Fixture for flaring test of alloy protective sleeve of railway through ground wire

A railway through ground wire and flaring test technology, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of difficulty in grasping the clamping force of the sheath tube, and achieve the effect of stable and good test and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

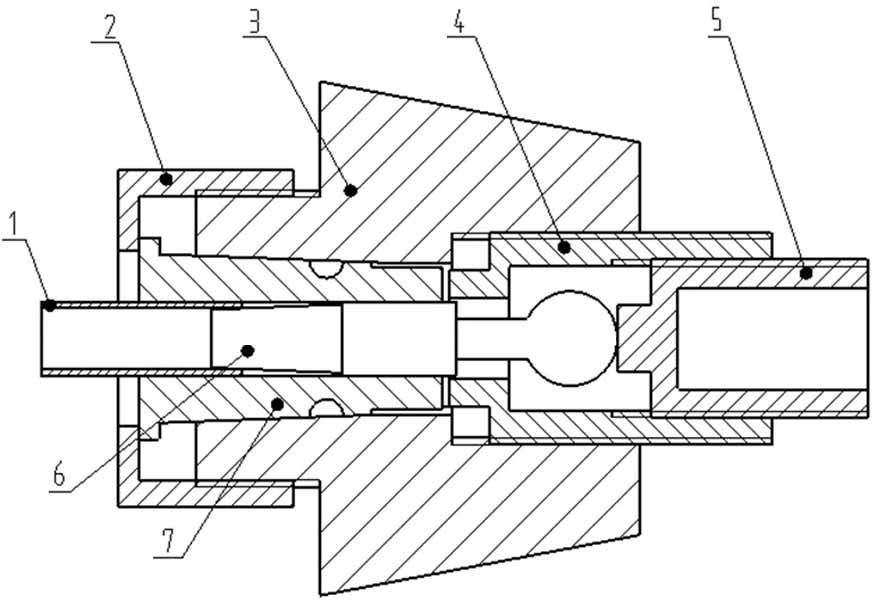

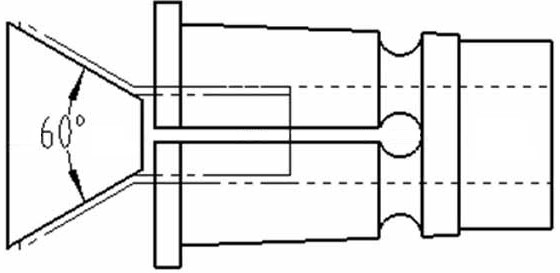

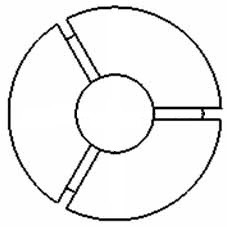

[0014] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , the chuck 7 has a tapered surface on the outside, the chuck 7 is fixed in the fixed seat 3 through the taper surface, the pressure cap 2 and the fixed seat 3 are connected by threaded connection, the inner bottom wall of the pressure cap 2 presses the chuck 7, the chuck 7 produces deformation clamping alloy sheath 1 . The tightening length of the pressure cap 2 and the collet 7 can be controlled, so that the length of the collet 7 entering the fixed seat 3 is also controlled, so the clamping force of the collet 7 can be adjusted, and the alloy sheath is in contact with the inner hole wall of the collet The area is large, so a large clamping force can be obtained, and the alloy sheath is not easily deformed. The inner tip 6 is set in the chuck 7, and the inner wall of the alloy sheath 1 is pressed against the small taper surface of the inner tip 6. The guide shaft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com