Small product multi-surface machining device and machining method

A multi-faceted processing and product technology, applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of multiple clamping times and high cost, and achieve the effect of simple operation, low processing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

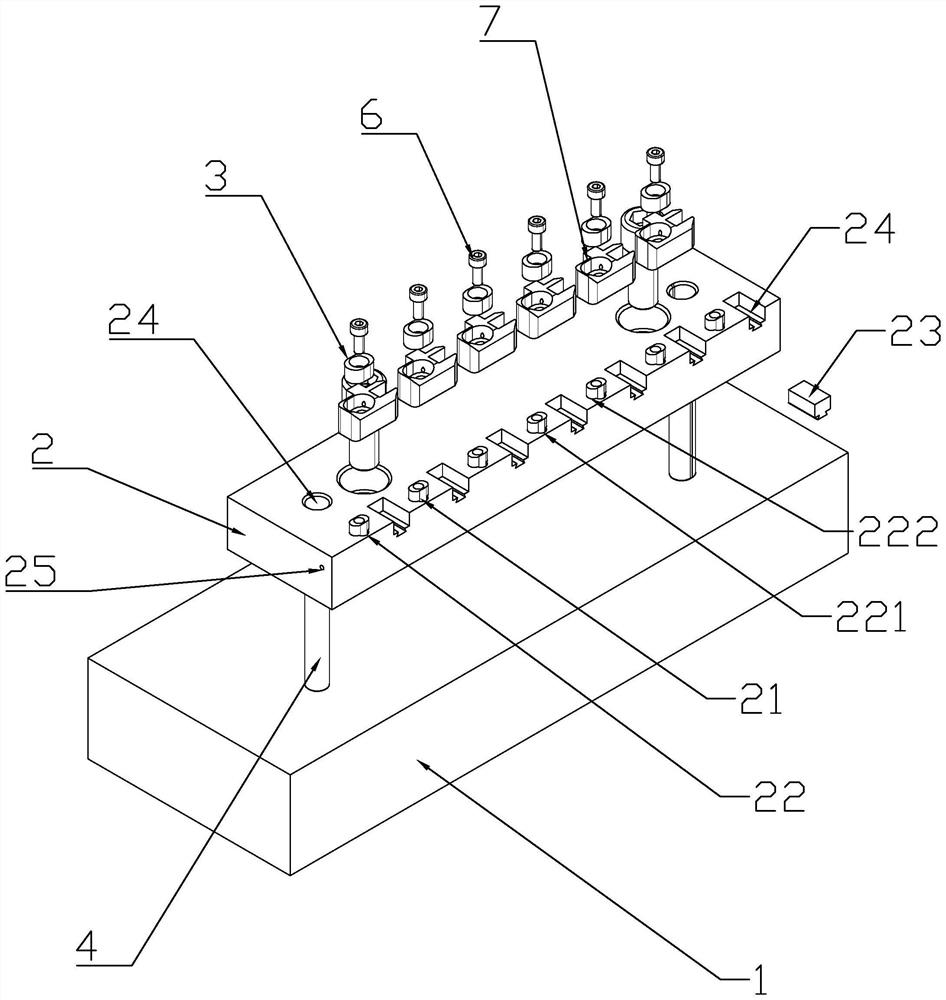

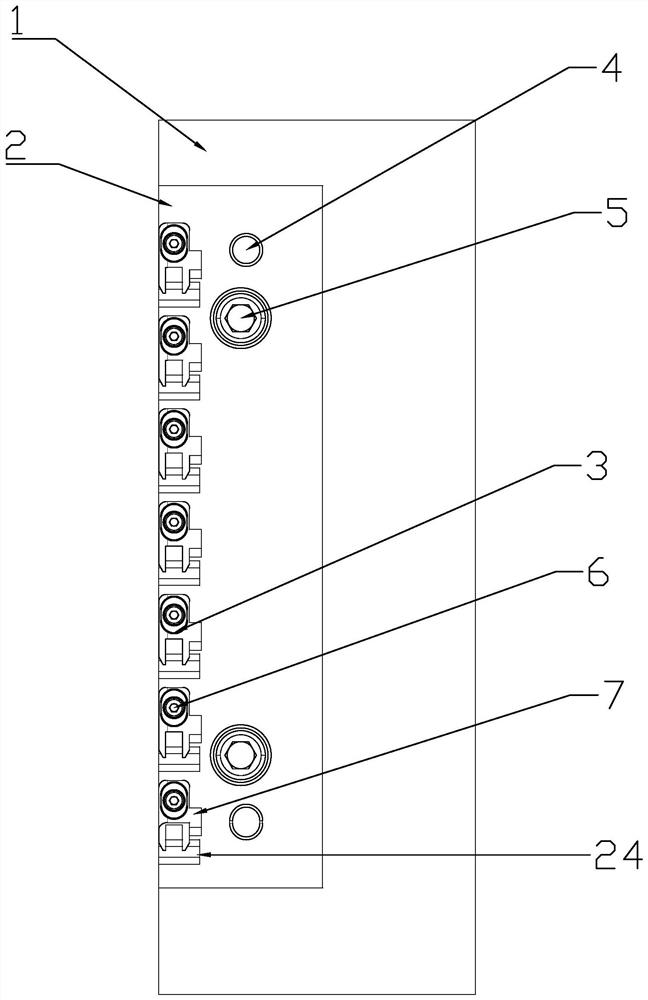

[0036] like figure 1 , figure 2 As shown in the figure, a multi-faceted processing device for small products includes a positioning plate 1, a rectangular parallelepiped body 2 and a plurality of fixed bodies 3. The fixed body 3 is inserted and matched with the top surface of the product, and the fixed body 3 is provided with a through hole. The assembly is detachably connected to the positioning plate 1. The positioning assembly includes two positioning pins 4 and two fixing bolts 5. The positioning pins 4 are vertically arranged on the positioning plate 1, and the mother body 2 is provided with positioning holes adapted to the positioning pins 4. 24. The fixing bolts 5 fix the mother body 2 on the positioning plate 1. The positioning components are arranged symmetrically along the midline.

