Composite multifunctional glass and vehicle glass

A multi-functional and multi-functional combined technology, applied to vehicle parts, windshields, glass/slag layered products, etc., can solve problems such as wrinkles or wavy textures, increased edge stress of glass products, splinters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

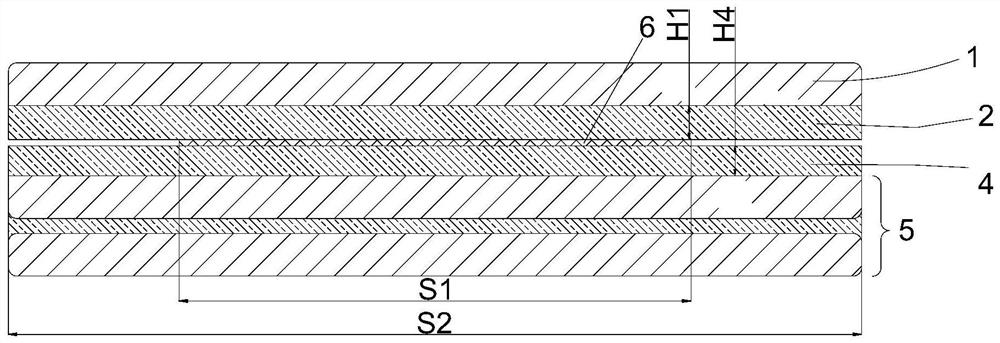

[0053] like figure 1 As shown in the figure, a composite multifunctional glass includes a first glass plate 1 , a first adhesive film layer 2 , a composite multifunctional combined layer 6 , a third adhesive film layer 4 and a second glass plate 5 , which are sequentially stacked from top to bottom. . The area S1 of the composite multifunctional combined layer 6 is smaller than the area S2 of the composite multifunctional glass, and a vacancy that is consistent with or approximately consistent with its thickness H is formed on its periphery.

[0054] Wherein, S1 / S2=0.4, which satisfies S1 / S2≤0.5, and the second adhesive film layer 3 is not provided. The thickness H of the composite multifunctional combined layer 6 is 0.1 mm; the thickness H1 of the first adhesive film layer 2 is 0.76 mm; the vacant height around the composite multifunctional combined layer 6 is 0.1 mm.

[0055] The double curvature of the composite multifunctional glass product is 3000mm. The first adhesive...

Embodiment 2

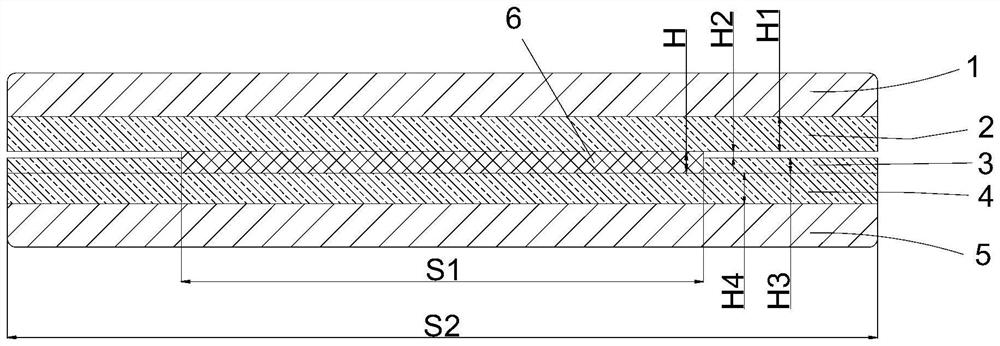

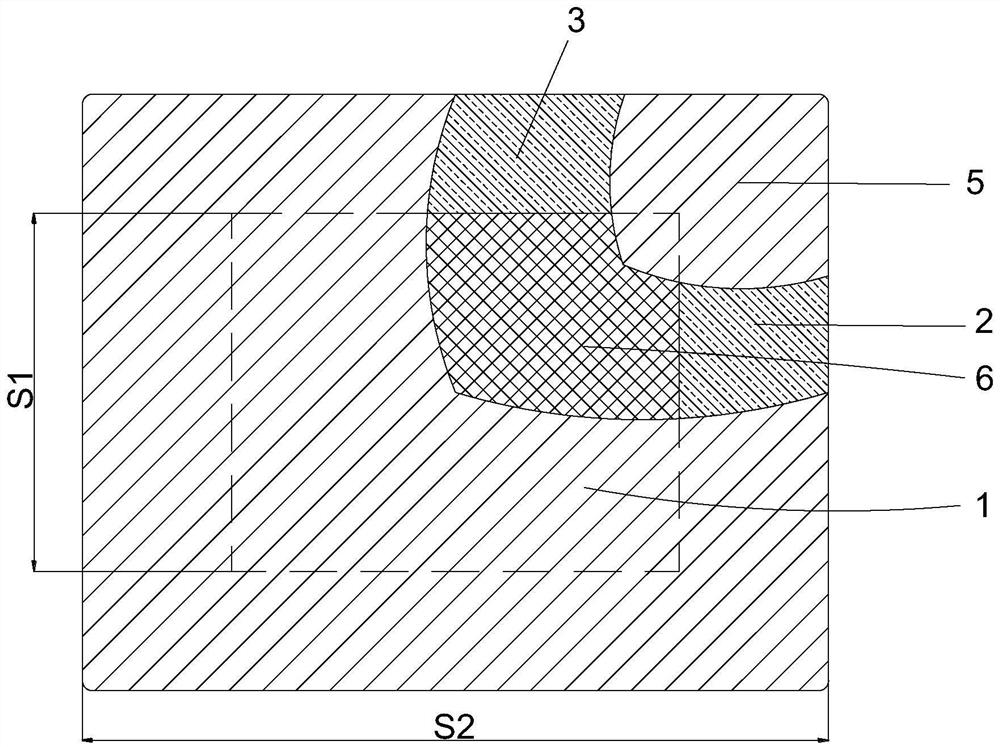

[0058] like figure 2 and image 3 As shown in the figure, a composite multifunctional glass includes a first glass plate 1 , a first adhesive film layer 2 , a composite multifunctional combined layer 6 , a third adhesive film layer 4 and a second glass plate 5 , which are sequentially stacked from top to bottom. .

[0059] The area S1 of the composite multifunctional combined layer 6 is smaller than the area S2 of the composite multifunctional glass, and a vacancy that is consistent with or approximately the same thickness H is formed on the periphery thereof.

[0060] Wherein, S1 / S2=0.6, the thickness H of the composite multifunctional combination layer 6 is 1.0 mm, the thickness H1 of the first adhesive film layer 2 is 0.76 mm, and the thickness H4 of the third adhesive film layer 4 is 0.76 mm.

[0061] Satisfying 0.5 image 3 fills this gap).

[0062] At this time, 0

Embodiment 3

[0066] The differences between the composite multifunctional glass in this embodiment and Embodiment 2 include:

[0067] S1 / S2=0.9, the thickness H of the composite multifunctional combination layer 6 is 0.9 mm, the thickness H1 of the first adhesive film layer 2 is 0.76 mm, and the thickness H4 of the third adhesive film layer 4 is 0.38 mm.

[0068] Satisfy 0.5

[0069] The double curvature of the composite multifunctional glass product is 3300mm. The second adhesive film layer 3 is located on the periphery of the composite multifunctional composite layer 6, and completely fills the area of the composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com