Wire dividing machine for cable processing

A wire-splitting and cable technology, applied in the field of wire-splitting machines for cable processing, can solve the problems of easy winding of wire cores and low efficiency of manual wire-splitting, and achieve the effects of improving production efficiency, ensuring independence and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

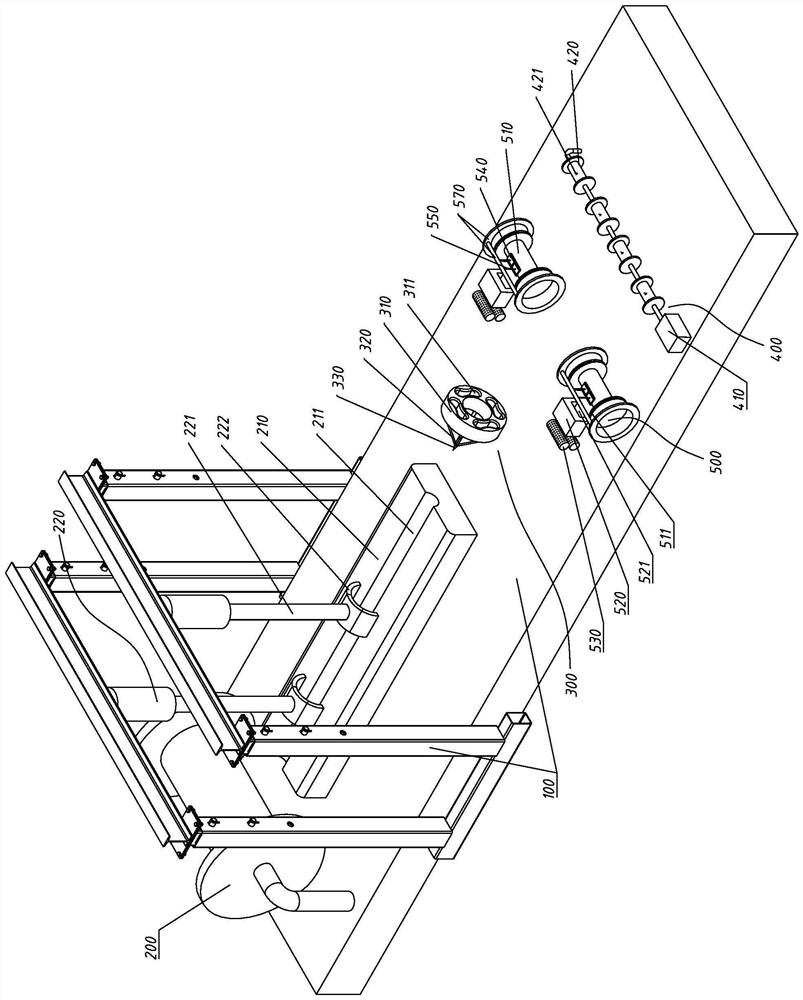

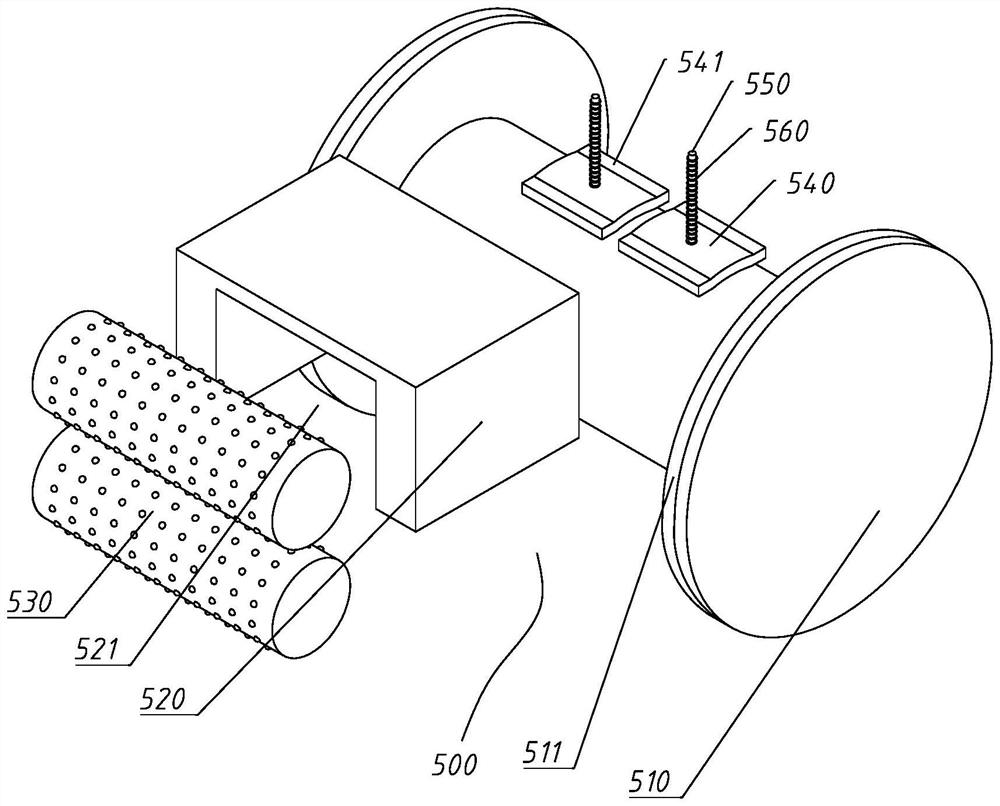

[0044] Such as Figure 1 to Figure 4 As shown, this embodiment proposes a wire splitting machine for cable processing, including

[0045] Rack 100;

[0046] The pay-off roller 200 is rotatably arranged on the frame 100;

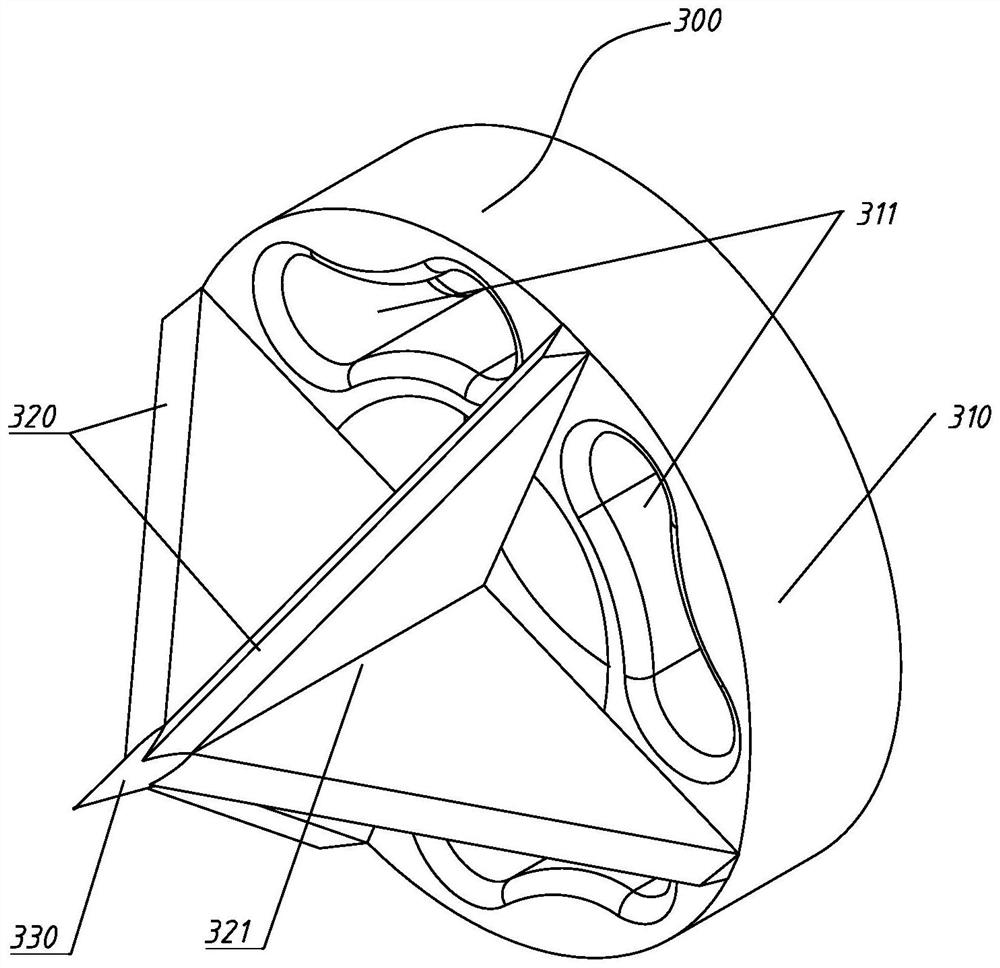

[0047] The stripping unit 300 is arranged on one side of the pay-off roller 200, and the stripping unit 300 has

[0048] block 310;

[0049] The stripping blade 320 is arranged on the stopper 310, and several stripping blades 320 are arranged along the circumference of the stopper 310, and the intersecting parts of several stripping blades 320 form a reinforcing part 321; and

[0050] The line splitting cone 330 is arranged on the reinforcing part 321 , and the tip of the line splitting cone 330 faces the pay-off roller 200 .

[0051] In this embodiment, in order to solve the problem that the efficiency of manual wire splitting is low and the wire core is easy to be entangled after peeling, a wire splitting machine for cable processing is now designed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com