PU (polyurethane) double-layer crystal mirror leather and laminating method thereof

A technology of mirror leather and crystal, which is applied in the direction of layered products, textiles and papermaking, etc., can solve the problems of high cost, poor transparency, and low efficiency, and achieve low cost, improved transparency and efficiency, and transparent good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

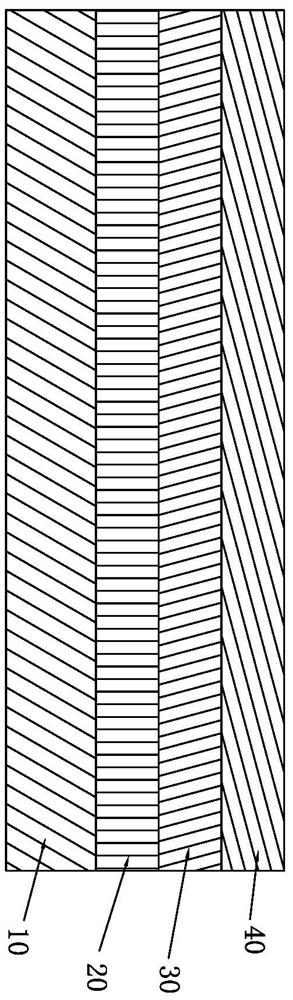

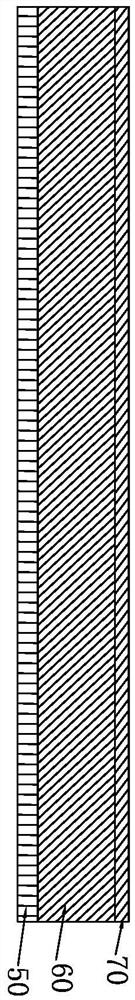

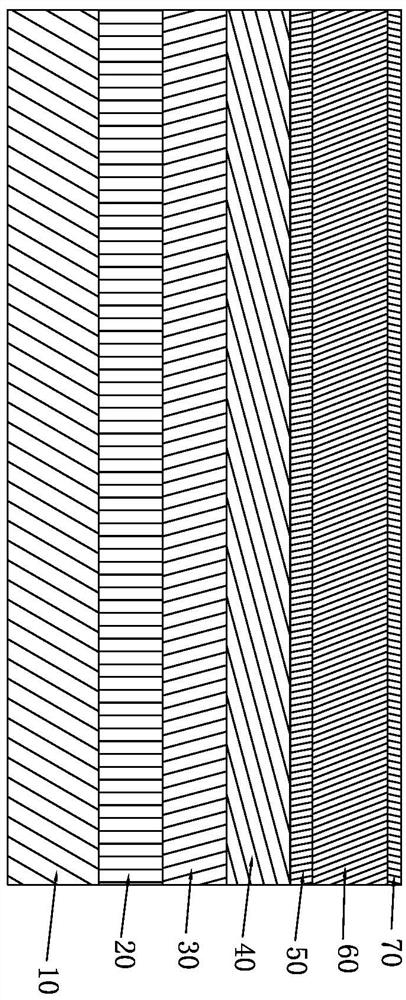

[0030] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the embodiment of the present invention.

[0031] A PU double-layer crystal mirror leather, comprising a base fabric 10, a wet-process PU layer 20, a dry-process PU texture layer 30, a printing layer 40, an adhesive layer 50, and a transparent polyurethane elastomer 60. Use transparent polyurethane elastomer resin to increase the crystal transparency and softness of the product, and inject additives on the surface of the dry layer texture and then paste transparent polyurethane elastomer 60 to expel air bubbles from the PU Leather surface, reduce original air bubbles and improve permeability and efficiency.

[0032] The laminating method of described PU double-layer crystal mirror leather comprises the following steps:

[0033] Step 1: Coating a wet-process PU layer 20 above the base cloth 10;

[0034] Step 2: coating the dry-process PU texture layer 30 on the wet-process PU layer 20; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com