Sand screening device for house building and using method of sand screening device

A technology for building and sieving sand, applied in chemical instruments and methods, sieving, solid separation, etc., can solve problems such as slow work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

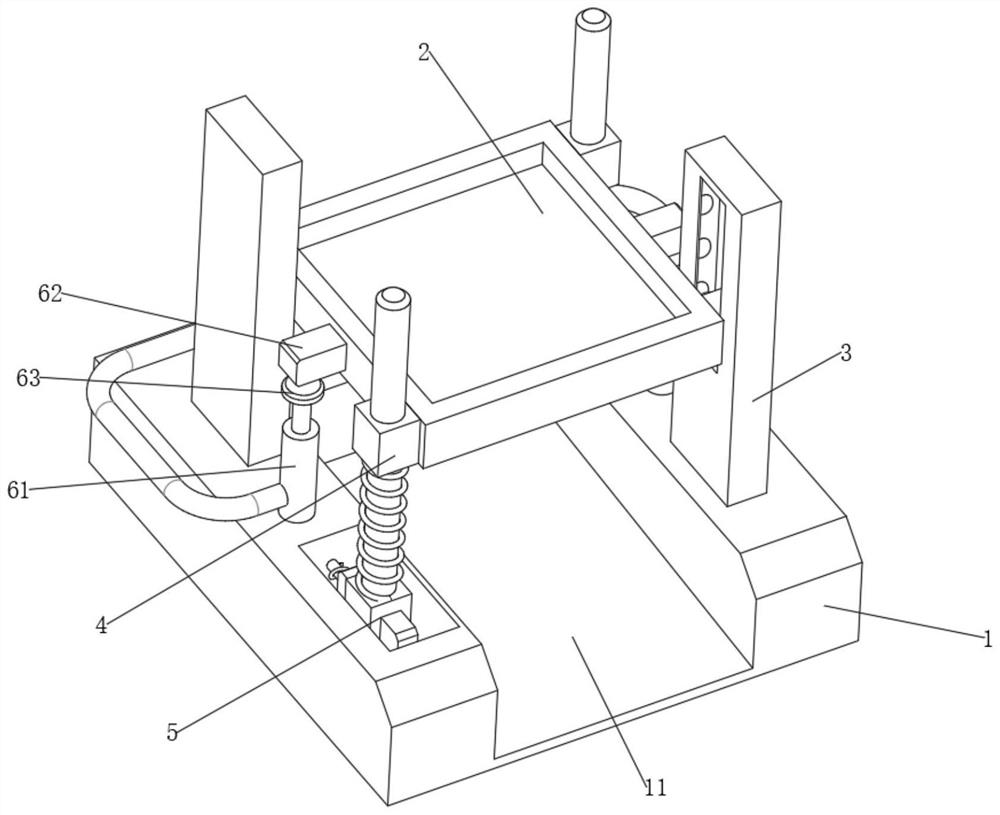

[0042] see Figure 1-5 The present embodiment discloses a sand screening device for house construction, comprising a base 1, a sieve plate 2 is slidably arranged on the base 1, a discharge port 11 is also opened on the base 1, an oscillating mechanism 3 is arranged on the base 1, and the screen is The plate 2 is slidably arranged in the oscillating mechanism 3;

[0043] The oscillating mechanism 3 includes an outer frame 31 arranged on the base 1, and an oscillating block 32 is arranged on the sieve plate 2, and the oscillating block 32 is slidably arranged in the outer frame 31;

[0044] The outer frame 31 is also provided with a first resistance block 33 and a second resistance block 34 respectively, and a reaction block 35 is arranged on the vibration block 32 .

[0045]In this embodiment: in order to enable the sieve plate 2 to oscillate and screen the sand and soil placed in it, an oscillating mechanism 3 is provided on the base 1, and the sieve plate 2 is slidably arran...

