Belt tensioning device and belt conveyor applying same

A belt conveyor and tensioning device technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of narrowing the application field, inconvenient site layout, and application field restrictions, and achieve flexible setting, convenient production, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the purpose, structure and function of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

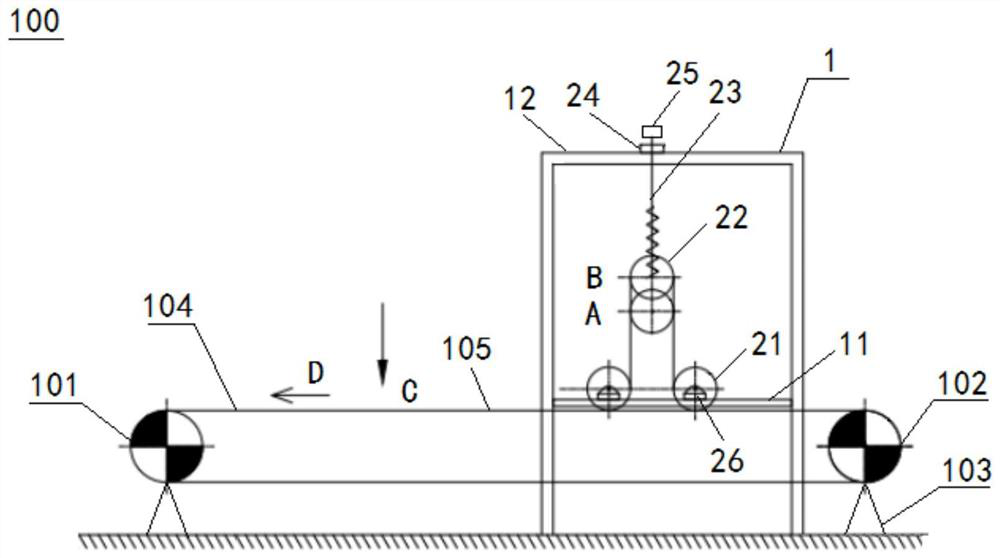

[0021] figure 1 The structure of the belt tensioning device according to the embodiment of the present invention is shown. The belt tensioning device includes: a fixed frame 1 and an adjusting device fixed in the fixed frame 1, the adjusting device includes a pair of fixed steering rollers 21 fixed in the fixed frame, and a tensioning roller 22 positioned above the pair of fixed steering rollers 21 , and the spiral tension rod assembly, one end of the spiral tension rod assembly is connected to the tension drum 22, and the other end is connected to the fixed frame 1, wherein the adjustment device is connected to the upper belt surface 105 of the belt 104 of the belt conveyor 100, After the upper belt surface 105 passes through the first fixed turning roller and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com