System and method for measuring calorific value of equipment in subway equipment room

A measurement system and measurement method technology, applied in the direction of measuring heat, measuring devices, calorimeters, etc., can solve the problems of difficulty in determining the equipment load of the equipment room, large calculation value of calorific value, and large proportion, etc., to save installed capacity and Construction cost, reduction of energy consumption and carbon emissions, effect of reducing design value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

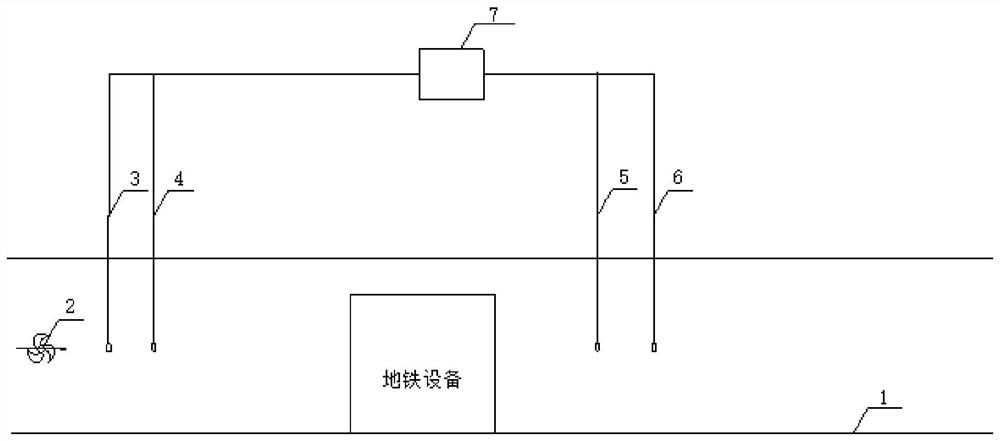

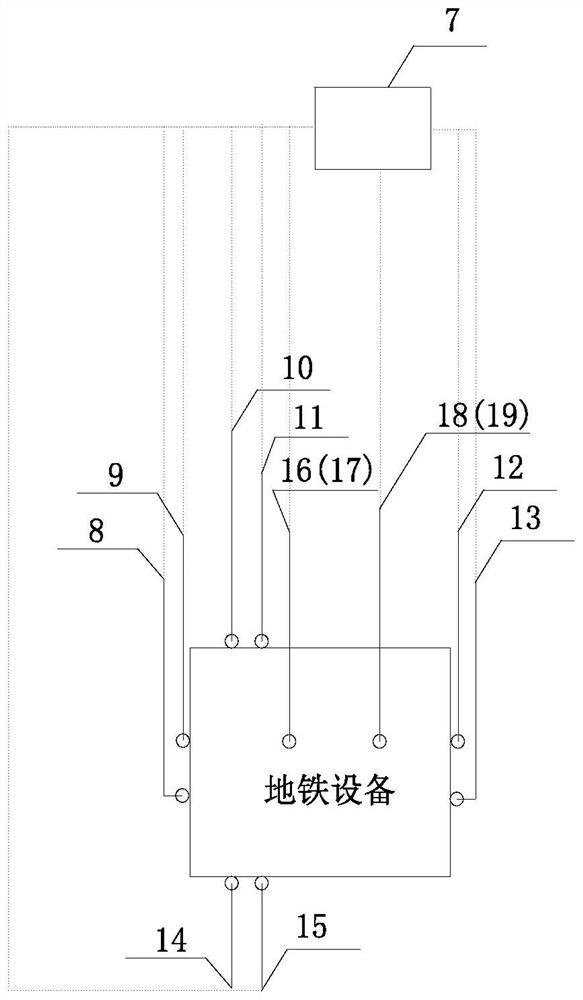

[0034] Such as figure 1 and figure 2 As shown, the present embodiment provides a system for measuring the calorific value of equipment in a subway equipment room, including an indirect method for measuring the calorific value of subway equipment and a direct method for measuring the calorific value of subway equipment connected to the same data logger 7. for recording and saving sensor data.

[0035]The system for measuring the calorific value of subway equipment by the indirect method includes an insulated canvas wind bag 1, two enthalpy sensors, two air volume sensors, and a fan 2, wherein the sensors are connected to a data recorder 7.

[0036] Such as figure 1 As shown, the adiabatic canvas airbag 1 covers the subway equipment, and an air outlet is provided at both ends of the adiabatic canvas airbag 1, one air inlet is used for air intake, and the other air outlet is used for air exhaust; the fan 2 is used for The air flows in the air bag to provide power, the air inl...

Embodiment 2

[0040] Utilizing a kind of system for measuring the calorific value of equipment in a subway equipment room in Embodiment 1, this embodiment provides a method for measuring the calorific value of equipment in a subway equipment room. The following steps are used to determine the calorific value of subway equipment:

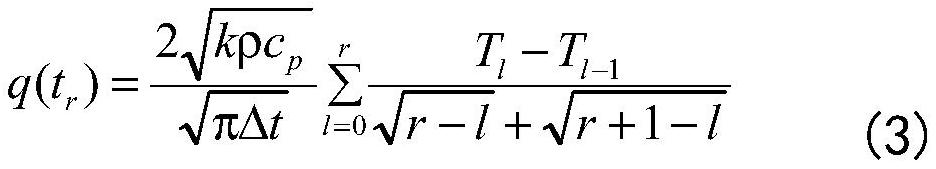

[0041] Step 1, according to the data obtained by measuring the heating value of subway equipment by the indirect method, calculate the heating value Q of subway equipment 1 calculation.

[0042] Specifically, formula (1) is used to calculate the calorific value Q of subway equipment 1 The calculation of , where formula (1) is as follows:

[0043] Q 1 =m in h in -m out h out (1)

[0044] In the formula, m in is the mass flow rate at the air inlet of the wind bag; m out is the mass flow rate at the air outlet of the wind bag; h in is the enthalpy value of the air at the air inlet of the wind bag; h out is the air enthalpy at the air outlet of the wind ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com