Positive and negative pressure air suction type roller precision seed-metering device

A technology of seed metering device and roller, which is applied in the direction of agricultural gas emission reduction, seeding, seeder parts, etc., and can solve problems such as seeding instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

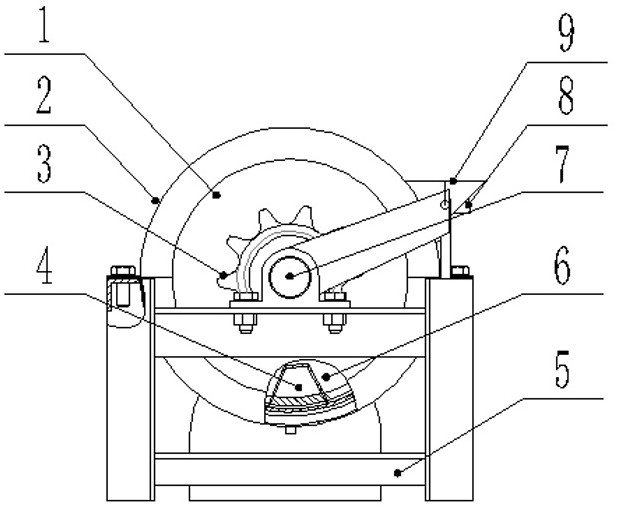

[0015] like figure 1 As shown, the drum 1 is inside the casing 2, and there is a certain gap between the two. The hollow shaft 7 is fixed on the frame 5 through nuts. The shells on both sides and the drum 1 form a negative pressure zone 6, and the positive pressure zone 4 passes through The seeding hole is connected with the outside world, and the vibration module 8 is installed on the seed box 9 .

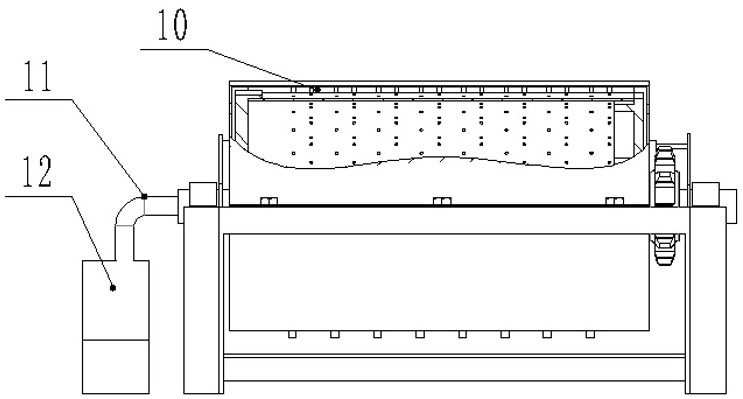

[0016] like figure 2 As shown, the fan 12 is connected to the hollow shaft 7 fixed on the frame through the air pipe 11 to provide negative pressure, and the brush 10 is installed on the housing to reduce the reseeding rate by brushing away unnecessary seeds without injury. Just below the shell 2, so that when the seeds enter the positive pressure zone, they can be discharged by gravity.

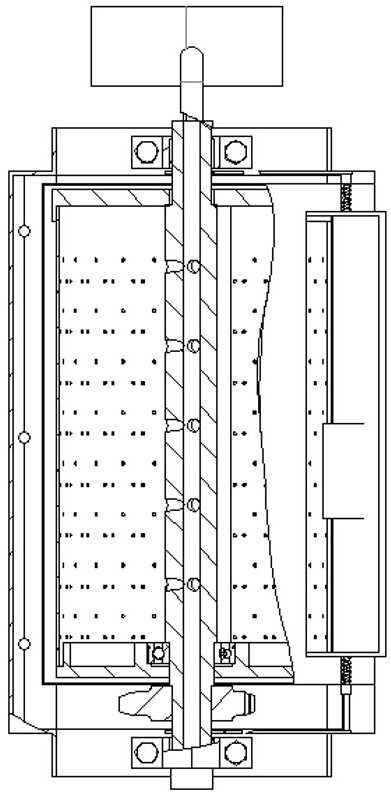

[0017] like image 3 As shown, the vibrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com