Hair washing device for solid-phase microporous reactor and use method

The technology of a shampooing device and a reactor is applied in the directions of chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., and can solve the problems of insufficient washing, excessive time, weak suction force of attachments on the reaction interface of the peripheral wall, etc. , to achieve good washing effect, improve efficiency and effect, and shorten the cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

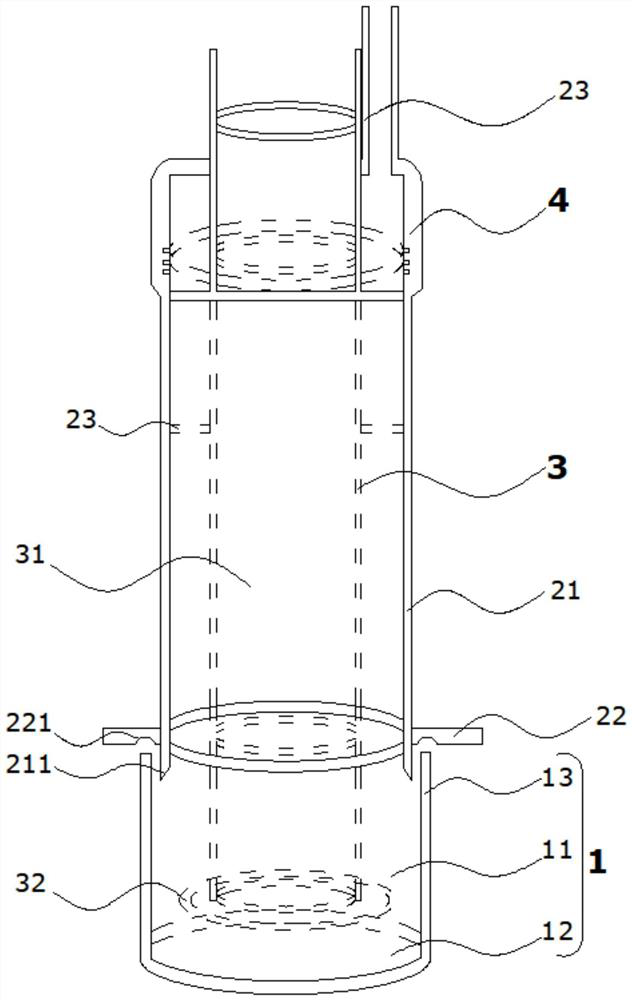

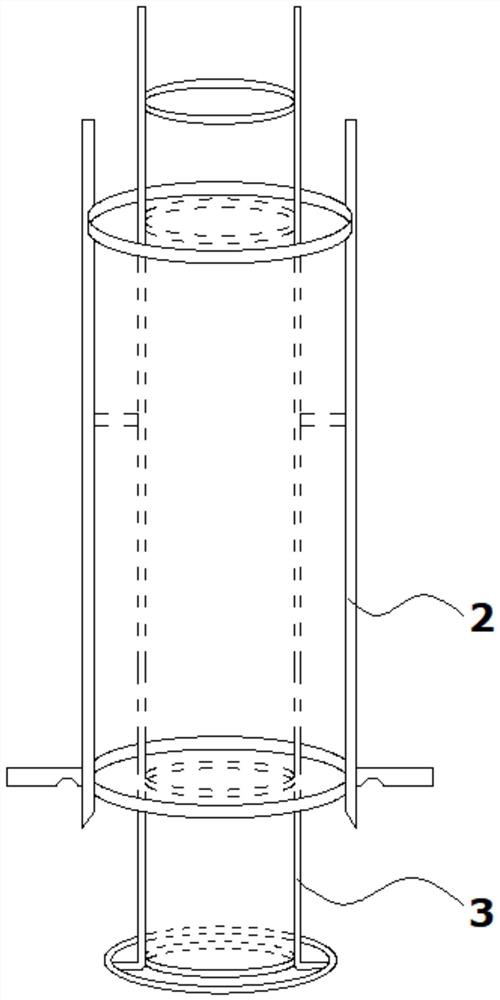

[0038] refer to Figure 1-6 As shown, a solid-phase microporous reactor hair washing device includes: a solid-phase micropore 1 with a top open and hollow, and the solid-phase micropore 1 includes a micropore cavity 11, and the micropore cavity The top of 11 is provided with a hole edge 13, and the bottom surface of the micropore cavity 11 may be provided with a gain structure 12;

[0039] The shampoo injection structure 2 includes a lotion cavity 21 that goes deep into the micropore cavity and is spaced apart from the inner wall of the micropore cavity 11. The outer peripheral surface of the lotion cavity 21 extends outwardly and has a bridge erected on the hole edge 13. The platform at the top is along 22, and the two axial ends of the lotion chamber 21 are respectively provided with an upper opening and a lower opening. Injection tube 23;

[0040]The waste liquid suction and discharge structure 3 vertically passing through the upper opening and the lower opening of the wa...

