Oil film thickness measuring method based on real part of ultrasonic reflection coefficient

A technology of reflection coefficient and oil film thickness, which is applied in the re-radiation of sound waves, radio wave measurement systems, and the use of ultrasonic/sonic/infrasonic waves, etc., to achieve high measurement accuracy and important engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

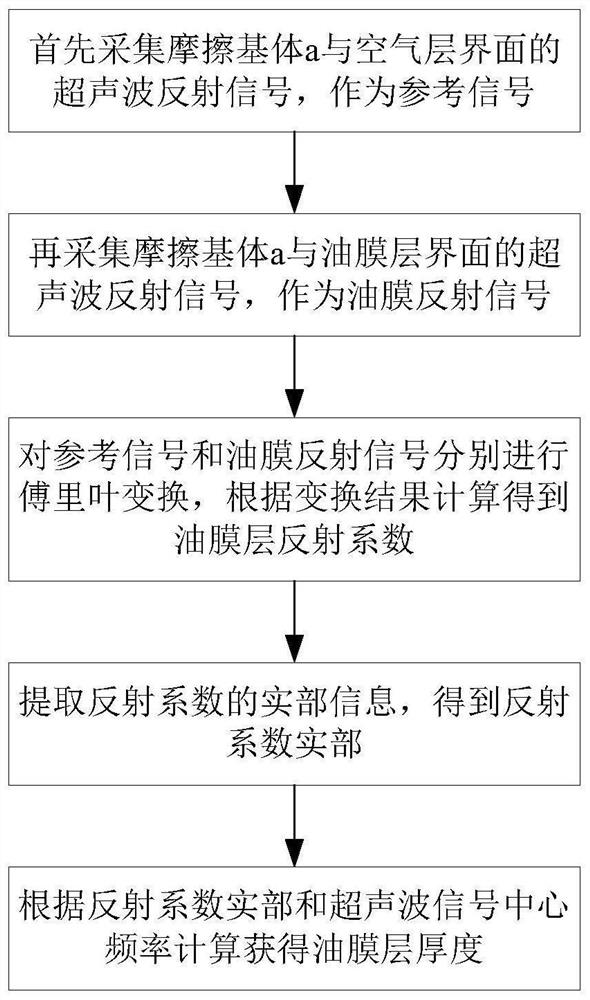

[0040] Specific implementation mode 1. Combination figure 1 and image 3 As shown, the present invention provides a method for measuring oil film thickness based on the real part of the ultrasonic reflection coefficient, comprising:

[0041] The ultrasonic transducer is arranged on the upper surface of the friction substrate a; the pulse transceiver is used to send out periodic pulses to excite the ultrasonic transducer, so that the ultrasonic transducer sends out an ultrasonic signal with a preset width;

[0042] Firstly, the gap between the friction substrate a and the friction substrate b is an air layer, and the ultrasonic reflection signal of the interface between the friction substrate a and the air layer is collected as the reference signal required for calculating the reflection coefficient;

[0043] Then add lubricating oil between the friction substrate a and the friction substrate b to form an oil film layer, and collect the ultrasonic reflection signal at the inte...

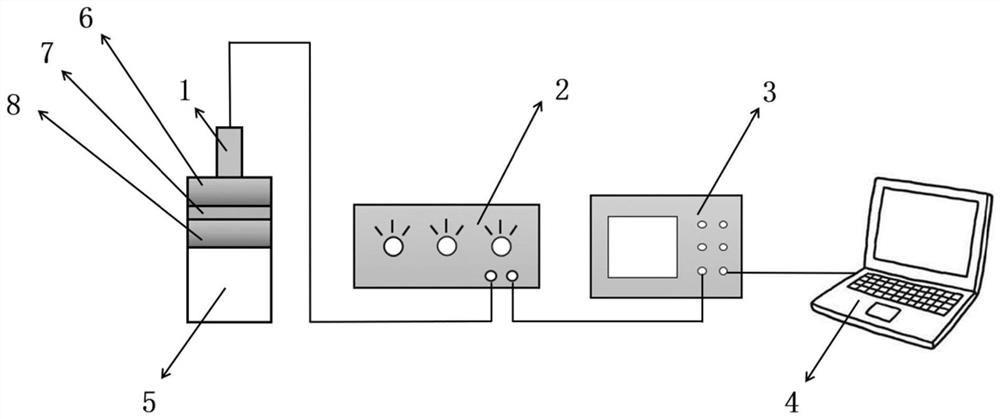

specific Embodiment

[0067] build as image 3 The shown experimental platform for oil film thickness calibration and ultrasonic measurement is used to verify the effectiveness of the method of the present invention. Periodic pulses are sent out by the pulse transceiver 2. After the ultrasonic transducer 1 is excited, an ultrasonic signal is sent out. The ultrasonic signal passes through the substrate a and is emitted at the substrate a-air interface. The reflected signal returns along the original path and is sent to the data acquisition card 3. A recording is made as a reference signal required to calculate the oil film thickness. After the reference signal is measured, a certain amount of lubricating oil is added between the substrate a and the substrate b to form a lubricating oil film. The thickness of the lubricating oil film is changed by the macro-micro composite displacement stage 5, and the reflected signal of the oil film layer is recorded by the data acquisition card 3. Use the comput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com