Steel structure fabricated building

A prefabricated, steel structure technology, applied in buildings, protected buildings/shelters, building components, etc., can solve the waste of wall panels, the lifting of the weight of wall trusses, and the connection between wall trusses and vertical support rods. concave inequality problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

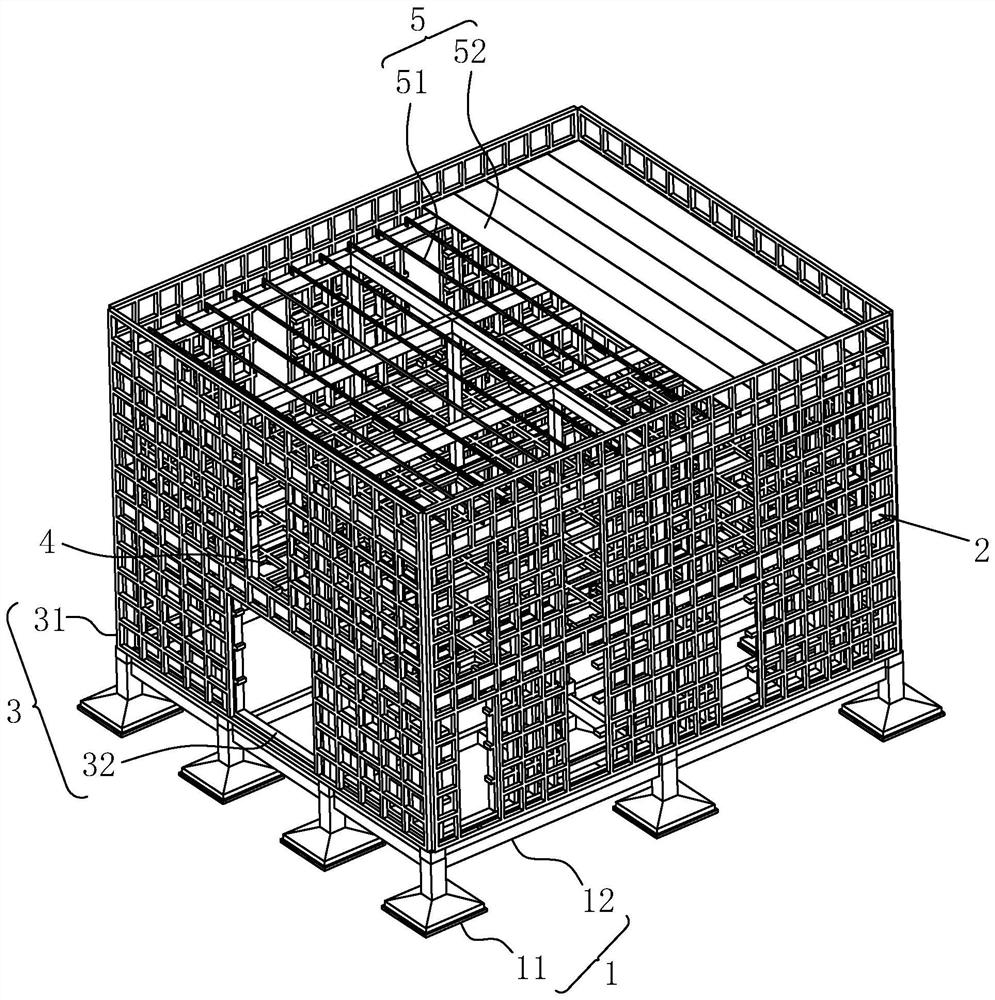

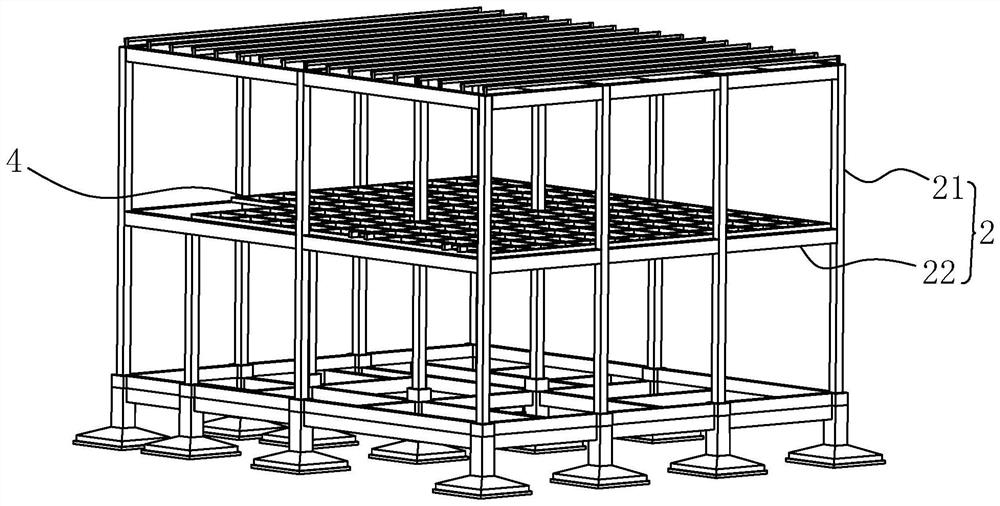

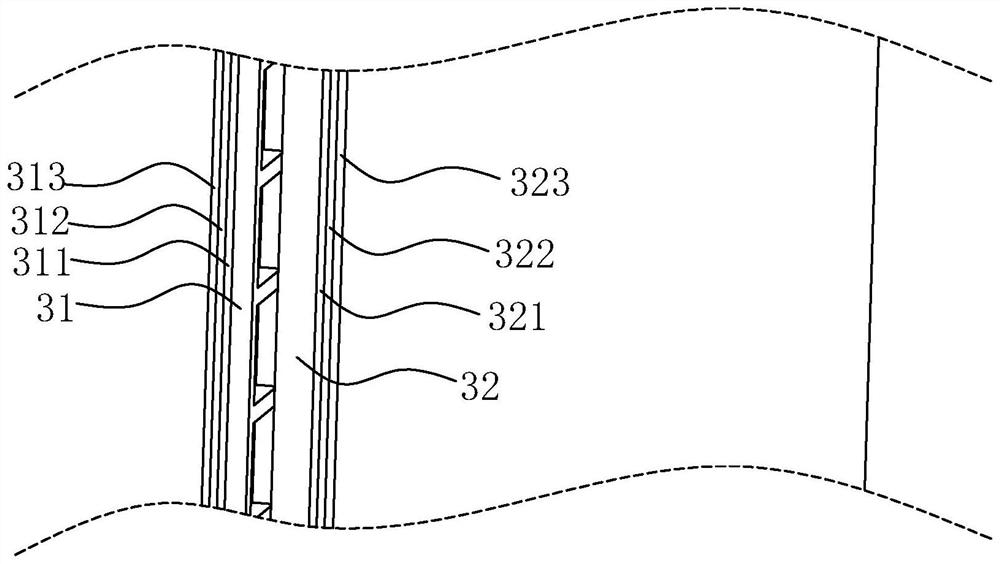

[0036] Embodiment 1, with reference to figure 1 , a prefabricated steel structure building, comprising a base structure 1, a main steel frame 2, a wall truss 3, a floor truss 4 and a roof structure 5, the base structure 1 is arranged under the main steel frame 2, and the wall truss 3 is vertically It is installed in the main frame to cooperate with the main steel frame 2 to divide the outdoor space and the indoor space. The floor truss 4 is horizontally installed inside the main steel frame 2 to divide the inside of the main steel frame 2 into upper and lower floors. The roof structure 5 is set The upper end of the main steel frame 2 is used to cap the upper end of the main steel frame 2 .

[0037] refer to figure 2 , the main steel frame 2 includes a plurality of vertical support rods 21 and a plurality of horizontal support rods 22, the vertical support rods 21 are square steel structures, the horizontal support rods 22 are I-shaped steel structures, and the two ends of th...

Embodiment 2

[0048] Embodiment two, refer to Figure 4 and Figure 5 , the difference from Embodiment 1 is that the base ring beam 12 is provided with a moving part 121 at a position opposite to the independent foundation 11 up and down for driving the base ring beam 12 to move horizontally, so that the distance between the base ring beam 12 and the independent foundation 11 The connection between them is no longer a fixed connection, but the foundation ring beam 12 can move horizontally on the independent foundation 11. At this time, the foundation ring beam 12 and the part above the foundation ring beam 12 will be changed when the position needs to change. It is more convenient, and it is no longer necessary to move by means of demolition.

[0049] refer to Figure 4 and Figure 5 The moving part 121 includes a support block 1211 and a roller 1212. The support block 1211 is in the shape of a cuboid and is made of concrete. The upper end of the support block 1211 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com