Embodiment 2

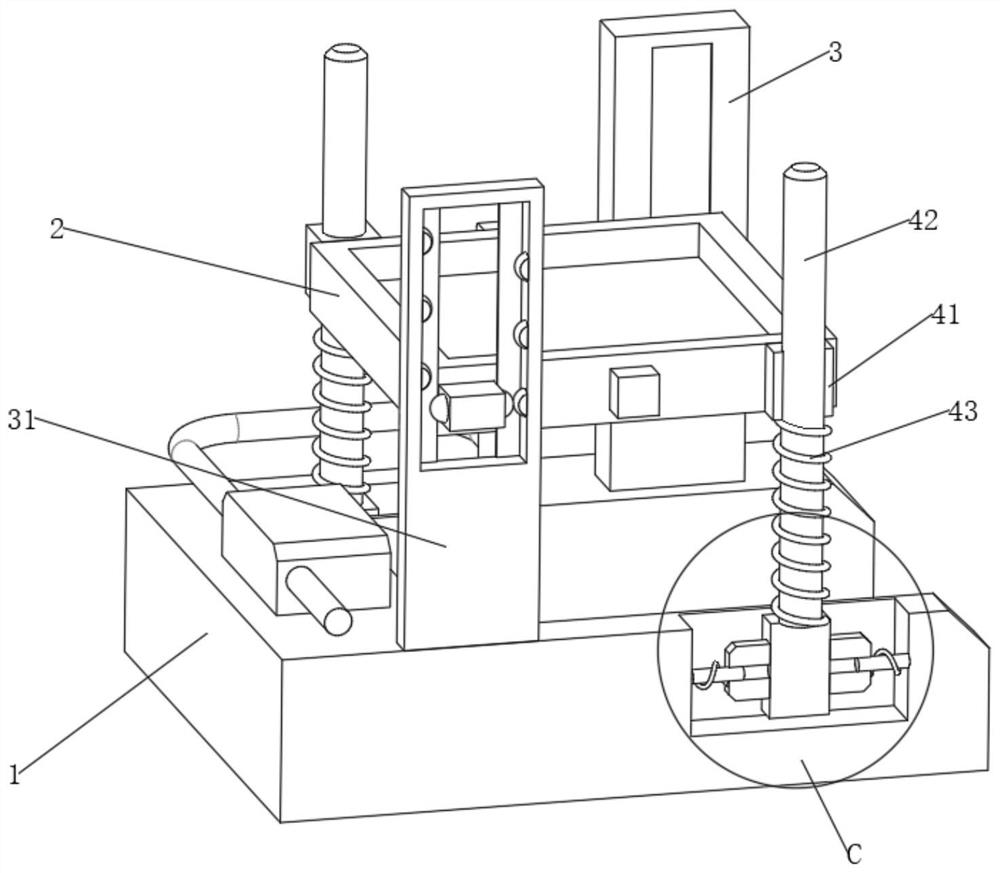

[0049] This embodiment is an improvement made on the basis of Embodiment 1, please refer to Figure 1-5 , the first resistance block 33 and the second resistance block 34 are alternately arranged in the outer frame 31 , and the hardness of the reaction block 35 is greater than the hardness of the first resistance block 33 and the second resistance block 34 .

[0050] In this embodiment: in order to make the oscillating block 32 shake in the outer frame 31, so that the sieve plate 2 can be oscillated, it can also ensure that the sieve plate 2 can fall back normally, the first interference block 33 and the second interference The blocks 34 are arranged in the outer frame 31 in a staggered manner, thus ensuring that when the first conflicting block 33 and the second conflicting block 34 abut against the reaction block 35, the reaction block 35 will oscillate reciprocally, thereby making the sieve plate 2 complete the oscillation.

[0051] In order to ensure that the vibration blo...

Embodiment 3

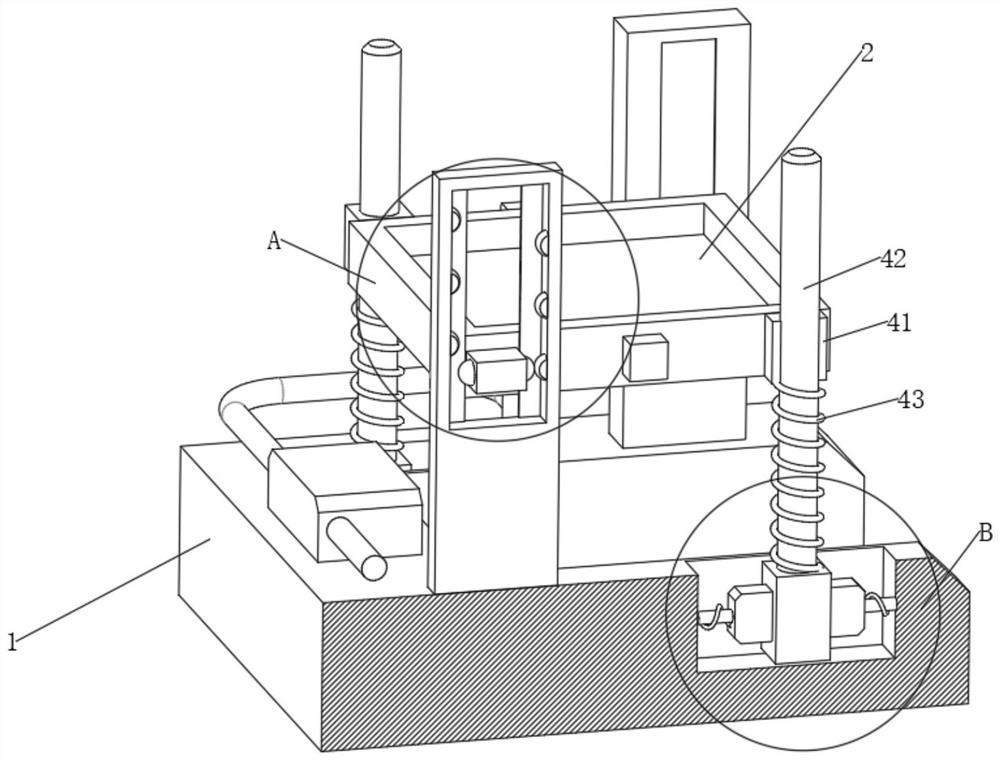

[0053] This embodiment is an improvement made on the basis of Embodiment 2, please refer to Figure 1-6 , the base 1 is also provided with a stabilization mechanism 4, and the base 1 is also connected with the sieve plate 2 through the stabilization mechanism 4;

[0054] The stabilization mechanism 4 includes a sliding rod 42 mounted on the base 1 , a sliding block 41 is provided on the screen plate 2 , and the sliding block 41 is slidably arranged on the sliding rod 42 .

[0055] In this embodiment: in order to support the sieve plate 2 so that it can maintain a relatively stable sliding during vibration, a stabilization mechanism 4 is also provided on the base 1, and a stabilization mechanism is also provided between the base 1 and the sieve plate 2. 4 Make connections.

[0056] The stabilization mechanism 4 includes a sliding rod 42 mounted on the base 1 , a sliding block 41 is provided on the screen plate 2 , and the sliding block 41 is slidably arranged on the sliding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com