Tobacco leaf curing method based on image acquisition and moisture change

A technology of image acquisition and curing method, which is applied in the fields of tobacco, tobacco processing, analysis of materials, etc., can solve the problems of large curing loss, affecting the drying process, and inaccurate judgment of changes in tobacco leaves, so as to reduce the labor cost of curing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1 This application provides the flue-cured tobacco curing process determined by the method

[0085] Example:

[0086] (1) Baking room

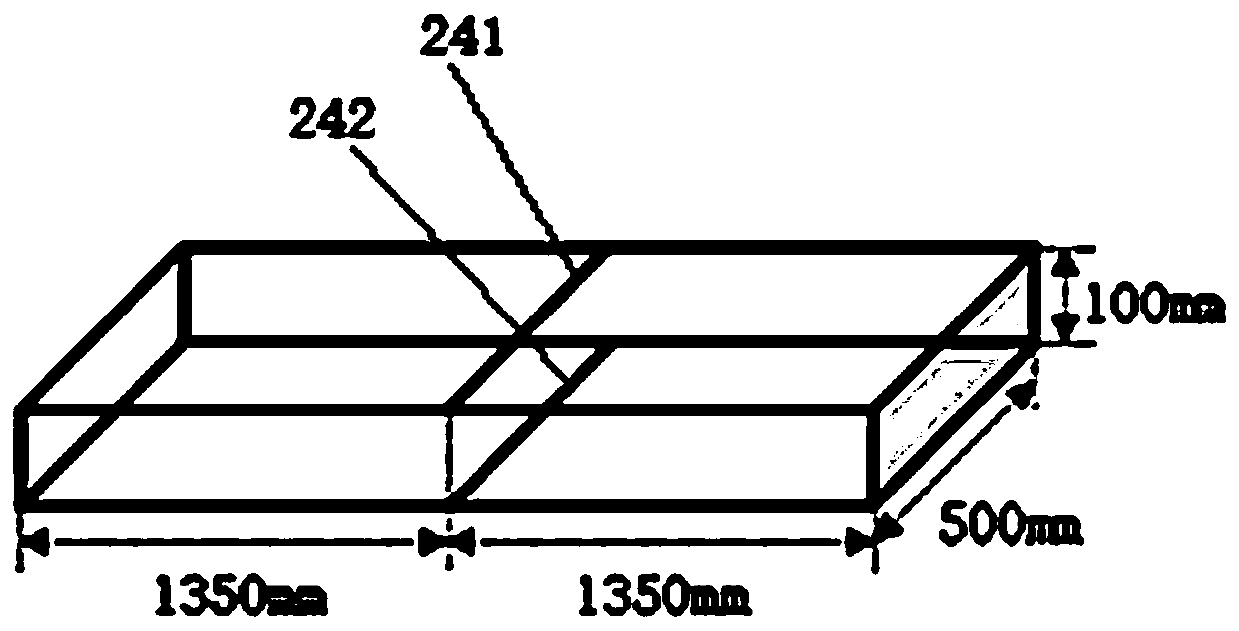

[0087] Choose three horizontal intensive ovens with conventional airflow rising.

[0088] (2) Tobacco leaf image acquisition equipment

[0089]Install 4 sets of image acquisition equipment in the barn. The image acquisition equipment includes camera, image processing module, 4G router and LED warm light. Send the processed image signal back to the information center through the 4G router. Four sets of image acquisition equipment are installed on the middle column of the tobacco hanging beam, and respectively collect images of tobacco leaf tips and leaf bases at the bottom and ceiling of the barn at a position 4 meters away from the door. LED warm lights are respectively installed on the tobacco leaves in the camera photo area.

[0090] Camera: Adopt C35 industrial-grade camera (see figure 1 ), the specific parameters ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com