Five-phase permanent magnet motor short-circuit fault-tolerant control method considering rotor magnetic field harmonic waves

A permanent magnet motor and rotor magnetic field technology, applied in motor control, AC motor control, motor, etc., can solve problems affecting the operating characteristics of multi-phase permanent magnet motors, and achieve the effect of improving torque output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

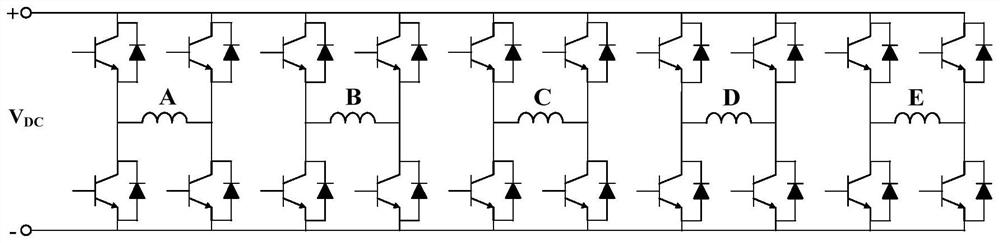

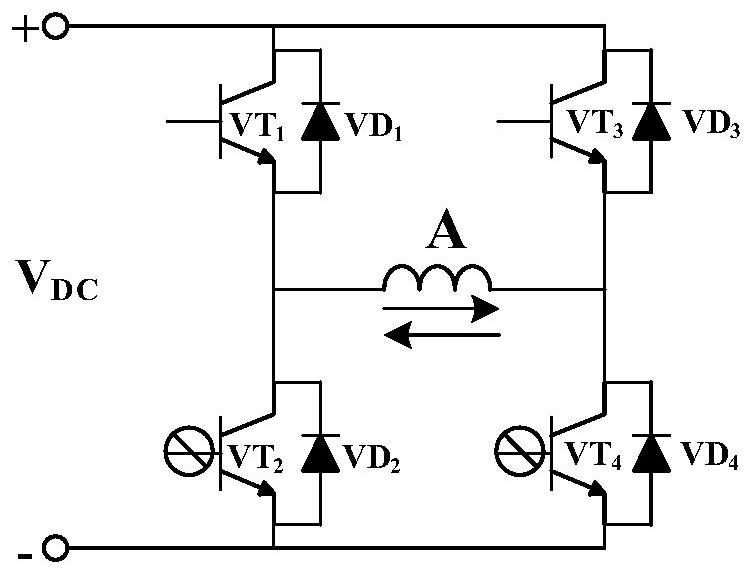

[0046] Specific embodiment one: the following combination Figure 1 to Figure 2 This embodiment will be described. The fault-tolerant control method for short-circuit faults of five-phase permanent magnet motors considering rotor magnetic field harmonics in this embodiment is the same as the fault-tolerant control method for short-circuit faults at the ends of any one-phase windings A, B, C, D, and E. Taking the partial short circuit as an example, the fault-tolerant control method of the five-phase permanent magnet motor when any one-phase winding end is short-circuited is as follows:

[0047] In order to consider the influence of the higher harmonics of the rotor magnetic field on the torque output characteristics under short-circuit fault, and to take into account the amount of data in the current solution process, the third harmonic of the rotor magnetic field, which has a greater impact on the short-circuit current, is mainly considered when analyzing the short-circuit cu...

Embodiment

[0069] Example: A specific example in the case of a short-circuit fault at the end of a one-phase winding is given below.

[0070] Taking a five-phase permanent magnet motor with 15 slots and 12 poles as an example, the output torque characteristics of the five-phase permanent magnet motor in the normal state, the short-circuit state at the end of the one-phase winding, and the method of the present invention are respectively given, such as Table 1 shows the advantages of the method of the present invention.

[0071] Table 1 Comparison of torque characteristics under normal state and A-phase terminal short-circuit fault state

[0072]

[0073] It can be seen that the use of the five-phase permanent magnet motor short-circuit fault tolerance control method considering the rotor magnetic field harmonics of the present invention can significantly reduce the torque fluctuation of the five-phase permanent magnet motor under the short-circuit fault of the one-phase winding end, a...

specific Embodiment approach 2

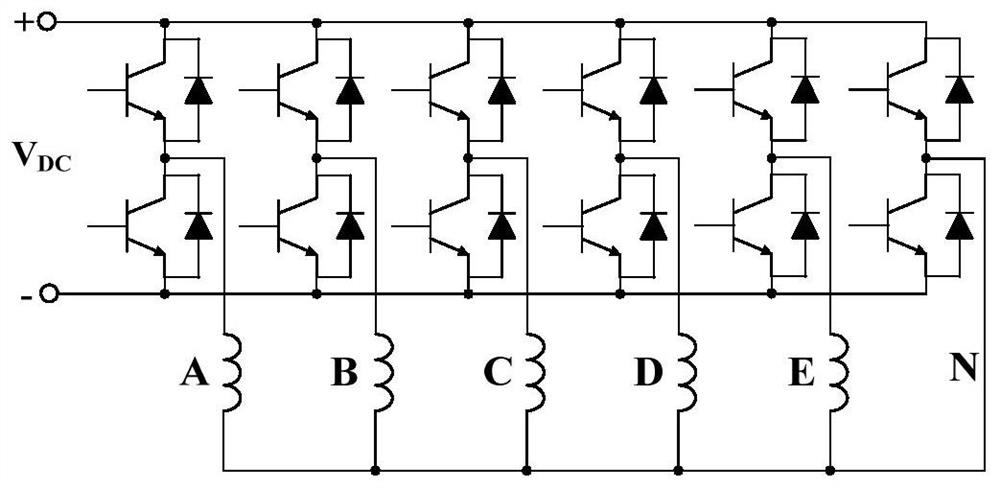

[0074] Specific embodiment two: the following combination image 3 and Figure 4 This embodiment is described. This embodiment further describes Embodiment 1. The short-circuit fault covers the short-circuit of the end of the winding and the short-circuit of some turns, and one of the situations where the bridge arm of the inverter where the winding is located has a short-circuit of the switch tube. its combination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com