Combined high-efficiency air preheater and preheating method thereof

An air preheater and high-efficiency technology, applied in the field of combined high-efficiency air preheater, combined high-efficiency air preheater, and air preheater preheating, can solve the problem of inability to achieve automatic cycle preheating. Problems such as heat, energy waste, filter structure without good energy-saving cleaning structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

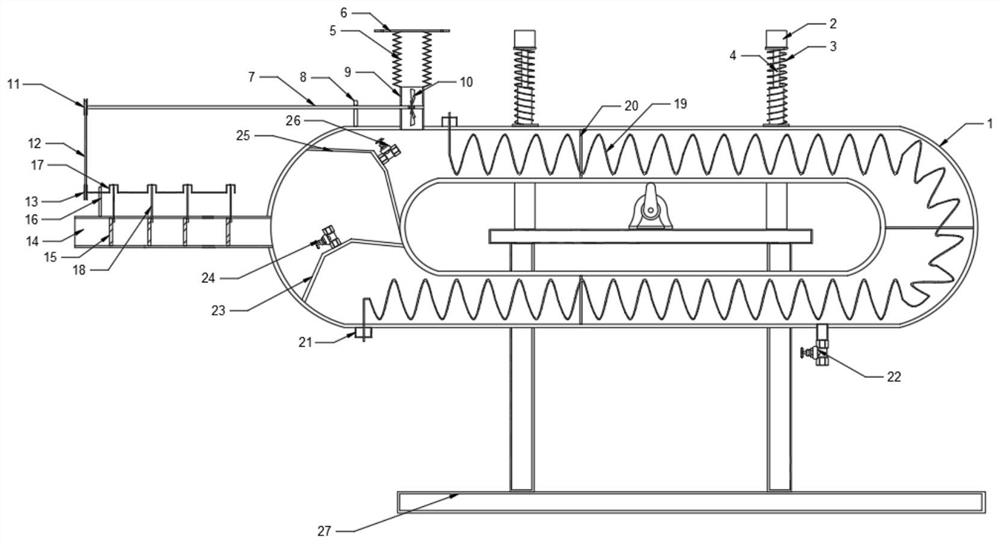

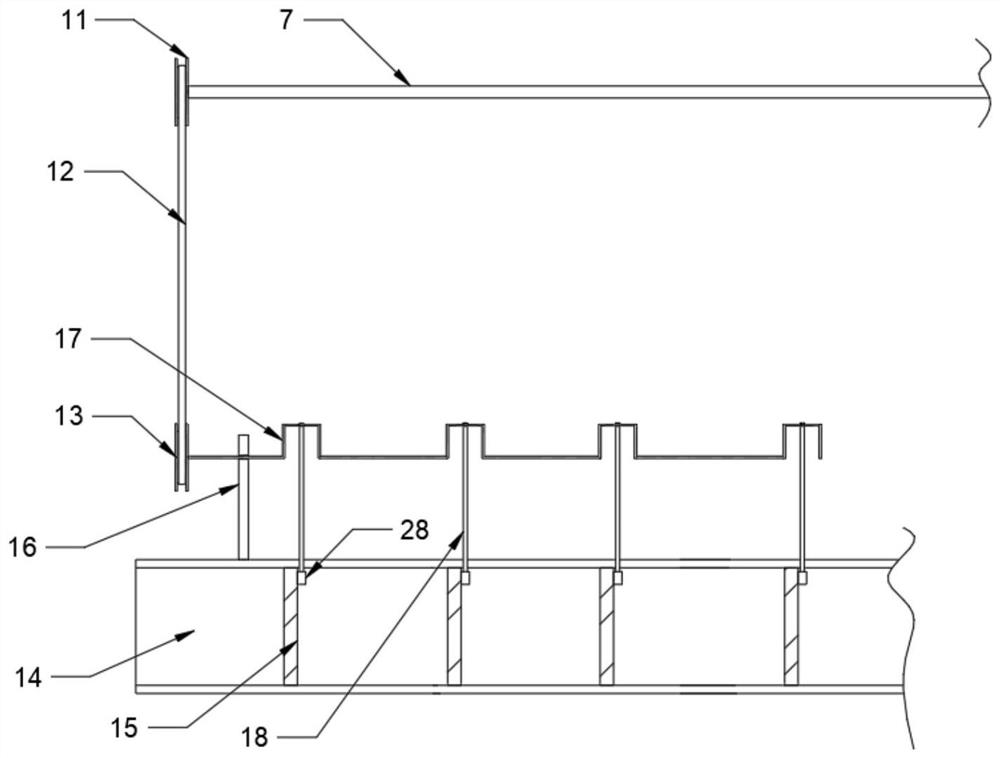

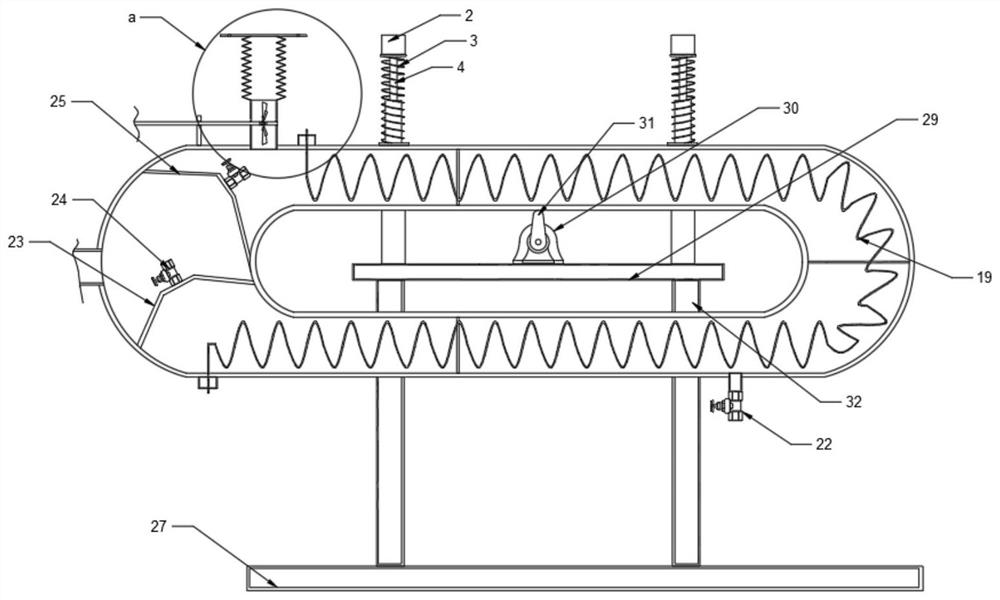

[0039] Such as Figure 1-Figure 6 As shown, a combined high-efficiency air preheater provided in this embodiment includes a hollow elliptical heat exchange chamber 1, and support frames 20 are installed at equal intervals inside the hollow elliptical heat exchange chamber 1, and the support frame 20 An air-introduction spiral frame assembly is installed on the top, and the input and output ends of the air-introduction spiral frame assembly both pass through the hollow oval heat exchange chamber 1, and a high-temperature steam introduction connecting pipe assembly is installed on the top side of the hollow oval heat exchange chamber 1. The inner side of the high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com