Cutting device for viscous energetic material with random size

A cutting device, a sticky technology, used in plastic recycling, metal processing, grain processing, etc., can solve problems such as requirements, and achieve the effect of easy maintenance, low operation difficulty, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below with reference to the accompanying drawings.

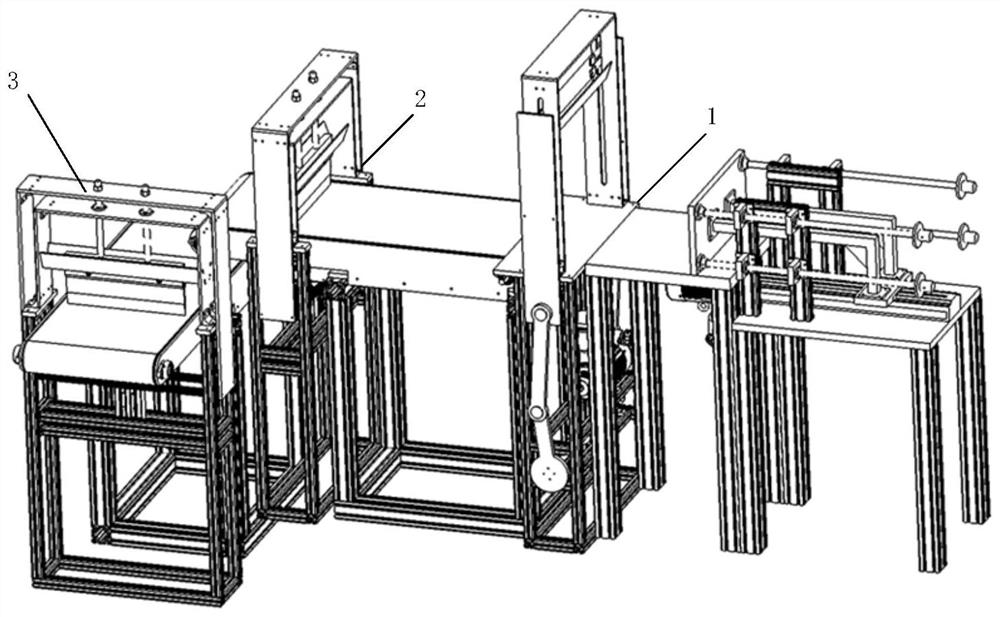

[0046] as attached figure 1 As shown, the cutting device consists of a primary cutting mechanism 1 , a secondary cutting mechanism 2 and a tertiary cutting mechanism 3 .

