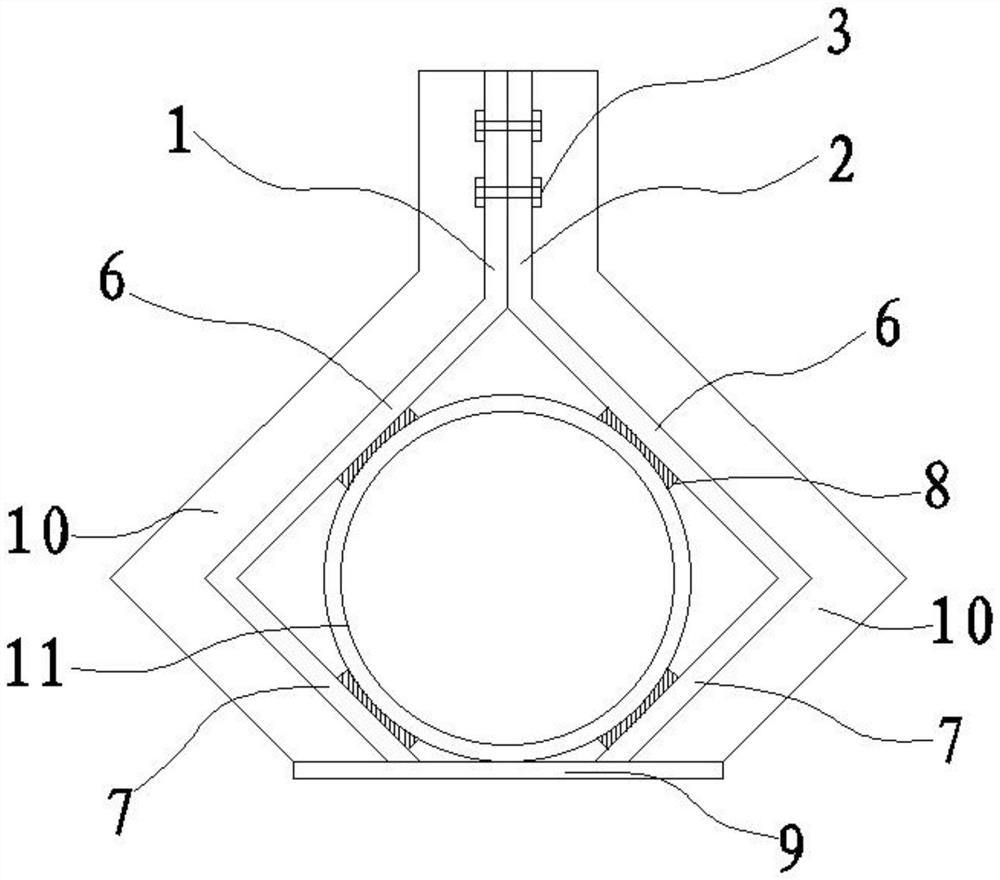

[0043] Such as image 3 As shown, when the pipeline is heavy, in order to improve the clamping strength of the pipeline 11, this embodiment adds the following technical solution on the basis of the third embodiment: the bottom ends of the pipe clamp A4 and the pipe clamp B5 pass through the reinforcement connector 9 Fixed connection, that is, the bottom ends of the two second holding sections 7 are fixedly connected through the reinforcement connector 9 to improve the clamping strength of the pipeline 11. Specifically, the reinforcement connector 9 can use a connecting plate or a linear steel The connecting plate can be fixedly connected with the pipe clamp A4 and the pipe clamp B5 by welding, bolting or riveting, and the pipe clamp A4 and the pipe clamp B5 can be fixedly connected through the reinforced connecting frame, so as to limit the pipe clamp A4 and the pipe clamp B5. The clamp B5 is opened to both sides to ensure the strength and stability of clamping the pipeline 11...

Embodiment 3

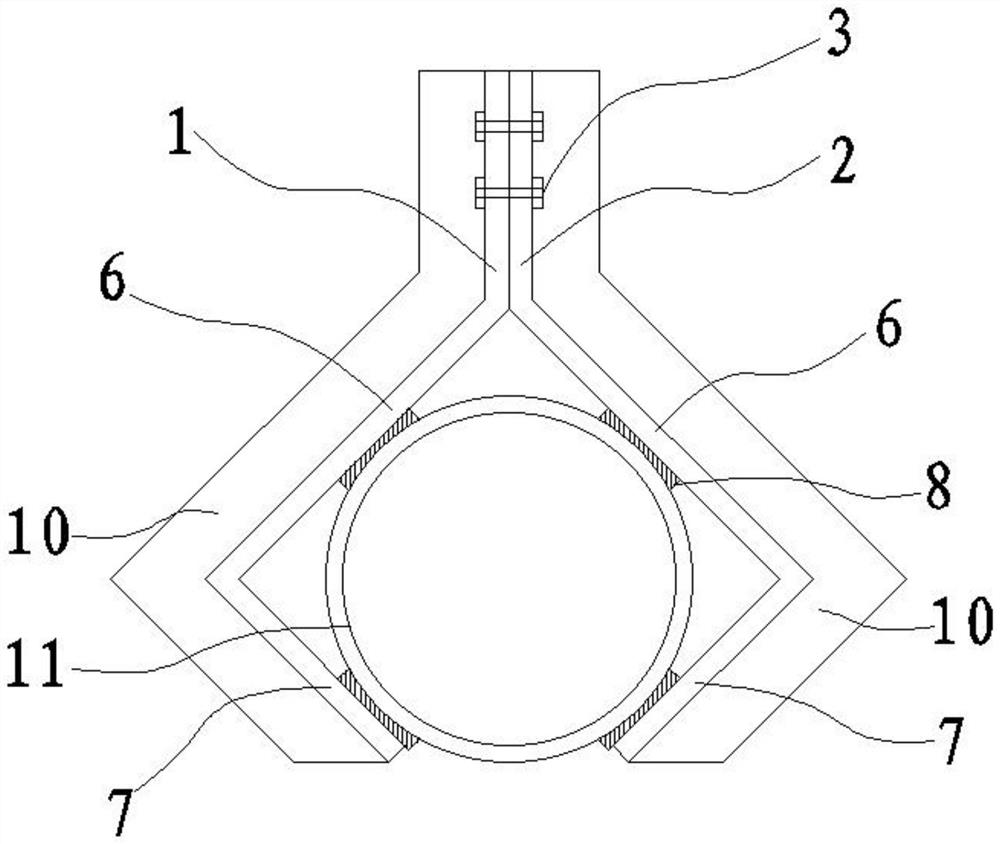

[0045] Such as Figure 4 As shown, in this embodiment, a connecting frame A1 and a connecting frame B2 are included, and the connecting frame A1 and the connecting frame B2 are fixedly connected by a connecting fixture 3. In this embodiment, the connecting fixture 3 adopts Bolts and nuts are convenient for the installation and disassembly of the connecting frame A1 and the connecting frame B2, and the tops of the connecting frame A1 and the connecting frame B2 are fixedly connected with the building structure by means of a ceiling bracket or an anti-seismic bracket (by a ceiling bracket or The connection between the anti-seismic support and the building is a conventional technical means in the art, and its specific structure is not described in detail here), the bottom end of the connecting frame A1 is fixedly provided with a pipe clamp A4, and the bottom end of the connecting frame B2 is fixed A pipe clamp B5 is provided, the connecting frame A1 and the pipe clamp A4 are inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com