Welding seam ultrasonic image defect identification method based on machine and depth vision fusion

A deep vision and defect identification technology, applied in the field of defect identification, can solve the problems that the identification quality and identification speed cannot meet the needs of enterprises, the difficulty of quality retrospection and process improvement, and the cumbersome manual identification steps, so as to achieve fast and accurate defect identification and reduce labor. Rely on experience and solve the cumbersome and time-consuming effect of labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

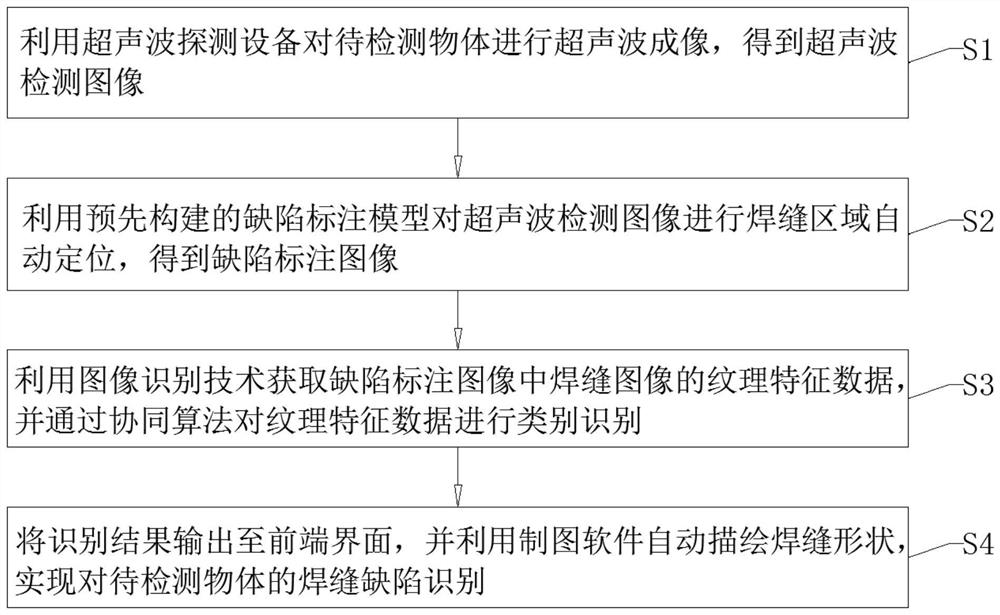

[0060] In order to further illustrate the various embodiments, the present invention provides accompanying drawings, which are part of the disclosure of the present invention, and are mainly used to illustrate the embodiments, and can be used in conjunction with the relevant descriptions in the specification to explain the operating principles of the embodiments, for reference Those of ordinary skill in the art should be able to understand other possible implementations and advantages of the present invention. The components in the figures are not drawn to scale, and similar component symbols are generally used to represent similar components.

[0061] According to the embodiments of the present invention, a method for identifying defects in ultrasonic images of welding seams and a method for overhauling elevator guide components based on fusion of machine and depth vision are provided.

[0062] Now in conjunction with accompanying drawing and specific embodiment the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com