Textile size stirring equipment for spinning

A technology for textile sizing and stirring equipment, which is used in mixer accessories, mixers, dissolving and other directions, can solve the problems of inability to mix textile sizing, unsatisfactory stirring effect, uneven stirring, etc., to reduce layering phenomenon and stirring effect. Good, improve the effect of stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

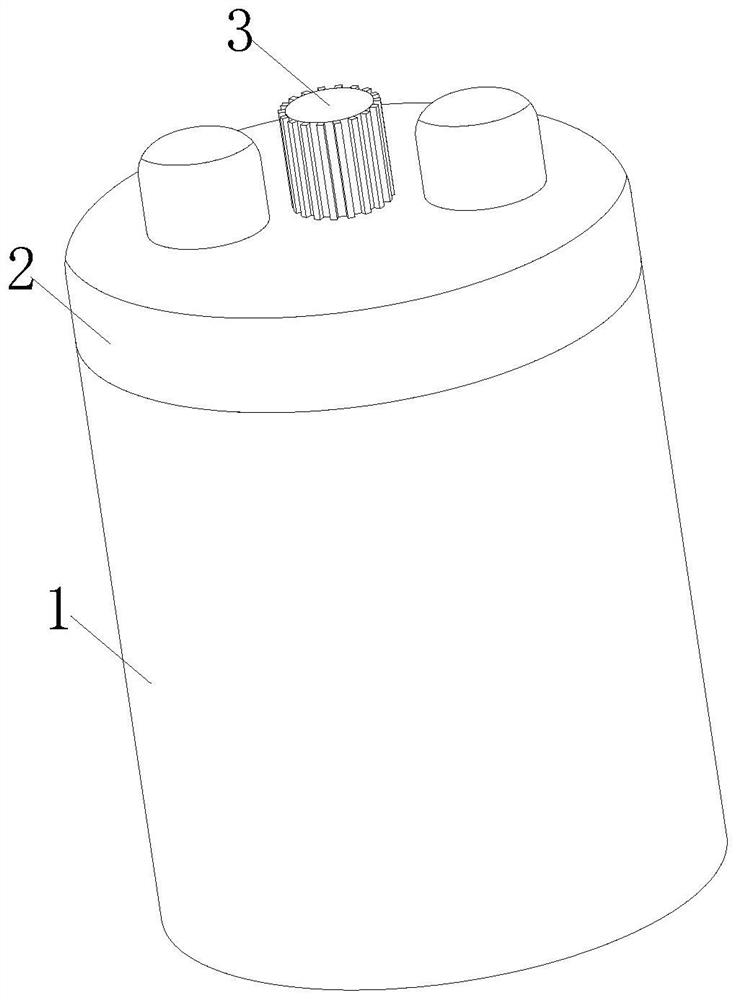

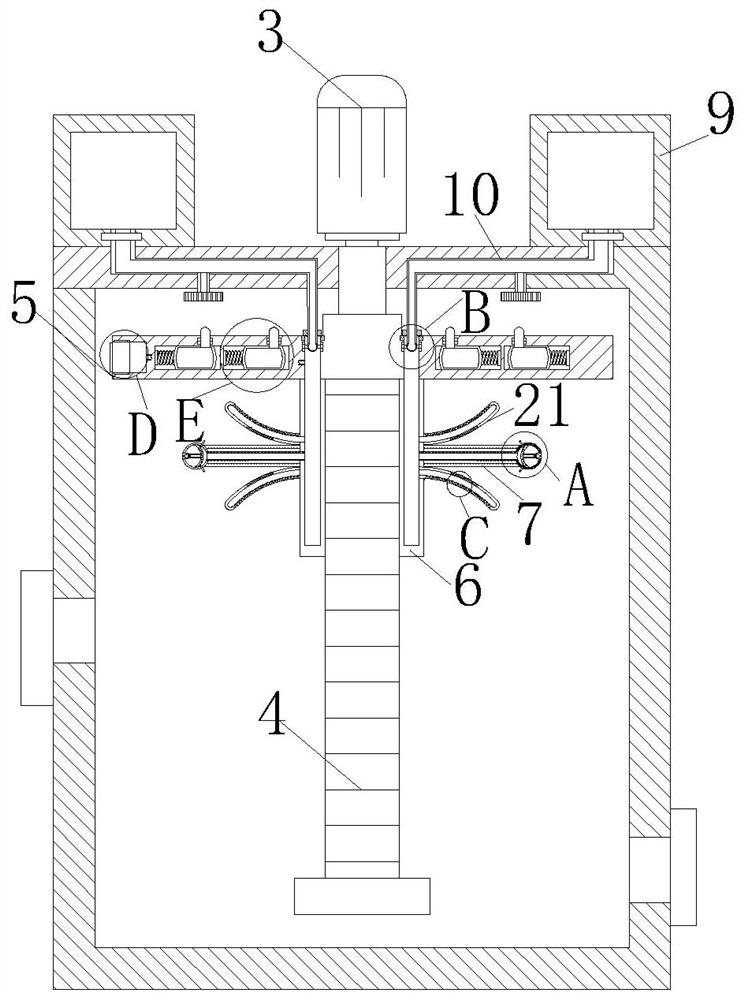

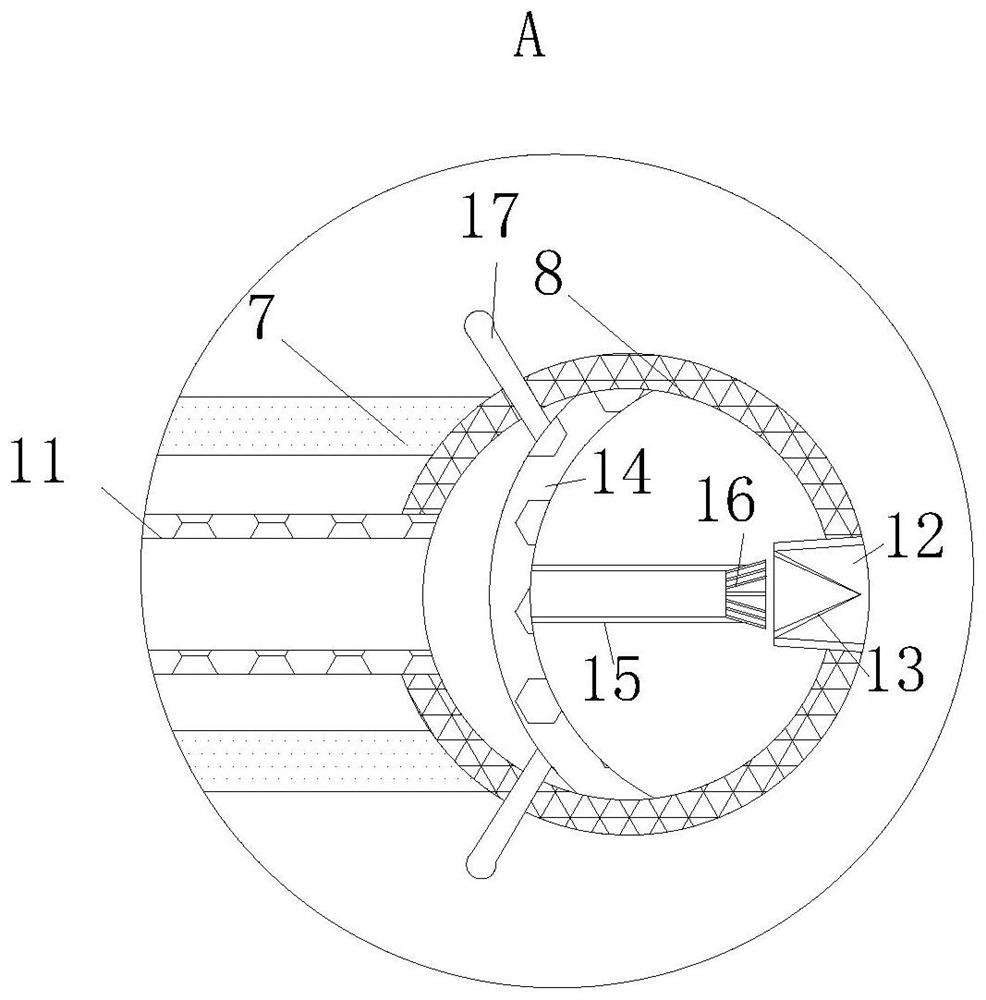

[0030] as Figures 1 through 6As shown, an embodiment of the present invention is a textile slurry stirring apparatus for textiles, comprising a housing 1, the top surface of the housing 1 is close to the edge position threaded connected to the cover 2, the top surface of the cover 2 is fixed near the middle position is fixed with a motor 3, the output shaft of the motor 3 is fixed connected to the rotary rod 4, one end of the rotary rod 4 extends to the interior of the housing 1, the outer surface of the rotary rod 4 is threaded with a stirring plate 5. When working, by setting the housing 1, the staff first through the inlet to the inside of the shell 1 to add textile slurry, when the addition is not completed, the control system controls the motor 3 forward rotation, because the mixing plate 5 and the rotary rod 4 thread connection, at this time, the stirring plate 5 rotates down inside the shell 1, the textile slurry inside the shell 1 is stirred downwards, reducing the delamin...

Embodiment 2

[0040] as Figure 7As shown, compared with example one, wherein another embodiment of the present invention is: the stirring plate 5 is provided with a uniformly distributed mounting groove 28, the inner surface of the mounting groove 28 is fixed in one side near the intermediate position is fixed with a spring 29, one end of the spring 29 is fixed with a second airbag 30, the top surface of the second airbag 30 is close to the edge of the side of the position through which the ejector rod 31 is connected, the ejector rod 31 is connected to the stirring plate 5 through the activity connection. When working, the present invention by setting the mounting tank 28, in the process of rotation of the stirring plate 5, the centrifugal force when the water inside the second airbag 30 moves away from the direction of the rotary rod 4, i.e., to overcome the elastic force of the spring 29 in the direction of the installation slot 28 to move away from the direction of the rotary rod 4, i.e., t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com