Detection method for dielectric property of ceramic powder and application of detection method

A technology for ceramic powder and dielectric properties, which is applied in the field of functional material testing, can solve the problems of difficulty in meeting the requirements of high-frequency dielectric materials, low Df test accuracy, low relative dielectric constant, etc., and achieves a simple sample preparation process. Effective, small error, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

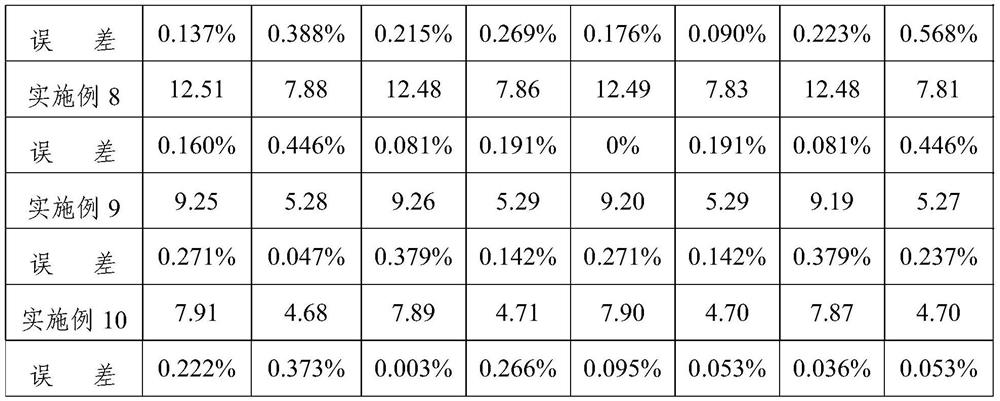

Examples

Embodiment 1

[0029] This embodiment provides a method for detecting the dielectric properties of ceramic powder, the specific steps are as follows:

[0030] S1. Titanium dioxide powder (particle size is 20 μm, spherical shape, impurity content <1wt%) and dispersed PTFE resin (particle size is 10 μm) are added to the high-speed mixer at a mass ratio of 10:5, and the mixture is evenly mixed at a stirring rate of 8000 rpm. Disperse and mix for 120s, set aside;

[0031] S2. Transfer the homogeneously mixed materials into a mixing container, add titanium dioxide and petroleum ether with a total mass of 25% of PTFE resin, stir quickly until it is in the shape of "bread crumbs", and seal it for later use;

[0032] S3, aging the material of S2 at room temperature for 20 minutes;

[0033] S4, the material of S3 is rolled into a sheet-like sample of PTFE / titanium dioxide / petroleum ether through a film rolling machine with a rotating speed of 9 rpm and a roll spacing of 0.6 μm;

[0034] S5, put the...

Embodiment 2

[0039] The difference between the testing method for the dielectric properties of the ceramic powder provided in this example and Example 1 is that the mixing time in step S1 is 0 s, that is, the PTFE resin does not undergo dispersion treatment.

[0040] After testing, at room temperature, the sample density is 3.015g / cm 3 , The dielectric constant is 10.45 at 10GHz, and the dielectric loss is 0.000715.

Embodiment 3

[0042] The difference between the detection method provided in this example and Example 1 is that the forming agent in step S2 is aviation kerosene.

[0043] After testing, at room temperature, the sample density is 2.868g / cm 3 , The dielectric constant is 8.99 at 10GHz, and the dielectric loss is 0.000675.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com