Embodiment 2

[0056] This embodiment is basically the same as Embodiment 1, the difference is that:

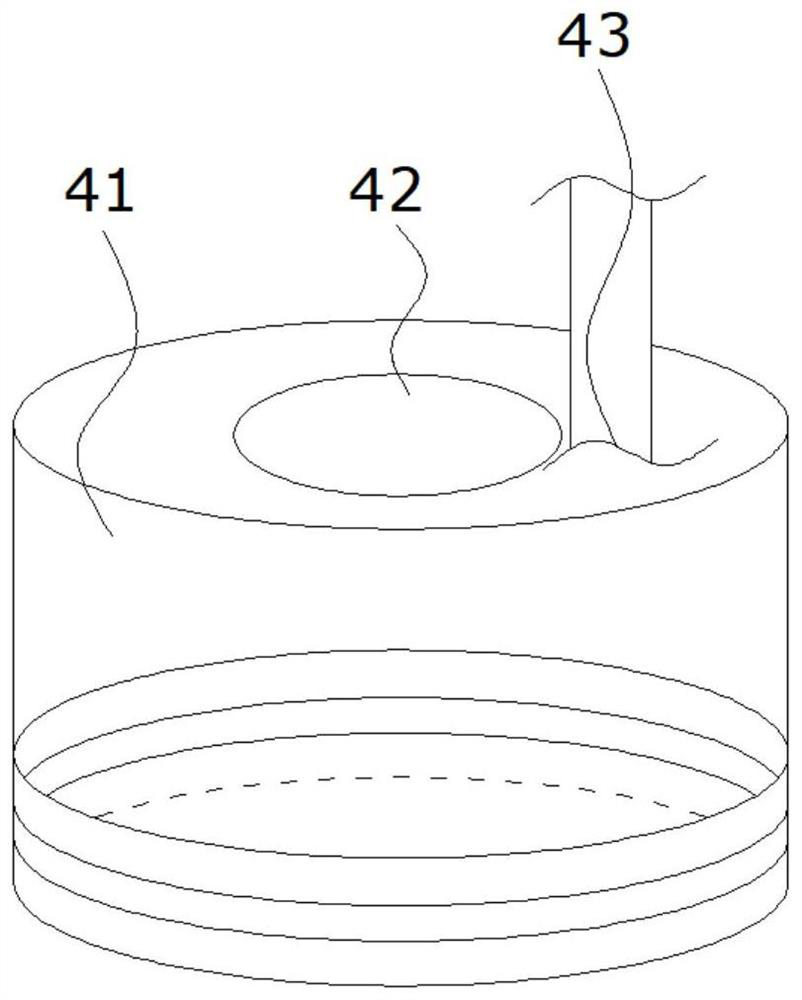

[0057] refer to Figure 5 , the gain structure 12 is a rotating body. In order to increase the contact surface area, the gain structure 12 is set as a rotating body. Correspondingly, the extension 32 in this embodiment is a hollow circular frustum structure with two ends open, and the circular frustum structure cover It is arranged above the entire rotating body so that the extension edge 32 can adapt to the shape of the rotating body and improve its suction efficiency.

[0058] It should be emphasized that due to the needs of immunoassays, the gain structure 12 needs to be set as a rotating body to increase the surface area. On the contrary, due to the use of a rotating body structure, due to its special-shaped structure during suction, There must be problems such as difficult suction and incomplete suction, but after adopting the corresponding extension edge 32, the negative pressure gen...

Embodiment 3

[0060] This embodiment is basically the same as Embodiments 1 and 2, except that:

[0061] refer to Figure 6 , the gain structure 12 is a rotating body with a groove 221, also in order to increase the contact surface area, the gain structure 12 is set as a rotating body with a groove 221, the same as the second embodiment, in this embodiment The extension edge 32 is also a hollow circular platform structure with two ends open, but since the rotating body is provided with grooves 221, the overall height is reduced, correspondingly, the height of the extension edge 32 is also reduced, and the negative pressure of the exhaust is concentrated The point is also reduced, enabling the extension 32 to adapt to the shape of the rotating body, increasing its suction efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com