Extruder and production process thereof

A technology of extruder and machine body, which is applied in the field of extruder and its production process, can solve problems such as clogging of hoppers, and achieve the effect of avoiding overheating of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

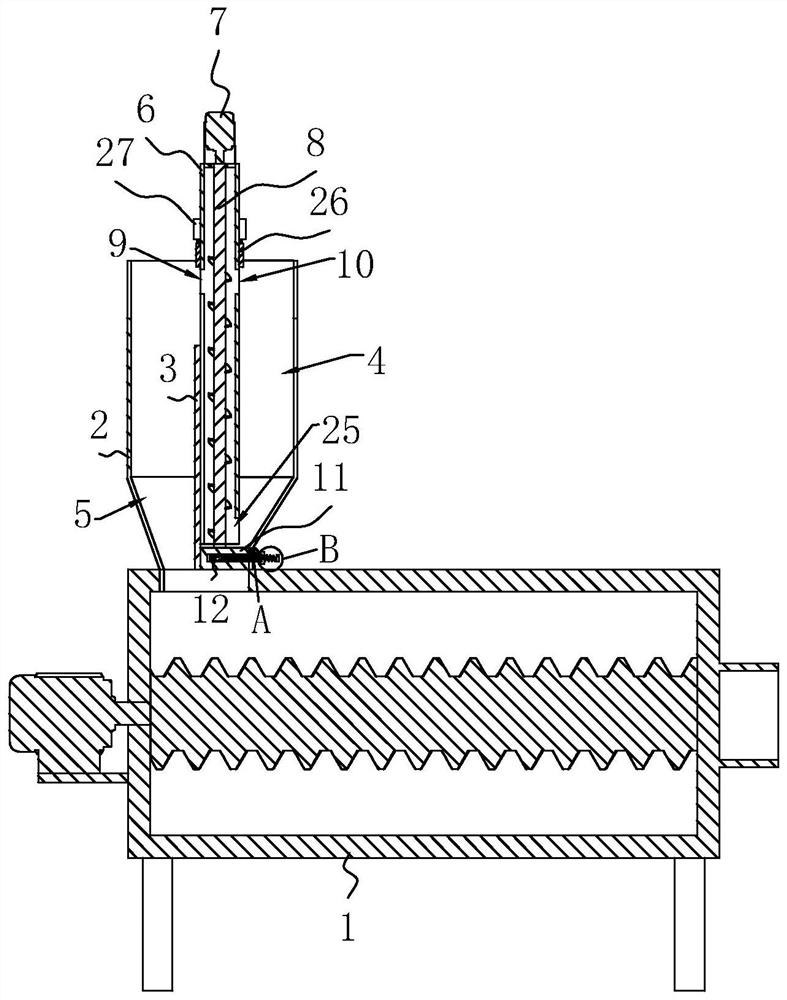

[0042] The embodiments of the present application disclose an extruder and a production process thereof. refer to figure 1 , an extruder and its production process include a body 1 and a hopper 2 installed on the body 1, the hopper 2 is fixedly connected with a dividing plate 3, the dividing plate 3 is located on the vertical symmetry plane of the hopper 2, and the hopper 2 is in The two sides of the dividing plate 3 respectively form a circulation area 4 and a feeding area 5. The dividing plate 3 is fixedly connected with a material barrel 6, the material barrel 6 is arranged vertically, and the material barrel 6 is provided with a reciprocating motion structure for material circulation, Both sides of the top of the barrel 6 are respectively provided with a circulation port 10 and a feed port 9, the circulation port 10 is set towards the circulation zone 4, and the feed port 9 is set towards the feed zone 5;

[0043] refer to figure 1 , the barrel 6 is provided with a contr...

Embodiment 2

[0053] The embodiment of the present application discloses a production process of an extruder. refer to figure 1 , a production process of an extruder comprises the steps,

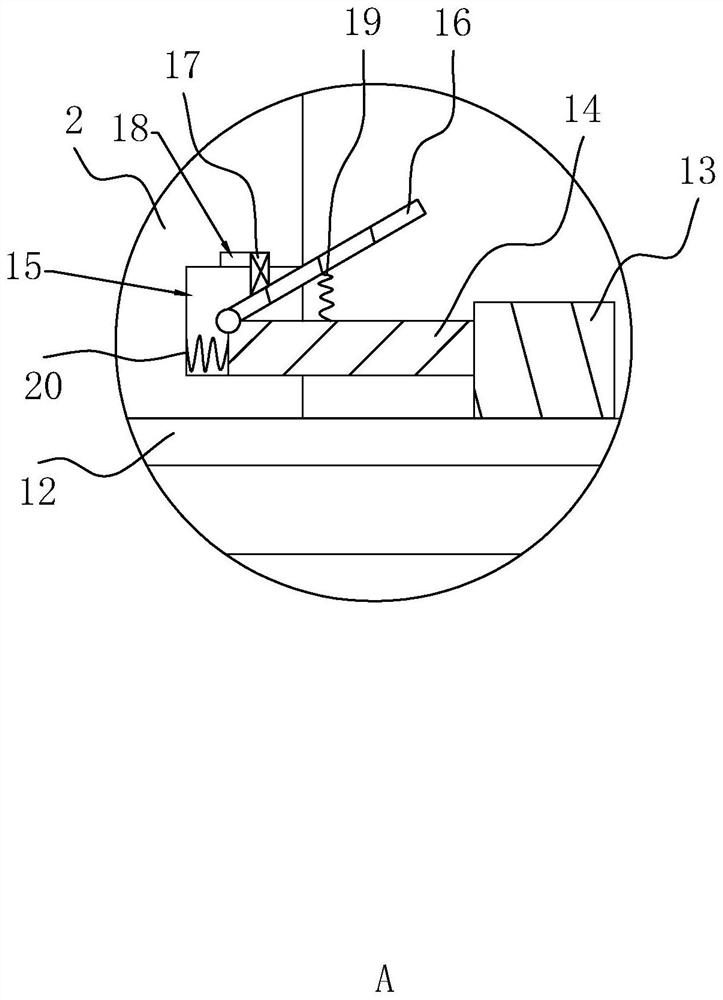

[0054] S1. Install the cooling pipe 12, insert the cooling pipe 12 with the ice strip into the cooling plate 11, and fix the cooling pipe 12; place the ice strip in the cooling pipe 12, and connect the sealing cover 21 to the cooling pipe 12 Thread connection, insert the plug-in block 14 into the plug-in hole 15, the plug-in block 14 is inserted into the plug-in hole 15, and under the cooperation of the clamping piece 16 and the first spring 19, the convex block 17 moves to In the groove 18, the clamping effect of the plug-in block 14 is realized, and the fixing effect of the cooling pipe 12 is completed;

[0055] S2, material circulation, using the cooperation of the control board 26 and the air cylinder 27, open the circulation port 10 and close the feed port 9, load the material into the circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com