Substrate baking device

A technology for baking devices and substrates, applied in printing devices, semiconductor devices, printing and other directions, can solve the problems of high expansion speed of the lower surface, affecting the baking effect of the substrate, and poor heating, so as to avoid warping and improve the baking effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The main body of this embodiment is a substrate baking device, which is applied to the baking process of the substrate 30 after the substrate 30 is deposited by solution deposition. It should be noted here that the apparatus for baking the substrate 30 provided in this embodiment can be used for the baking process of the substrate 30 after the solution deposition method, and can also be used for other baking processes.

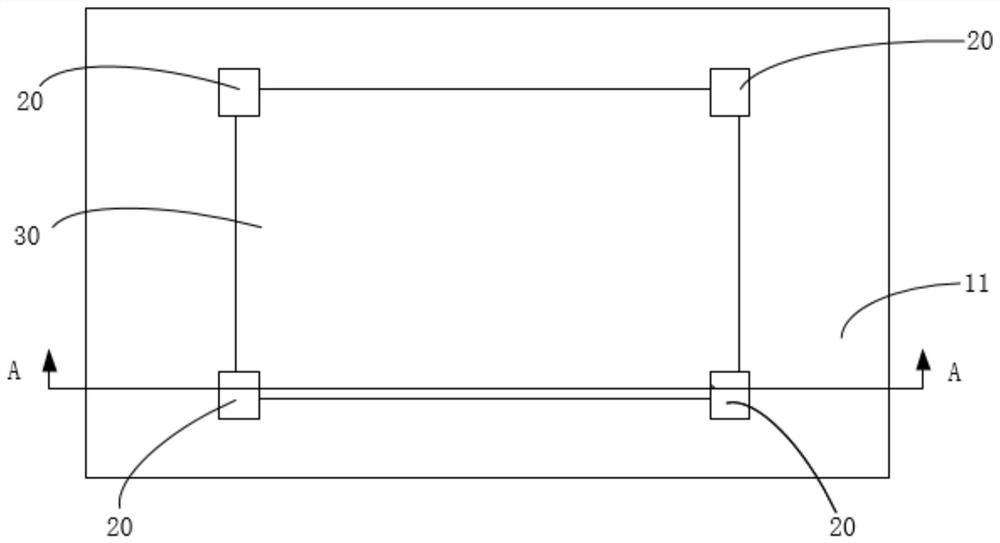

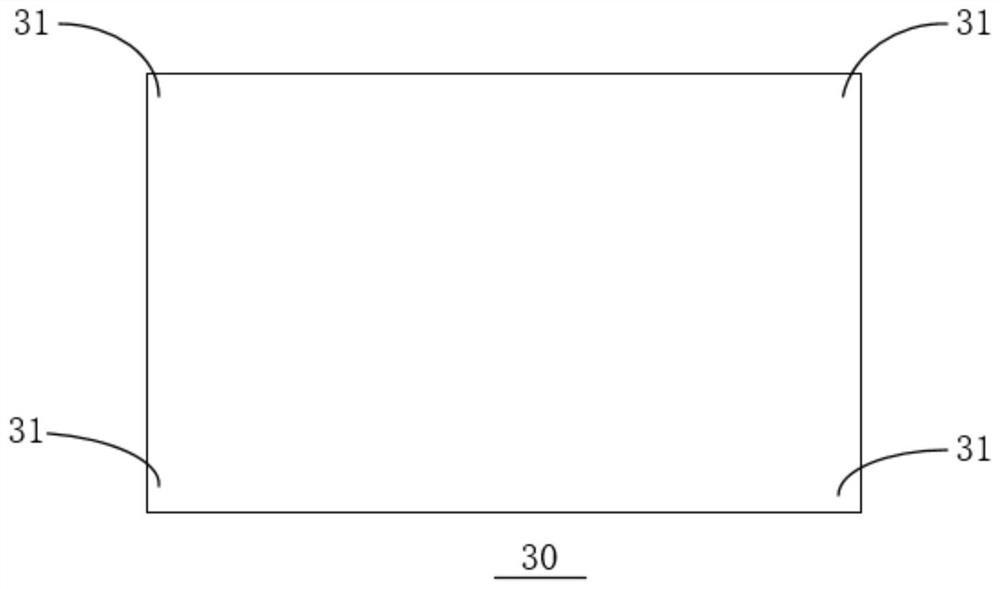

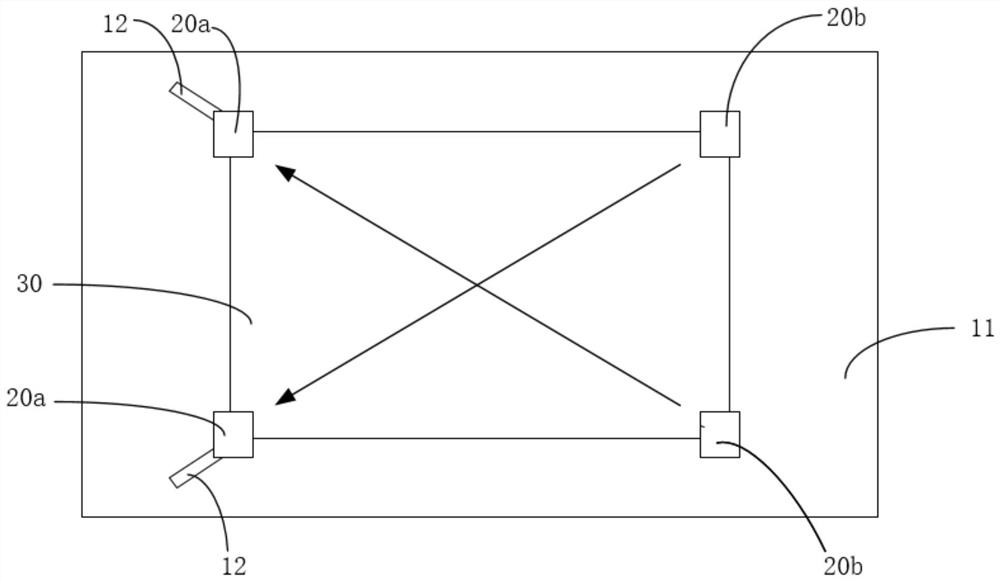

[0037] See figure 1 , image 3 and Figure 4 , in this embodiment, the substrate 30 baking device includes:

[0038] the heating table 10, the heating table 10 is formed with a heating surface 11 for carrying the heating surface 32 of the substrate 30;

[0039]The fixing mechanism is used to limit the relative displacement of at least one corner 31 of the substrate 30 and the heating table 10 in a direction perpendicular to the heating surface 11 when the heating surface 11 supports the substrate 30 .

[0040] Among them, the heating stage 10 mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com