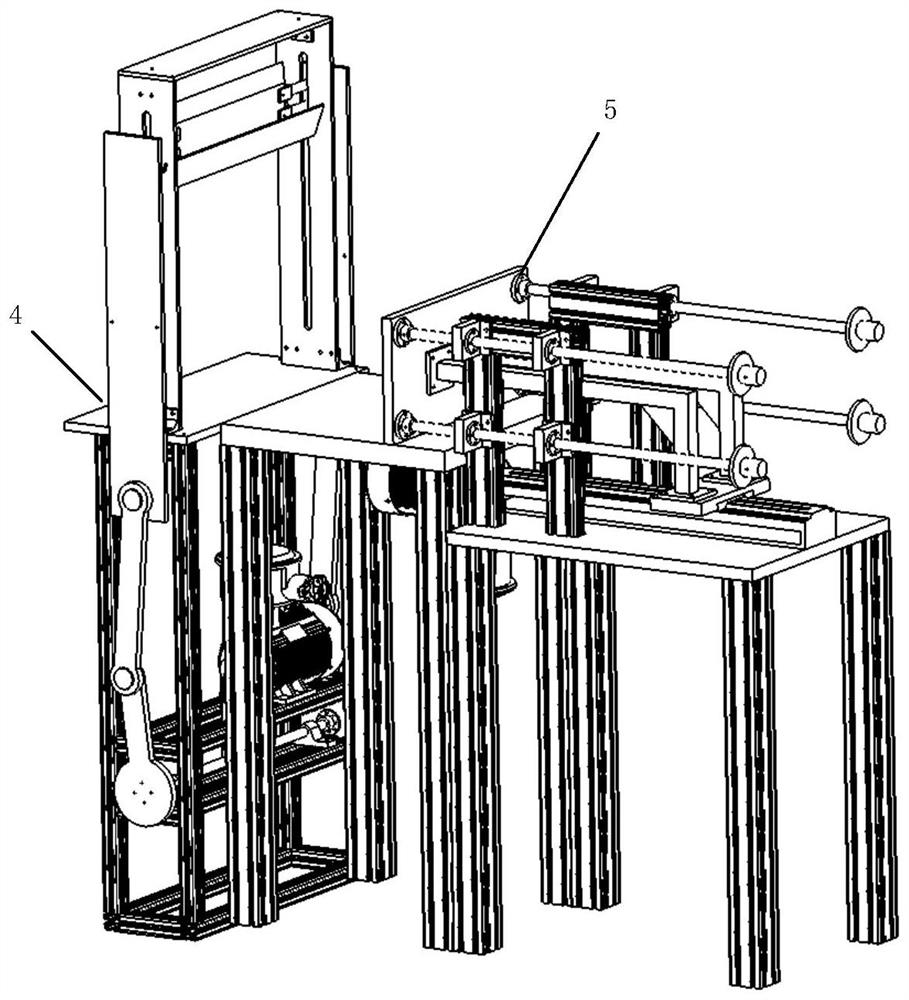

[0047] as attached figure 2 As shown, the primary cutting mechanism 1 is composed of a primary cutter mechanism 4 and a pushing mechanism 5 .

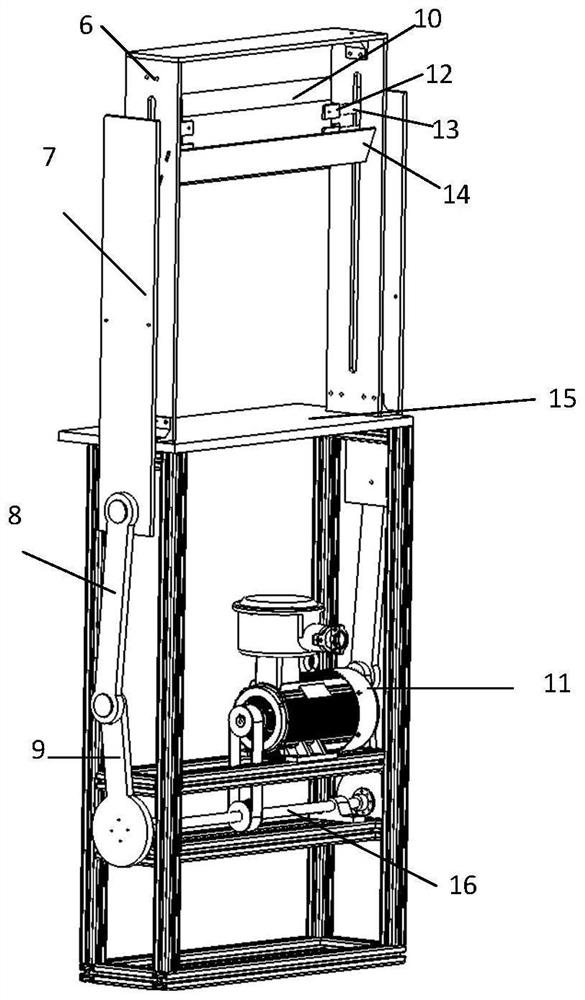

[0048] as attached image 3As shown, the primary tool mechanism 4 is composed of a primary tool guide 6, a primary blade 10, a primary tool holder 12, a primary tool connecting rod 13, a primary sticking knife baffle 14, a primary tool holder 7, and a connecting rod 8. , a crank 9, a first-level drive motor 11, a first-level sticking knife baffle 14, a cutting table 15 and a rotating shaft 16. The primary blade 10 is connected to the primary tool holder 7 through the primary tool holder 12, the primary tool guide 6 fixes the motion trajectory of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com