A kind of cutting equipment for motorcycle clutch production mould

A technology of cutting equipment and clutch, which is applied in the direction of metal processing equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of inconvenient cleaning of debris, cumbersome back and forth operation, and inconvenient operation, so as to achieve convenient processing and picking operation The effect of convenience and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

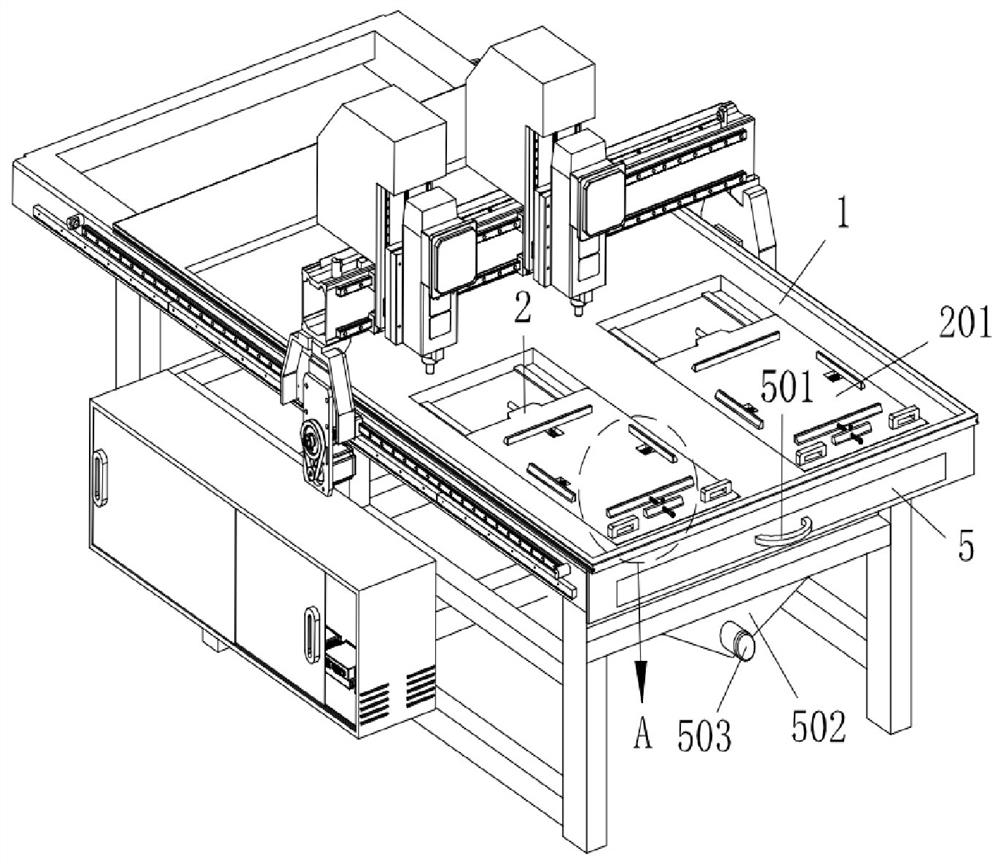

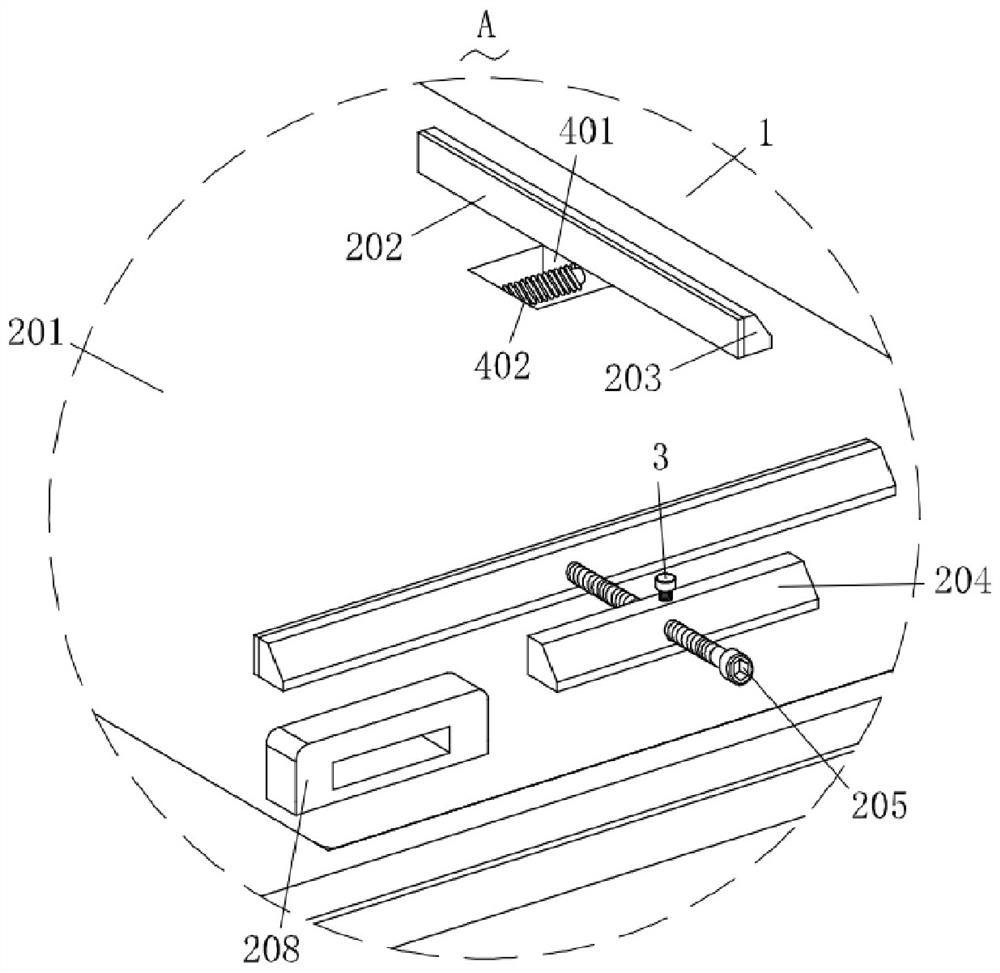

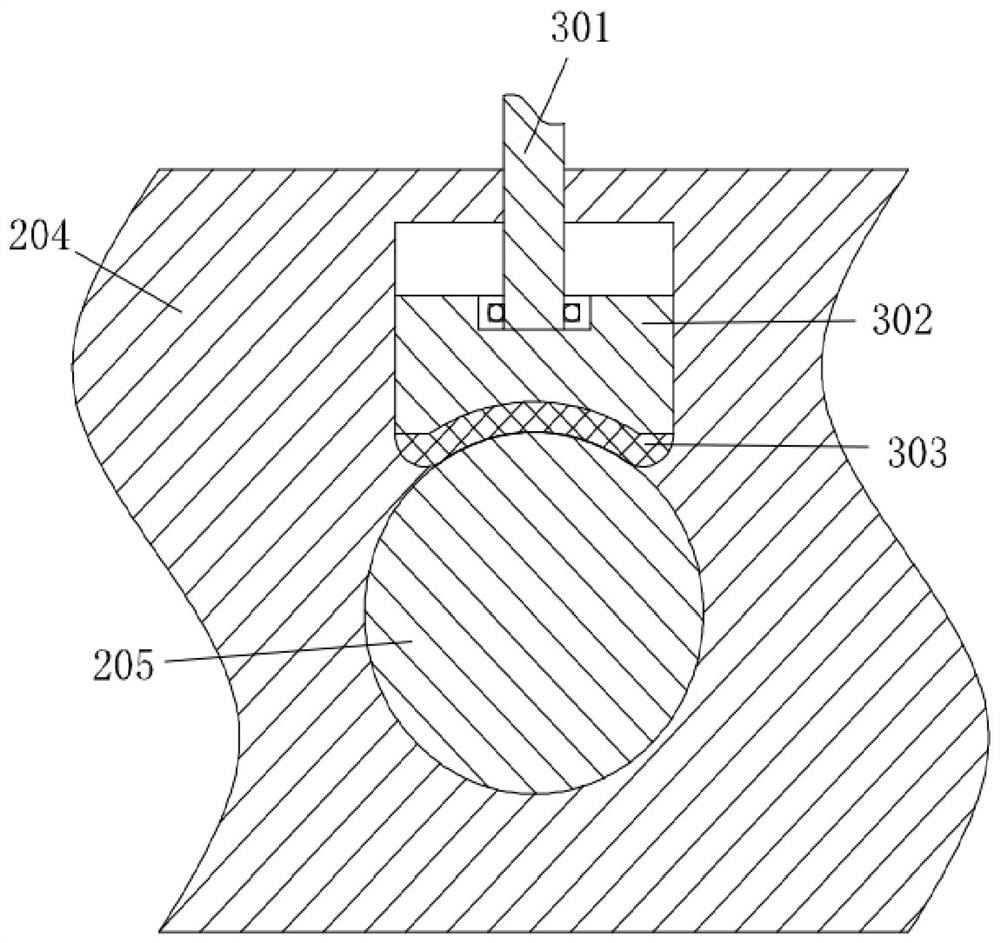

[0030] like Figure 1-Figure 8 As shown, a cutting device for a motorcycle clutch production mold according to the present invention includes a machine tool body 1, on which two placement mechanisms 2 are installed, and a protective mechanism 3 is connected to the placement mechanism 2. , a control mechanism 4 is connected to the placement mechanism 2 , a limit mechanism 6 is installed to the placement mechanism 2 , a cleaning mechanism 5 is installed to the machine tool body 1 , and a locking mechanism 7 is connected to the machine tool body 1 .

[0031] Specifically, the placing mechanism 2 includes a sliding rod 207, two sets of sliding rods 207 are installed on the machine tool body 1, and two placing plates 201 are provided on the machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com