Metal plate production line integrated system

An integrated system and production line technology, applied in the field of sheet metal processing, can solve problems such as relying on the working time and level of engineers, manual quotations are highly controlled by personnel, and communication errors, etc., to optimize sheet metal design methods and improve management. , the effect of improving the management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

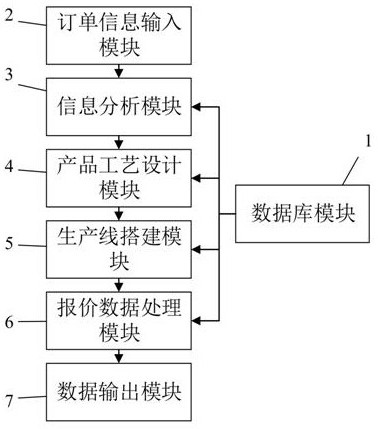

[0019] The invention provides an integrated system of a sheet metal production line, such as figure 1 As shown, it includes: database module 1, order information input module 2, information analysis module 3, product process design module 4, production line construction module 5, quotation data processing module 6, and data output module 7.

[0020] The database module 1 is used to store decomposed and serialized design data, process data, material parameters, material cost unit price, human resource information, module equipment information, production molds and accessories, and material supplier data of each functional sub-module of the sheet metal production line , equipment supplier data and other data information....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com