Fabricated building steel structure lap joint component

A kind of construction steel and assembly technology, applied in the direction of building structure, construction, etc., can solve the problems of inability to quickly and effectively complete structural lap joints, damage to I-shaped steel, and difficulty in disassembly, so as to achieve stable connection, convenient adjustment and disassembly , Improve the effect of reinforcement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

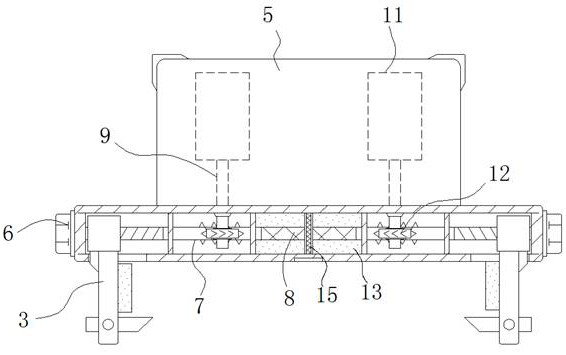

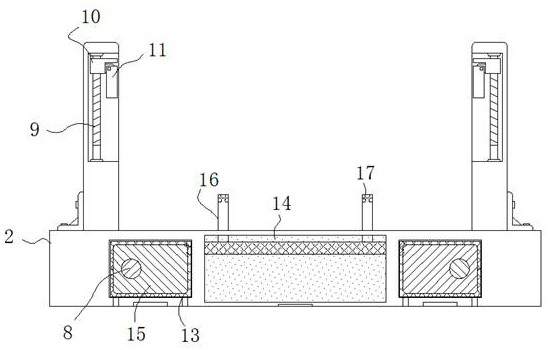

[0047] see Figure 1-7 , the present invention provides a technical solution: a prefabricated building steel structure overlapping member, comprising:

[0048] like Figure 1-2 and Figure 6-7 The technical scheme shown, the I-shaped steel 1, is provided with a positioning plate 2 between the adjacent outer walls of the overlap, and the left and right sides of the bottom of the positioning plate 2 are movably installed with side baffles 3, and the side baffles 3 The lower end is hinged with the limit hook 4, the bottom limit member of the I-shaped steel 1 at the connection between the side baffle 3 and the limit hook 4, is installed and fixed with the edge plate 5 on the top front and rear sides of the positioning plate 2, through the side baffle 3 and the movement of the limit hook 4 to laterally press and fix the lower side of the I-shaped steel, and when the side baffle 3 moves its upper structure and squeezes the side of the I-shaped steel, it can also drive the limit ho...

Embodiment 2

[0055] see Figure 1-5 and Figure 8-9 , the present invention provides a technical solution: a prefabricated building steel structure overlapping member, comprising:

[0056] like Figure 1-2 and Figure 8-9 The technical scheme shown, the I-shaped steel 1, is provided with a positioning plate 2 between the adjacent outer walls of the overlap, and the left and right sides of the bottom of the positioning plate 2 are movably installed with side baffles 3, and the side baffles 3 The lower end is hinged with the limit hook 4, the bottom limit member of the I-shaped steel 1 at the connection between the side baffle 3 and the limit hook 4, is installed and fixed with the edge plate 5 on the top front and rear sides of the positioning plate 2, through the side baffle 3 and the movement of the limit hook 4 to laterally press and fix the lower side of the I-shaped steel, and when the side baffle 3 moves its upper structure and squeezes the side of the I-shaped steel, it can also d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com