[0037] The main body 2 is provided with a plurality of vertically arranged slots 22. The cross-section of the slots 22 is waist-shaped. The shape of the second slot 222 is the same. ...

Embodiment 2

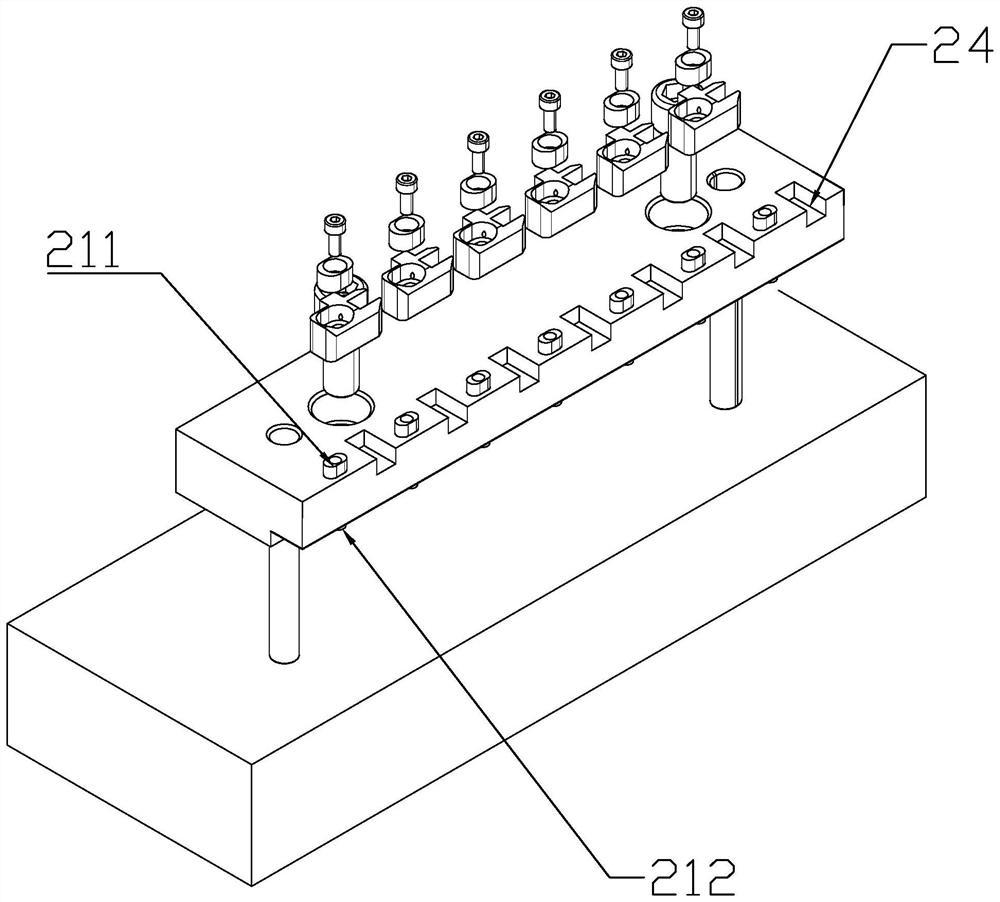

[0045] like image 3 As shown, a multi-faceted processing device for small products is different from Embodiment 1 in that two sets of positioning protrusions 21 are provided on the mother body 2, and the two sets of positioning protrusions 21 are respectively fixed on the upper and lower surfaces of the mother body 2. The two sets of positioning protrusions 21 are vertically arranged. The front side of the mother body 2 is respectively provided with machining avoidance grooves 24 corresponding to a group of positioning protrusions 21 .

[0046] The difference between the method and Example 1 is that,

[0047] In step S1, the mother body 2 is turned over according to the processing surface of the product to ensure that the proper positioning protrusions 21 are set upward.

[0048] By turning the mother body 180°, the processing of different positions and surfaces can be realized, and the side surface with the positioning protrusion with a suitable angle is set upward, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com